Method for recycling chromium from chromium passivation wastewater of electrolytic manganese factory

A technology of wastewater recovery and chromium passivation, applied in chemical instruments and methods, chromium compounds, inorganic chemistry, etc., can solve the problems of low wastewater reuse rate and low chromium recovery rate, achieve high chromium recovery rate, improve purity and The effect of product quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

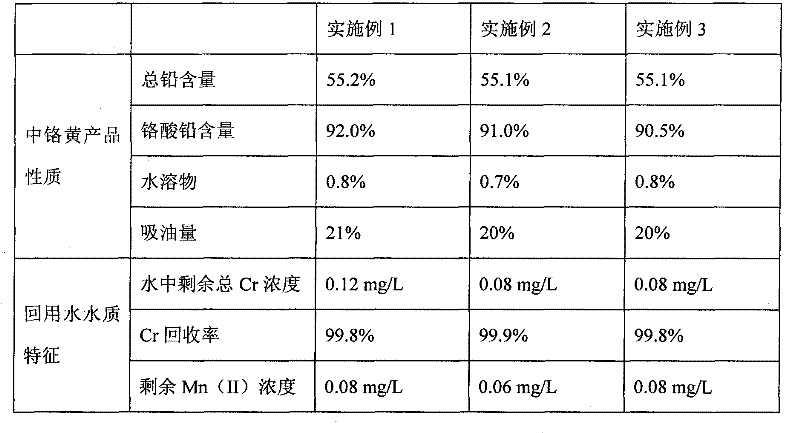

Embodiment 1

[0024] The wastewater is taken from the chromium passivation cleaning wastewater of Daxin Electrolytic Manganese Plant of CITIC Dameng Mining Co., Ltd. The total chromium content in the wastewater is 80mg / L, and the manganese ion content is 300mg / L. First add 1.5mL of 30wt% hydrogen peroxide to 1L of waste water, stir and react, the mixer speed is 60 rpm, the oxidation reaction time is 20min, Cr(III) is oxidized to Cr(VI), and the recovery rate of Cr is improved; then add 5wt% sodium hydroxide adjusts the pH value to 9.0, precipitates for 50min, and separates solid and liquid to remove impurity metal ions such as Mn in the wastewater to improve the purity and quality of chromium recovery products; then add 5wt% sulfuric acid to adjust the pH value to 5.5 ;

[0025] Add 0.1mol / L of Pb 2+ (Pb(NO 3 ) 2 ) 16.8mL, stirred and reacted for 20min, the reaction temperature was controlled at 58°C, and then precipitated for 60min;

[0026] The solid phase part obtained by the precipi...

Embodiment 2

[0029] The wastewater is taken from the chromium passivation cleaning wastewater of Daxin Electrolytic Manganese Plant of CITIC Dameng Mining Co., Ltd. The total chromium content in the wastewater is 74mg / L, and the manganese ion content is 260mg / L. First add 1.2mL of 30wt% hydrogen peroxide to 1L of waste water, stir and react, the mixer speed is 75 rpm, the oxidation reaction time is 15min, Cr(III) is oxidized to Cr(VI), and the recovery rate of Cr is improved; then add Adjust the pH value to 8.0 with 2wt% sodium hydroxide, precipitate for 40 minutes, and separate solid and liquid to remove impurity metal ions such as Mn in the wastewater to improve the purity and quality of the chromium recovery product; then add 2wt% sulfuric acid to adjust the pH value to 4.0;

[0030] Add 0.1mol / L of Pb 2+ (Pb(NO 3 ) 2 ) 15.1mL, stirred and reacted for 30min, the reaction temperature was controlled at 55°C, and then precipitated for 55min;

[0031] The solid phase part obtained by the...

Embodiment 3

[0034] The wastewater is taken from the chromium passivation cleaning wastewater of Daxin Electrolytic Manganese Plant of CITIC Dameng Mining Co., Ltd. The total chromium content in the wastewater is 68mg / L, and the manganese ion content is 266mg / L.

[0035] First add 1mL of 30wt% hydrogen peroxide to 1L of waste water, stir and react, the mixer speed is 90 rpm, the oxidation reaction time is 25min, Cr(III) is oxidized to Cr(VI), and the recovery rate of Cr is improved; then add 3wt% % sodium hydroxide adjusts the pH value to 10.0, precipitates for 60min, and separates the solid and liquid to remove impurity metal ions such as Mn in the waste water to improve the purity and quality of the chromium recovery product; add 3.5wt% sulfuric acid to adjust the pH value to 6.0;

[0036] Add 0.1mol / L of Pb 2+ (Pb(NO 3 ) 2 ) 14.5mL, stirred and reacted for 25min, the reaction temperature was controlled at 60°C, and then precipitated for 40min;

[0037] Wash the solid phase part obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com