Mixed thermal force closed type heat extraction cycle heat engine and power generation device

A technology of regenerative cycle and power generation device, which is applied in the field of hybrid thermodynamic closed regenerative cycle heat engine and power generation device, which can solve the problem of reduced efficiency of closed regenerative cycle heat engine, difficult handling of sealing activities, no literature and reports found, etc. problem, to achieve the effect of strong retraction force, increased maintenance cost, and increased retraction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

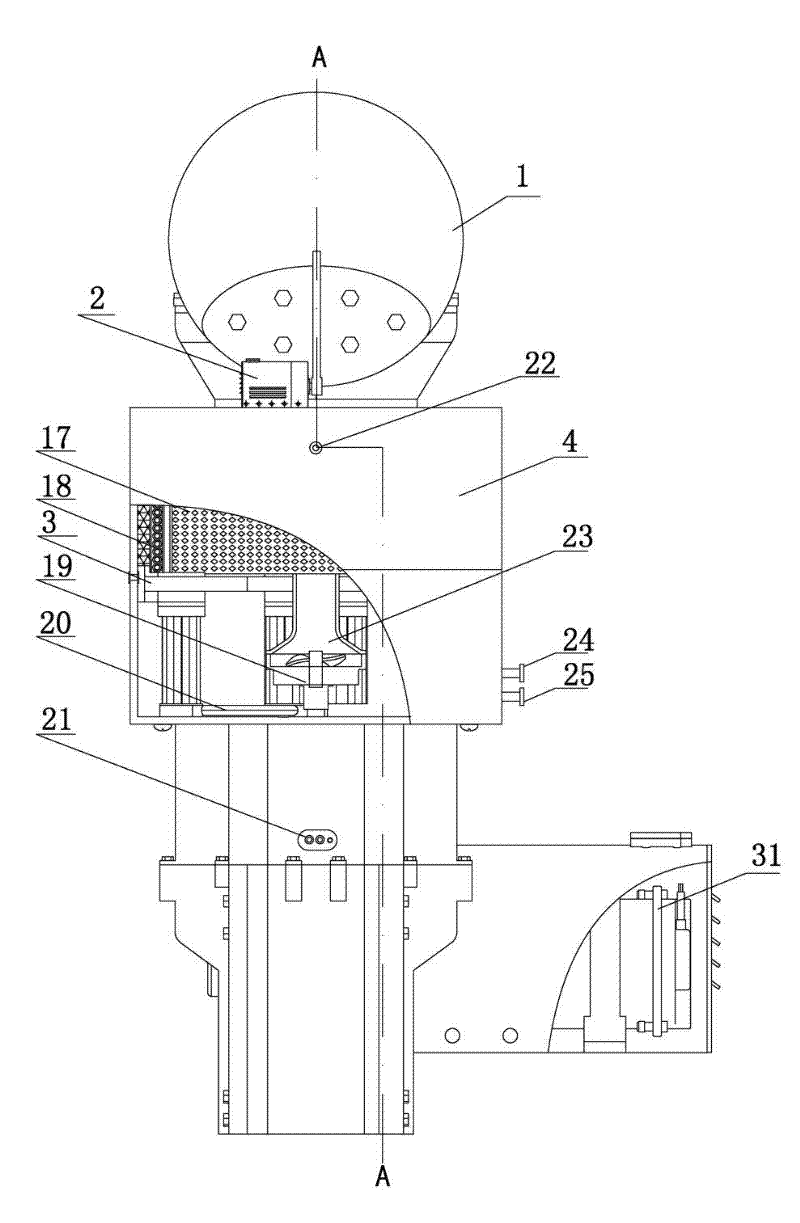

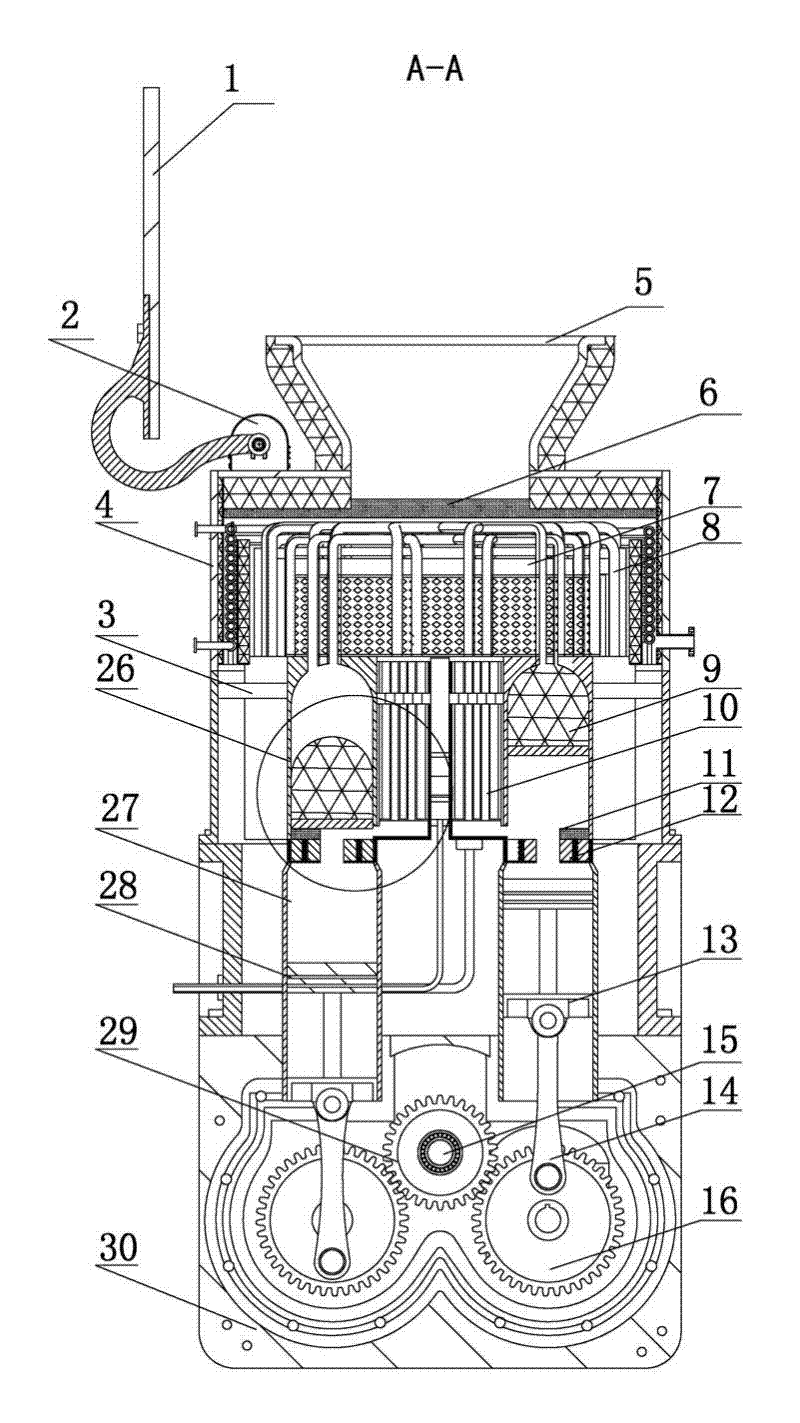

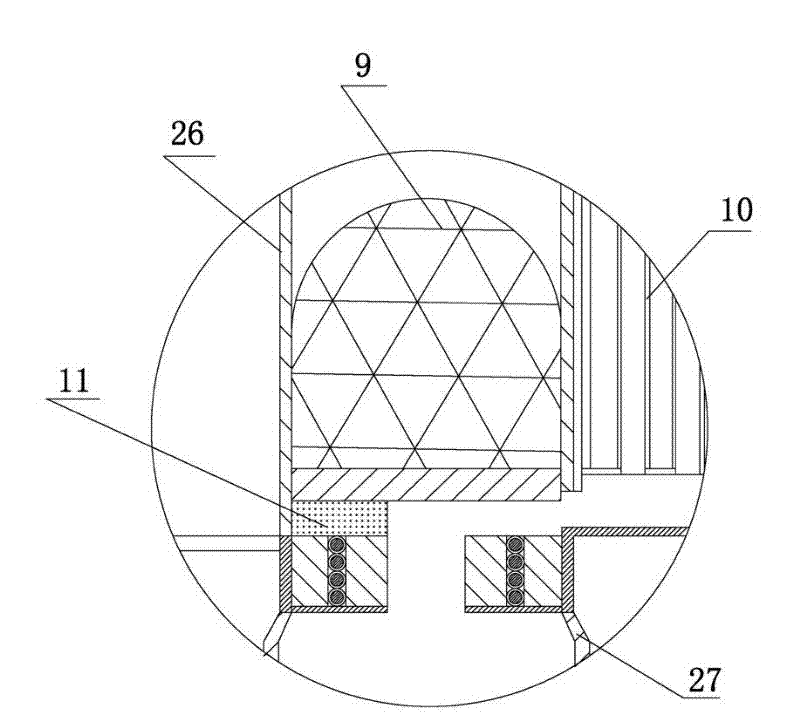

[0039] Refer to attached Figure 1~3 , The present invention's hybrid thermal closed-type regenerative cycle heat engine and power generation device is composed of dual heat source heating components, cycle heat engine components, variable speed and power generation components.

[0040] The dual heat source heating assembly includes barrel wall 4, punching bottom plate 3, heat preservation upper sealing plate, heat energy reflection plate, light receiving port 5, automatic shading cover 1, shading cover motor 2, metal upper cover plate 6, and metal lower cover plate 7 , Porous metal fiber combustion head 17, igniter 23, burner base 19, fuel pipe inlet 21, waste heat recovery pipe 18, waste heat recovery pipe outlet 22, waste heat recovery pipe inlet, exhaust pipe outlet.

[0041] The barrel wall 4 is connected with the punching bottom plate 3, the heat preservation upper sealing plate, and rivets to form a complete barrel body. The insulation layer and the heat reflection pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com