Environmentally friendly modified bast fiber containing functional structure, and preparation method thereof

It is a technology with green environmental protection and functional structure, which is applied in fiber treatment, plant fiber, textile and paper making, etc. It can solve the problem of low mechanical properties of natural biological hemp fiber/polymer composite material, poor polarity and flame retardancy of hemp fiber, surface Fine structural defects and other problems, to achieve the effects of excellent modification effect, improved flame retardancy, and easy control of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

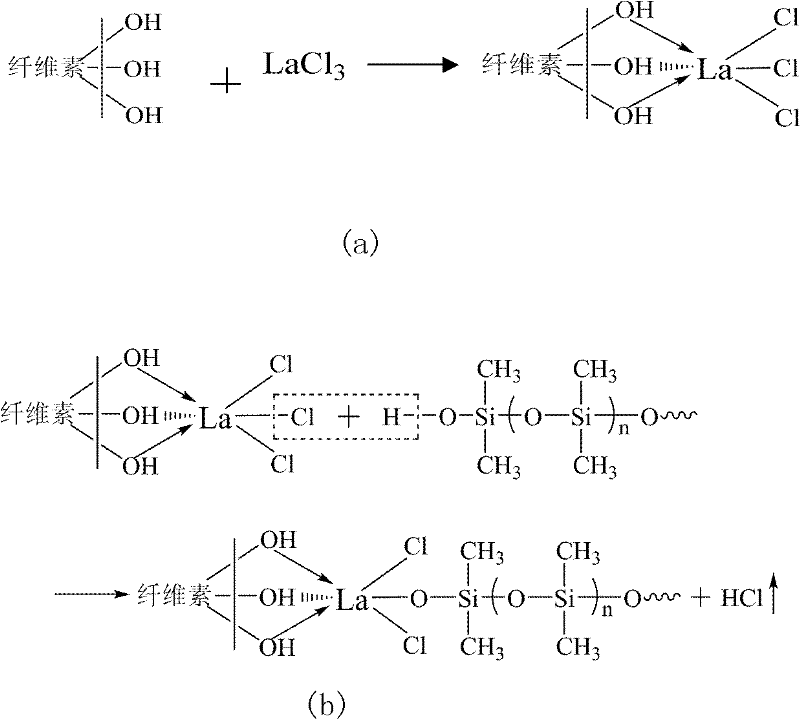

Method used

Image

Examples

Embodiment 1

[0047] 1. Weigh 4.3g of lanthanum chloride (containing 6 crystalline waters), and dissolve the weighed lanthanum chloride into 1500ml of water under medium-speed magnetic stirring until it is completely dissolved;

[0048] 2. Weigh 100g of ramie fiber rinsed with water and dried, put it into the prepared rare earth lanthanum chloride solution, soak it with ultrasonic vibration at 60°C for 1 hour, remove it, and dry it;

[0049] 3. While treating the hemp fiber with the rare earth lanthanum chloride solution, mix amino silicone oil, emulsifier (OP-10), and dispersant (cetyl alcohol) in a ratio of 6:6:1, and ultrasonically vibrate at 60°C Stir vigorously for 1 hour to prepare 500ml silicone oil emulsion.

[0050] 4. Put the ramie fiber treated with rare earth lanthanum chloride into the prepared amino silicone oil emulsion, and add distilled water to 1500ml. Ultrasonic vibration reaction was performed at 80°C for 3 hours (3hr). After the reaction was completed, the treated rami...

Embodiment 2

[0052] 1. Weigh 2.15g of lanthanum chloride, and dissolve the weighed lanthanum chloride into 1500ml of water under medium-speed magnetic stirring until it is completely dissolved;

[0053] 2. Weigh 100g of ramie fiber rinsed with water and dried, put it into the prepared rare earth solution, soak it with ultrasonic vibration at 60°C for 1 hour, remove it and dry it;

[0054] 3. While treating the hemp fiber with the rare earth lanthanum chloride solution, mix the amino silicone oil emulsifier (OP-10) and the dispersant (cetyl alcohol) in a ratio of 5:5:1, and strengthen the ultrasonic vibration at 60°C Vigorously stir for 1 hour, and configure 500ml silicone oil emulsion.

[0055] 4. Put the ramie fiber treated with rare earth lanthanum chloride into the prepared amino silicone oil emulsion, and add distilled water to 1500ml. Ultrasonic vibration reaction was performed at 80°C for 2 hours (2hr). After the reaction was completed, the treated ramie was air-dried or dried in a ...

Embodiment 3

[0057] 1. Weigh 8.6g of lanthanum chloride (containing 6 crystal waters), dissolve the weighed lanthanum chloride into 1500ml of water under medium-speed magnetic stirring and continue stirring until completely dissolved;

[0058] 2. Weigh 100g of ramie fiber rinsed with water and dried, put it into the prepared rare earth lanthanum chloride solution, soak it with ultrasonic vibration at 60°C for 1 hour, remove it, and dry it;

[0059] 3. While treating the hemp fiber with the rare earth lanthanum chloride solution, mix the amino silicone oil emulsifier (OP-10) and the dispersant (cetyl alcohol) in a ratio of 5:5:1, and strengthen the ultrasonic vibration at 60°C Vigorously stir for 1 hour, and configure 500ml silicone oil emulsion.

[0060] 4. Put the ramie fiber treated with rare earth lanthanum chloride into the prepared amino silicone oil emulsion, and add distilled water to 1500ml. Ultrasonic vibration reaction was performed at 80°C for 3 hours (3hr). After the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com