Method for preparing polyurethane foam by using jatropha curcas oil-based soft polyether

A technology of jatropha oil and polyurethane soft foam, applied in the field of molecular polymerization, can solve the problem of high price, achieve low cost, reduce cost, and facilitate the purchase of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

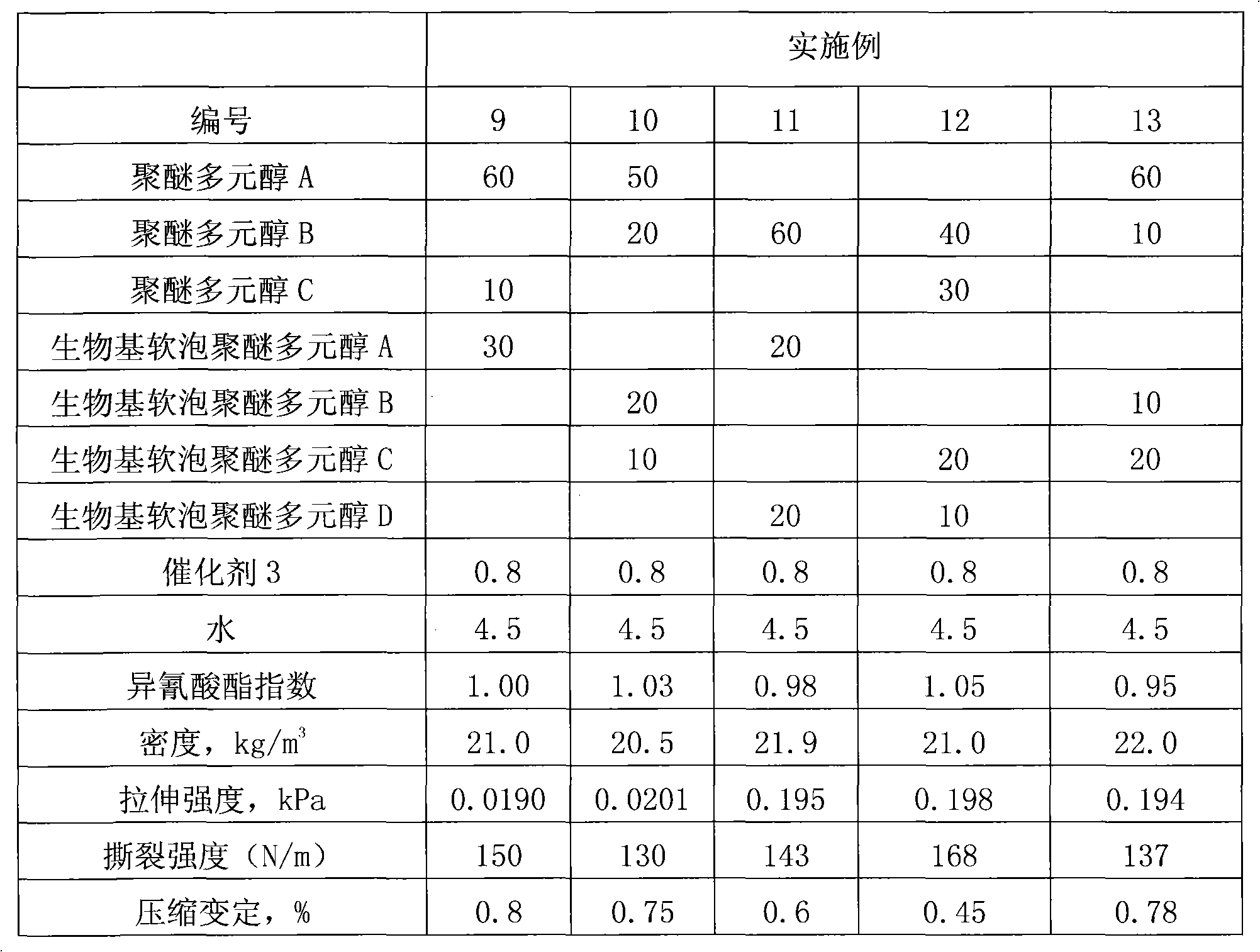

Examples

Embodiment 1

[0023] Add jatropha oil 500g, 80% formic acid 68g in the glass kettle of 1L, stir 10 minutes, dropwise add 30% hydrogen peroxide 230g, the mol ratio of hydrogen peroxide to soybean oil is 3.7, catalyst formic acid is to the ratio of jatropha oil The molar ratio is 2.2, react at 50-55°C for 6 hours, raise the temperature to 100-110°C, reflux for 6 hours, stand still and separate the acid water, wash twice, reduce the pressure and vacuum until the water content is less than 0.10%, and obtain hydroxylated vegetable oil , the hydroxyl value of the product is detected to be 226mgKOH / g, and this product is hydroxy A.

Embodiment 2

[0025] Add jatropha oil 500g, 80% formic acid 60g in a 1L glass kettle, stir for 10 minutes, add dropwise 30% hydrogen peroxide 210g, the mol ratio of hydrogen peroxide to jatropha oil is 3.4, catalyst formic acid can oxidize The molar ratio of the double bond equivalent is 1.9, react at 40-50°C for 5 hours, raise the temperature to 100-105°C, reflux for 4 hours, stand and separate the acid water by layering, wash twice, reduce the pressure and vacuum until the moisture is less than 0.10%, Obtain hydroxylated vegetable oil, detect the hydroxyl value of product 207mgKOH / g, this product is hydroxy B.

Embodiment 3

[0027] In the glass kettle of 1L, add jatropha oil 500g, with 80% formic acid 65g, drip the hydrogen peroxide 240g of 30%, the mol ratio of hydrogen peroxide to jatropha oil is 3.9, the mol ratio of catalyzer formic acid to jatropha oil The ratio is 2.3, react at 48-55°C for 7 hours, raise the temperature to 100-110°C, reflux for 5 hours, stand and separate the acid water by layering, wash with water twice, decompress and vacuum until the water content is less than 0.10%, and get Hydroxylated vegetable oil, the hydroxyl value of the product is detected to be 236mgKOH / g, and this product is hydroxy C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com