Hollow mesoporous silica bead-polymer hybrid ultrafiltration membrane and preparation method thereof

A technology of mesoporous silica and silica, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of limiting membrane permeation flux and improving, and achieve simple operation process and excellent reaction conditions Mild, stable film structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] First, 0.1 parts by weight of hollow mesoporous silica spheres (the size of the hollow core is about 500 nm, the wall thickness is about 80 nm, and the mesopore diameter is about 2.7 nm) is dispersed in 37 parts by weight of N-methylpyrrolidone (NMP ), then 10 parts by weight of brominated polyphenylene ether was dissolved therein, and then the NMP solution of 2.0 mol / L triethanolamine was added dropwise for quaternization, and the molar ratio of brominated polyphenylene ether repeating unit to triethanolamine was 8:1, after electromagnetic stirring for 30 minutes and ultrasonic for 60 minutes, the prepared casting solution was left to defoam, and then directly coated on a clean glass plate with a glass rod; the glass plate was placed horizontally and immersed in a 30°C Gel bath (water bath) for 2 h, the prepared membrane was washed with a large amount of water to remove the residual solvent in the membrane, and stored in water.

[0021] Under the operating pressure of ...

Embodiment 2-4

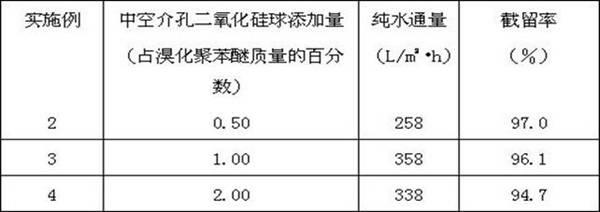

[0023] As in Example 1, according to the above method, the hollow mesoporous silica spheres used have a hollow core size of about 500 nm, a wall thickness of about 80 nm, and a mesopore diameter of about 2.7 nm, and 37 In the N-methylpyrrolidone (NMP) of parts by weight, the brominated polyphenylene ether of 10 parts by weight is dissolved wherein again, then the NMP solution of the triethanolamine of 2.0 mol / L is added dropwise to carry out quaternization, brominated polyphenylene The molar ratio of ether repeating unit to triethanolamine is 8:1. After stirring and ultrasonication, it is coated and formed into a film by phase inversion. Under the operating pressure of 0.2 MPa, the pure water flux of the membrane and the rejection rate of 0.5 g / L ovalbumin aqueous solution were tested.

[0024] These several examples are to investigate the influence of different hollow mesoporous silica sphere contents on the prepared hollow mesoporous silica sphere-polymer hybrid ultrafiltrat...

Embodiment 5-7

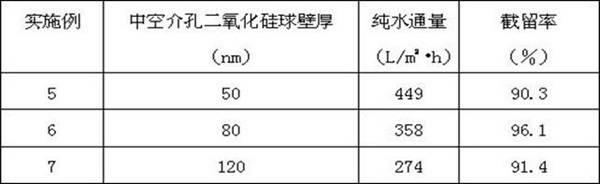

[0028] As in Example 1, according to the above method, the hollow mesoporous silica spheres used have a hollow core size of about 500 nm, a wall thickness of about 50-120 nm, and a mesoporous diameter of about 2.7 nm. Add 37 In the N-methylpyrrolidone (NMP) of parts by weight, the brominated polyphenylene ether of 10 parts by weight is dissolved wherein again, then the NMP solution of the triethanolamine of 2.0 mol / L is added dropwise to carry out quaternization, brominated polyphenylene The molar ratio of ether repeating unit to triethanolamine is 8:1. After stirring and ultrasonication, it is coated and formed into a film by phase inversion. Under the operating pressure of 0.2 MPa, the pure water flux of the membrane and the rejection rate of 0.5 g / L ovalbumin aqueous solution were tested.

[0029] These several examples are to investigate the influence of different wall thicknesses of hollow mesoporous silica spheres on the prepared hollow mesoporous silica sphere-polymer h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com