Method for measuring polyepoxysuccinic acid content of circulating cooling water by pinacyanol chloride spectrophotometric method

A technology of polyepoxysuccinic acid and chlorinated pinacol, which is applied to the measurement of color/spectral properties, preparation of samples for testing, etc. , protect the environment, and promote the effect of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

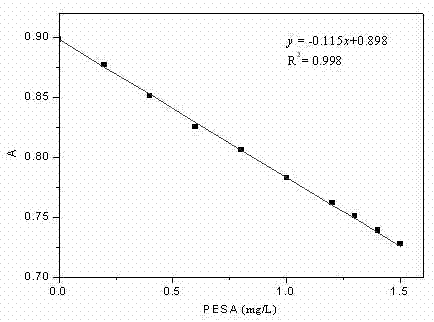

[0037] Embodiment 1: the standard curve of polyepoxysuccinic acid concentration and absorbance relation

[0038] The establishment of the standard curve is carried out as follows:

[0039] (1) Solution preparation:

[0040] Preparation of standard solution of pinacyanohydrin chloride: Weigh 0.1665g of pinacyanin chloride, add 250ml of methanol and 750ml of ethylene glycol into the mixed solution, shake fully, and place in a brown bottle to obtain 4.25×10 -4 The standard solution of pinacyanin chloride in mol / L is stored at 4°C.

[0041] Preparation of polyepoxysuccinic acid standard solution: Weigh 100 mg polyepoxysuccinic acid, dilute to 1000 ml with water, and shake fully to obtain 100 mg / L polyepoxysuccinic acid standard solution.

[0042] Preparation of borax-sodium bicarbonate buffer solution with pH 9.40: Measure 50ml of 0.05mol / L borax solution and 11ml of 0.2mol / L sodium hydroxide solution, add water to dilute to 200ml, shake well, and mix well.

[0043] (2) Standa...

Embodiment 2

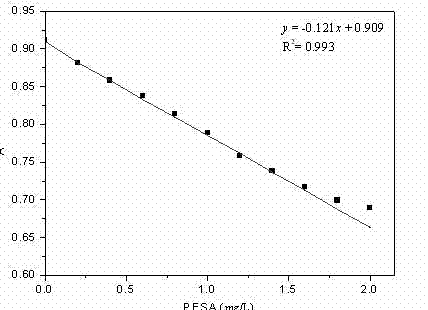

[0046] Embodiment 2: the typical curve of polyepoxysuccinic acid concentration and absorbance relation

[0047] Step is with embodiment 1.

[0048] The polyepoxysuccinic acid standard solution volume and test result of measuring 100mg / L are shown in Table 2, figure 2 A standard curve of absorbance versus polyepoxysuccinic acid concentration is shown. The results show that: when the concentration of polyepoxysuccinic acid is between 0 and 2.0 mg / L, the linear regression equation has better linearity, and its R 2 =0.993. When the concentration of polyepoxysuccinic acid is between 0 and 1.5 mg / L, the linear regression equation has better linearity, and its R 2 =0.997.

[0049]

[0050] Table 2: 0~2.0 mg / L polyepoxysuccinic acid (PESA) standard curve

[0051]

Embodiment 3

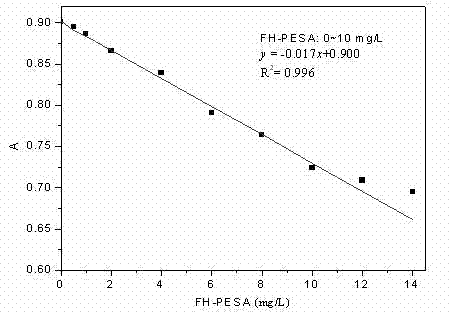

[0052] Embodiment 3: the mensuration of the polyepoxysuccinic acid concentration in the industrial circulating cooling water system

[0053] This embodiment is applicable to a system with polyepoxysuccinic acid standard samples.

[0054] The water samples tested in this example are taken from the circulating cooling water system of a steel plant, which uses polyepoxysuccinic acid, a phosphorus-free scale inhibitor and dispersant. Take circulating cooling water sample V ml, put it in a 100ml volumetric flask, add 2ml of buffer solution, add water to dilute to the mark, shake well, add 4.25×10 -4 2 ml of mol / L standard solution of pinacyanin chloride, develop color for five minutes, and measure absorbance at 600 nm. Each absorbance was measured three times and the average value was taken. By bringing the measured values into the regression equation, the concentration C of polyepoxysuccinic acid in the diluted sample can be estimated.

[0055] The formula for calculating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com