Method for producing 1, 3-propanediol through fermentation

A technology of propylene glycol and fermentation liquid, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., to achieve the effects of reducing fermentation production costs, increasing concentration, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Bacterial species: Klebsiell apneumoniae CGMCC1.9131.

[0032] (2) culture medium

[0033] LB medium (g·L -1 ): Yeast powder 5g / L, peptone 10g / L, NaCl 10g / L, agar 10g / L, adjusted to pH 7.0. For short-term preservation and activation of Klebsiella species.

[0034] The seeds and fermentation medium are shown in Table 1:

[0035] Table 1 medium composition table (L -1 )

[0036]

[0037] Wherein, the formula of trace element solution is shown in the following table.

[0038] Table 2 Trace element solution formula (L -1 )

[0039]

[0040] (3) Training method:

[0041] A. Seed activation

[0042] The strains preserved from glycerol tubes were inoculated into LB medium slant for activation, and incubated at 37°C for 12 hours to activate the seeds.

[0043] B. Seed cultivation

[0044] Seed culture: 250mL triangular flask sealed with 9 layers of gauze, filled with 100mL of liquid, connected to a ring of slant lawn, aerobic seed culture in a shaker, temper...

Embodiment 2

[0061] (1) strain: with embodiment 1.

[0062] (2) The seed culture medium is the same as in Example 1, and the fermentation medium is the same as in Example 1 except that the concentration of glycerol is 15g / l.

[0063] (3) Training method:

[0064] A. Seed activation

[0065] The strains preserved from glycerol tubes were inoculated into LB medium slant for activation, and incubated at 37°C for 12 hours to activate the seeds.

[0066] B. Seed cultivation

[0067] Seed culture: 250mL triangular flask sealed with 9 layers of gauze, filled with 50mL of liquid, connected to a ring of slant lawn, and carried out aerobic seed cultivation in a shaker at a temperature of 30°C and a speed of 150r min -1 .

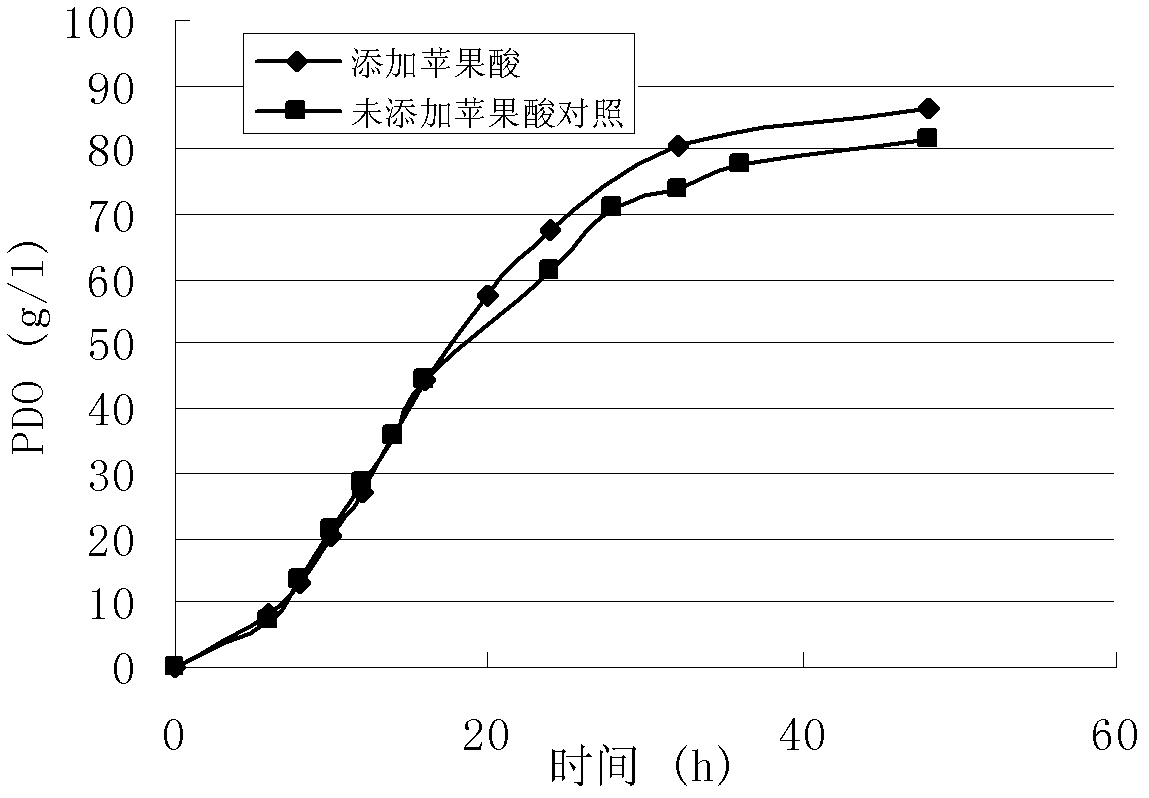

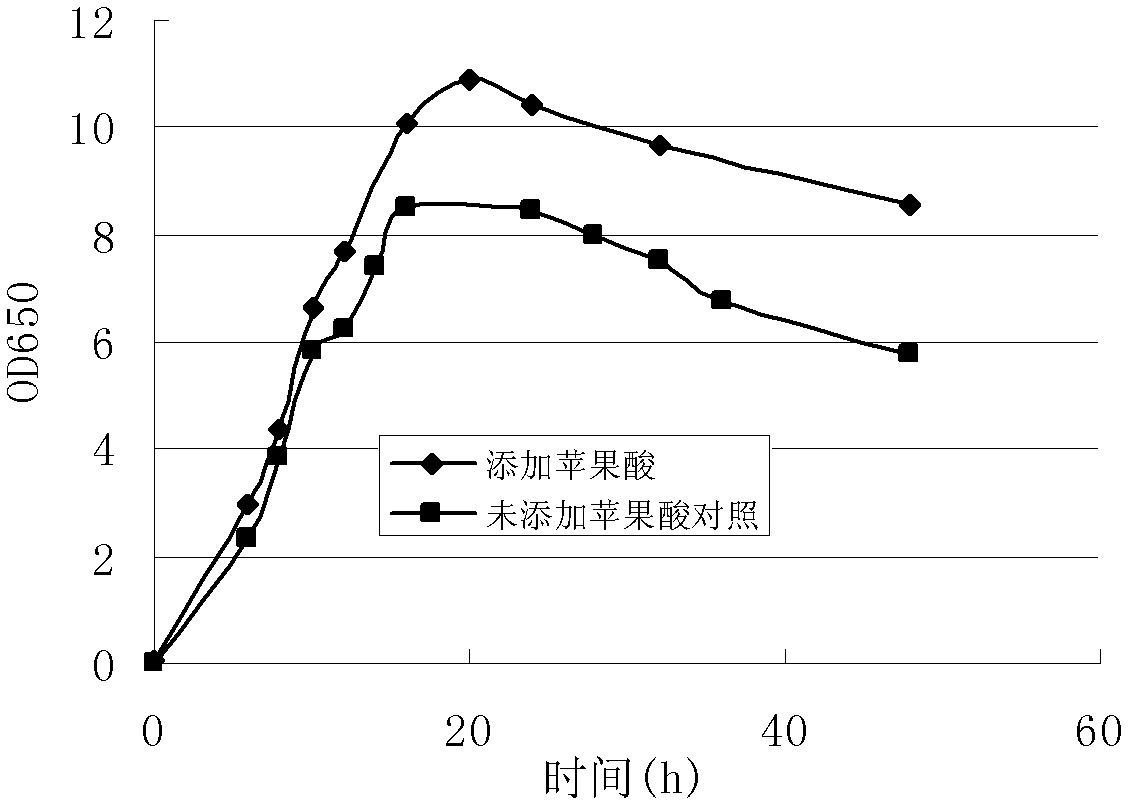

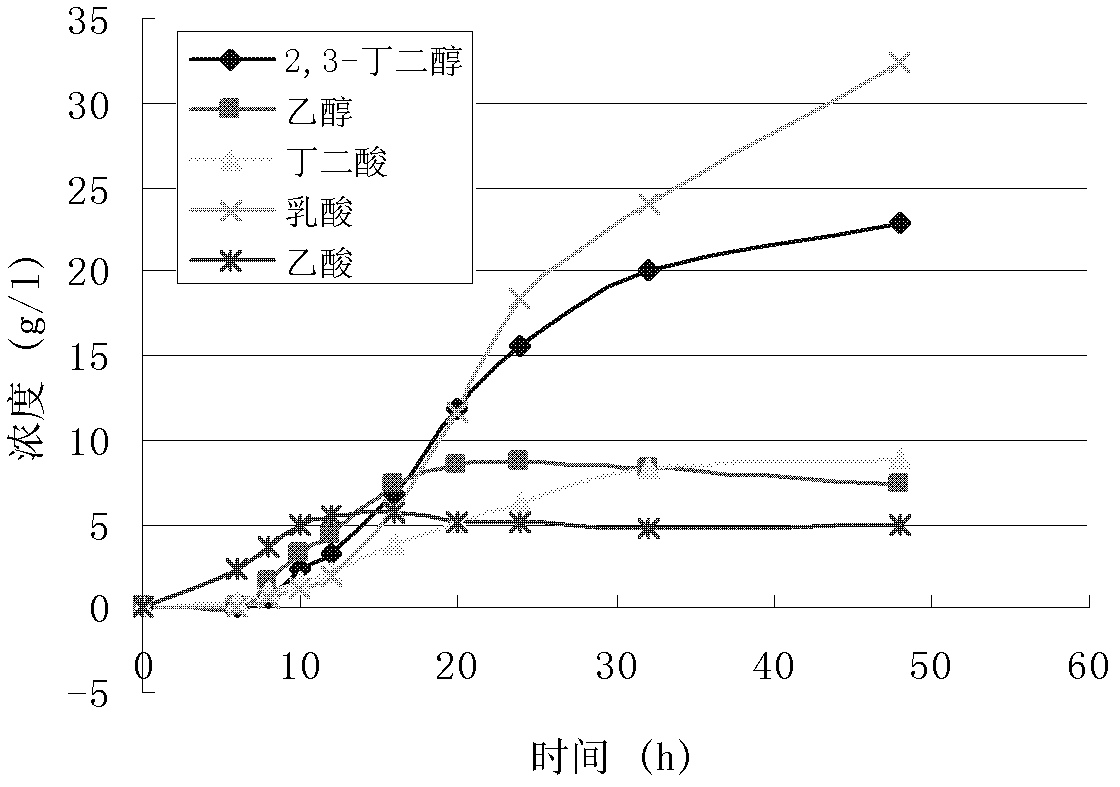

[0068] C. Fermentation culture

[0069] When carried out in a 5L stirred fermenter, the liquid volume is 4L, the inoculum size is 1%, and 0.5vvm air is introduced to carry out the microaerobic fermentation culture, and the stirring speed is 250rpm. Malic acid was added to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com