Method for preparing injection-molding nickel-base ODS (oxide dispersion strengthened) alloy

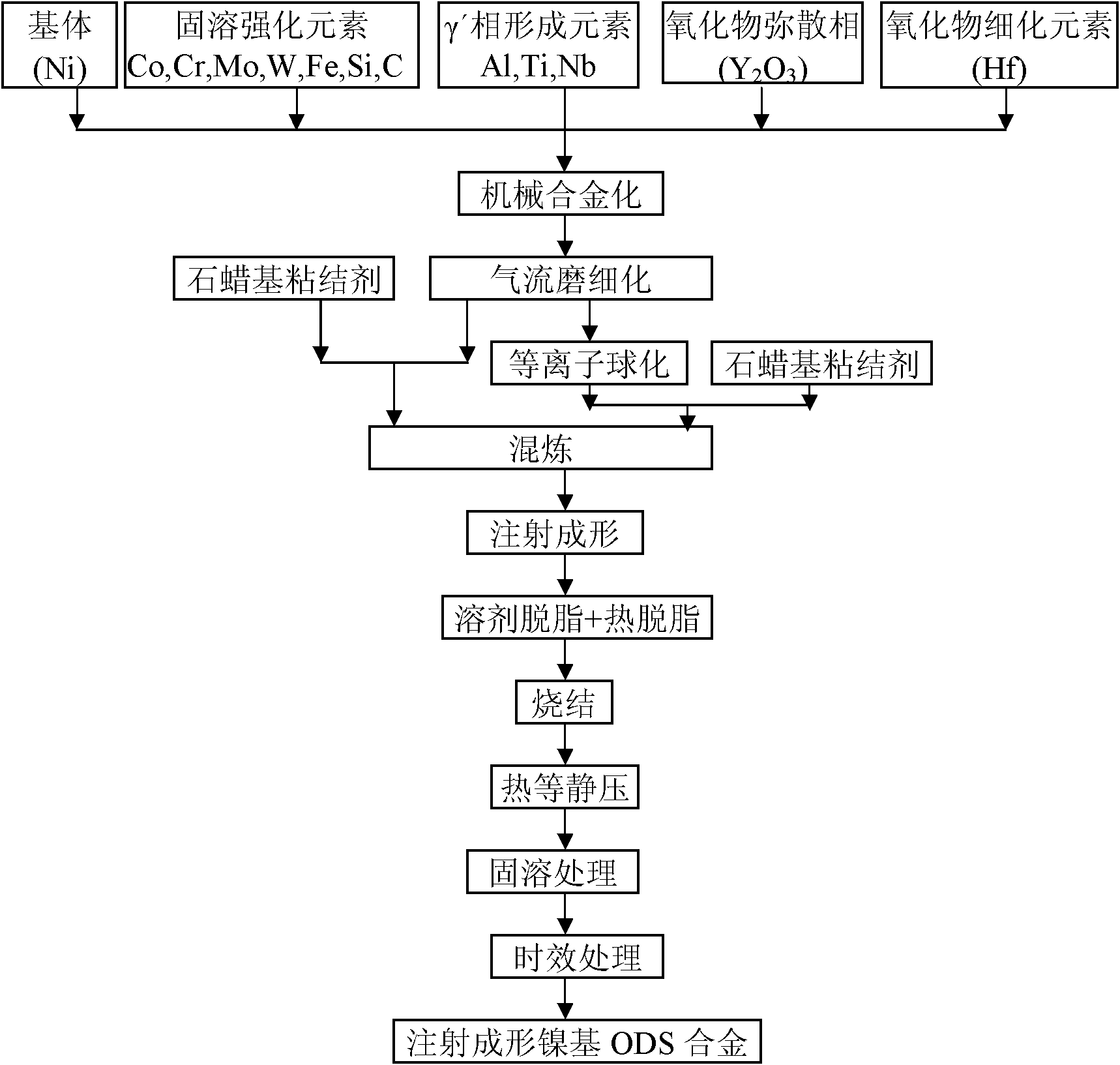

An injection molding, nickel-based alloy technology, applied in the field of powder injection molding, can solve the problems of irregular shape of mechanical alloy powder, unsuitable for injection molding, powder agglomeration, etc., to expand high-temperature mechanical properties, avoid non-metallic inclusions, particle size small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

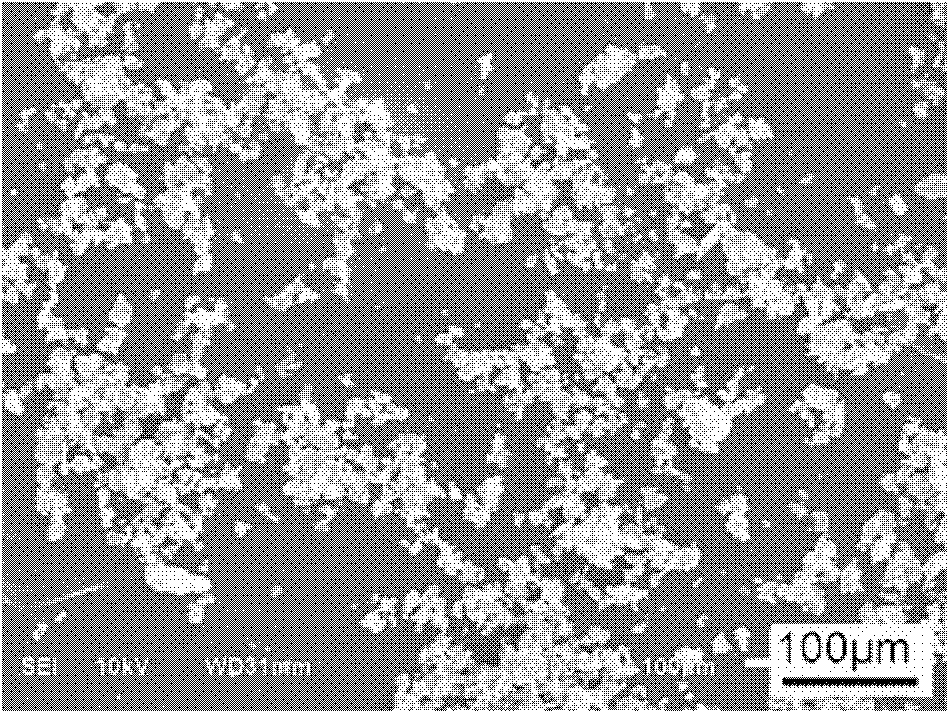

[0026] Example 1: Preparation of Injection Molded Nickel-based ODS Alloy Without γ′ Phase Reinforcement Using Jet Milled Powder as Raw Material

[0027] Y with a particle size of 20-30nm 2 o 3 Granules, and high-purity Ni powder, Cr powder, Co powder, Mo powder, W powder, Fe powder, Si powder, Hf powder and C powder are raw materials, and the mixed powder is prepared according to the following mass percentages: 21% Cr, 1.5% Co, 9% Mo, 0.5% W, 18% Fe, 0.8% Si, 0.09% C, 1% Y 2 o 3 , 1.2% Hf and the balance Ni. First, the mixed powder was subjected to high-energy ball milling in a high-purity Ar atmosphere to make Y 2 o 3 The particles are uniformly dispersed in the Ni matrix, the speed of the ball mill is 380 rpm, and the ball milling time is 40 hours; the mechanical alloy powder is crushed and refined by a jet mill, the air pressure is 6MPa, and the sorting energy frequency is 45Hz, and the average particle size is about 20μm powder; airflow milled powder and binder are e...

Embodiment 2

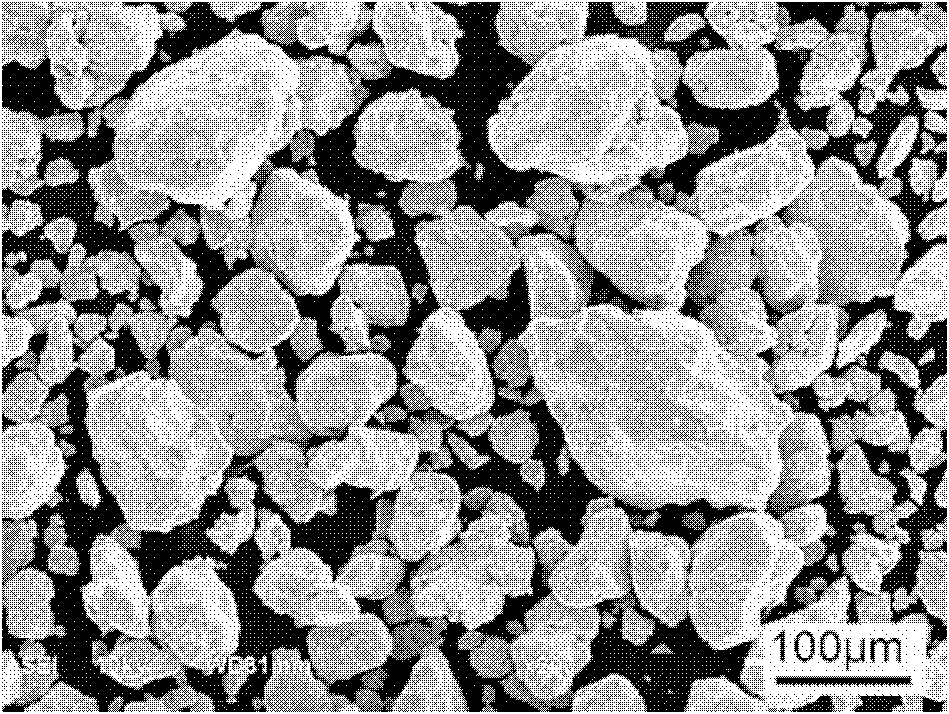

[0028] Example 2: Using plasma spheroidized powder as raw material to prepare injection-molded nickel-based ODS alloy without γ′ phase reinforcement

[0029] Y with a particle size of 20-30nm 2 o 3 Granules, and high-purity Ni powder, Cr powder, Co powder, Mo powder, W powder, Fe powder, Si powder, Hf powder and C powder are raw materials, and the mixed powder is prepared according to the following mass percentages: 19% Cr, 2% Co, 8% Mo, 1% W, 19% Fe, 0.6% Si, 0.08% C, 1% Y 2 o 3 , 1.2% Hf and the balance Ni. First, the mixed powder was subjected to high-energy ball milling in a high-purity Ar atmosphere to make Y 2 o 3 The particles are evenly dispersed in the Ni matrix, the speed of the ball mill is 450 rpm, and the ball milling time is 48 hours; the mechanical alloy powder is crushed and refined by a jet mill, the air pressure is 8MPa, and the sorting energy frequency is 50Hz, and the average particle size is about 30μm powder; the jet milled powder is subjected to plas...

Embodiment 3

[0030] Example 3: Preparation of γ′ and oxide co-reinforced nickel-based ODS alloy for injection molding with jet mill fine powder

[0031] Y with a particle size of 20-30nm 2 o 3 Particles, and high-purity Ni powder, Cr powder, Nb powder, Mo powder, Ti powder, Al powder, Fe powder, Si powder, Hf powder and C powder are raw materials, and the mixed powder is prepared according to the following mass percentage: 18% Cr , 5% Nb, 3% Mo, 0.4% Al, 1% Ti, 19% Fe, 0.3% Si, 0.36% C, 1% Y 2 o 3 , 1.2% Hf and the balance Ni. First, the mixed powder was subjected to high-energy ball milling in a high-purity Ar atmosphere to make Y 2 o 3 The particles are evenly dispersed in the Ni matrix, the speed of the ball mill is 400 rpm, and the ball milling time is 60 hours; the mechanical alloy powder is crushed and refined by a jet mill, the air pressure is 5MPa, and the sorting energy frequency is 40Hz, and the average particle size is about 35μm powder; jet mill fine particle powder and b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com