Pixel structure of blue-phase liquid crystal display

A blue-phase liquid crystal and pixel structure technology, applied in the field of pixel structure, can solve problems such as panel display failure, difficult process, short circuit between upper and lower substrates, etc., to avoid signal delay from affecting screen display, improve quality, and reduce operating voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

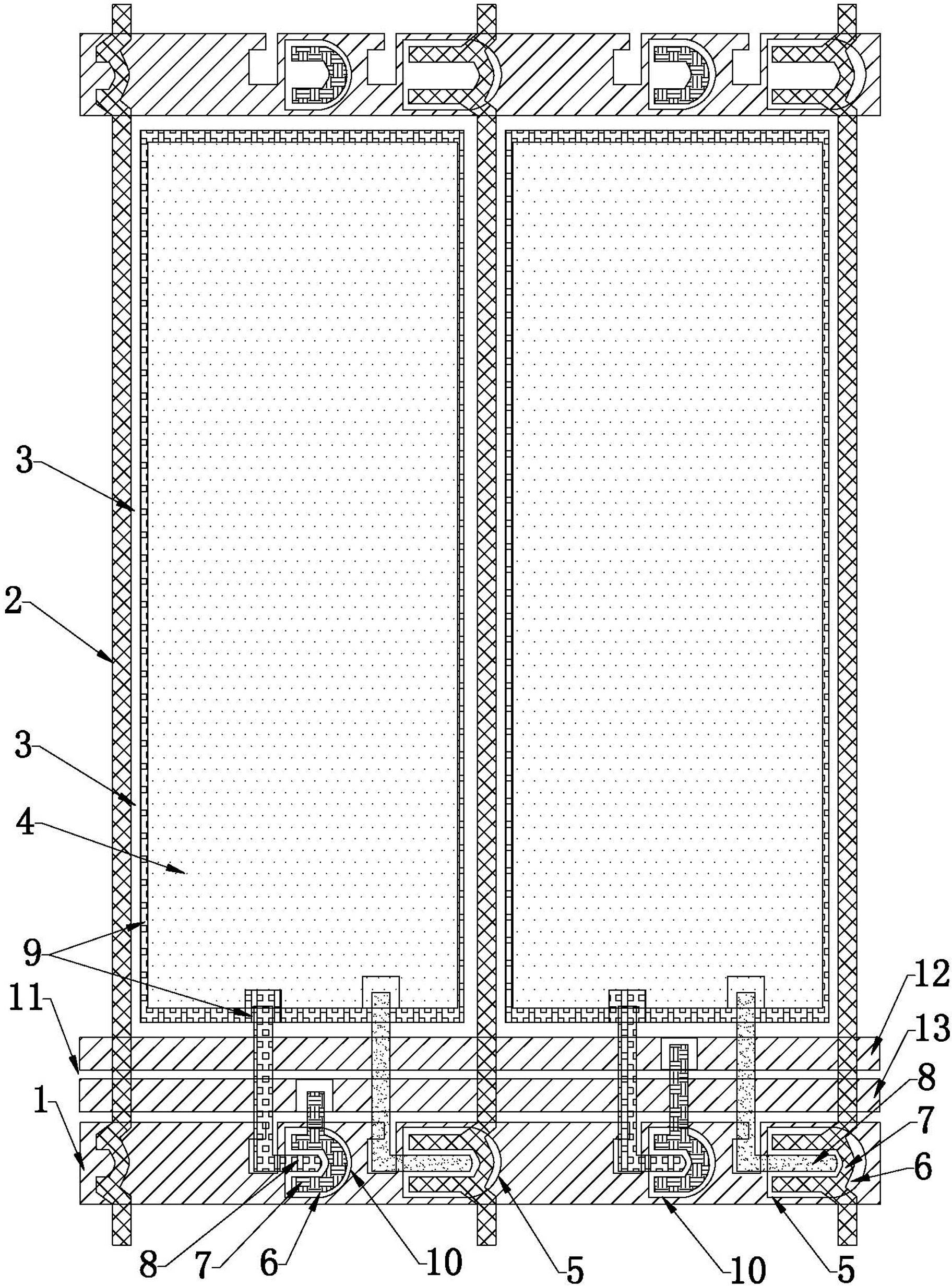

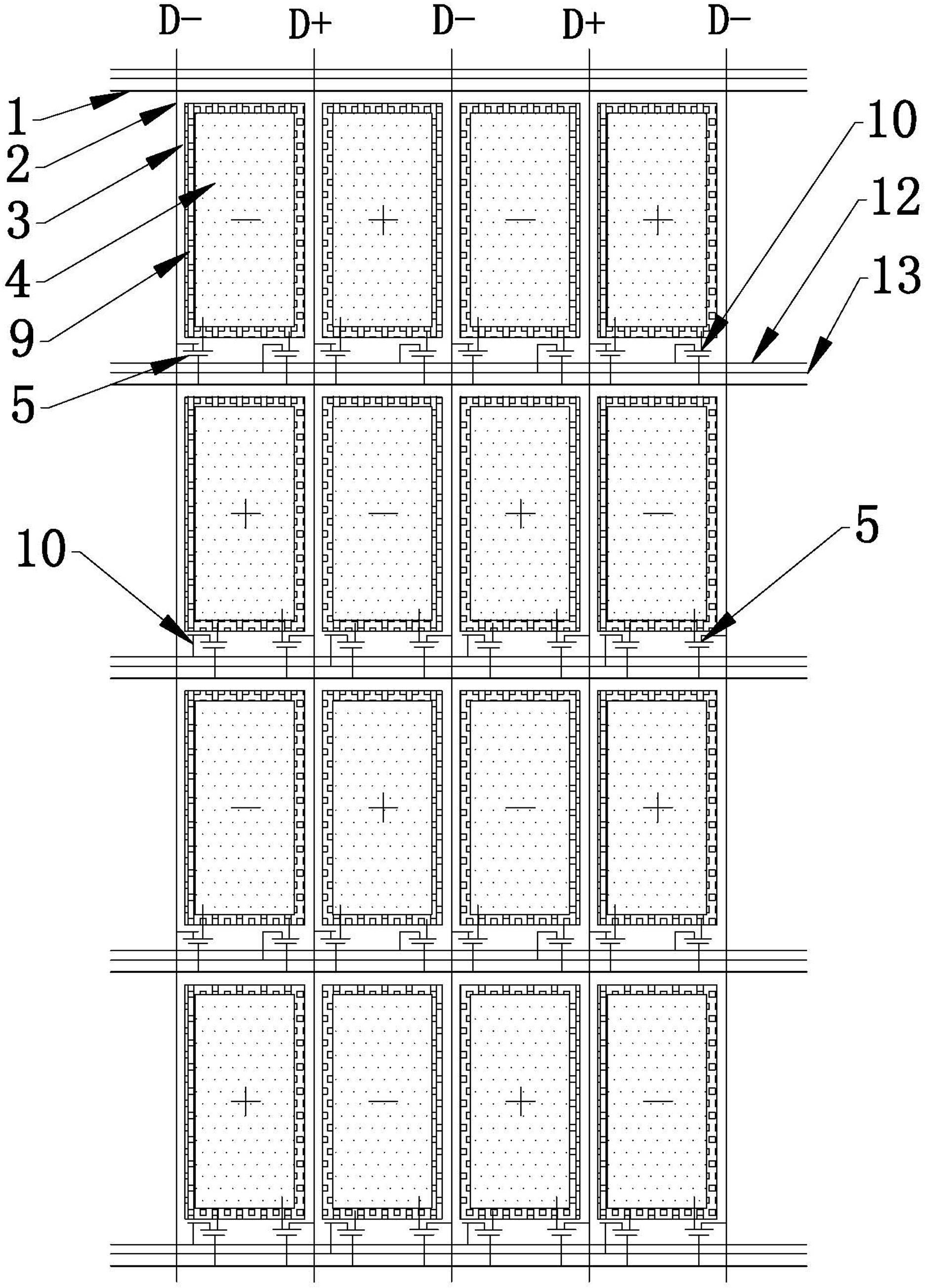

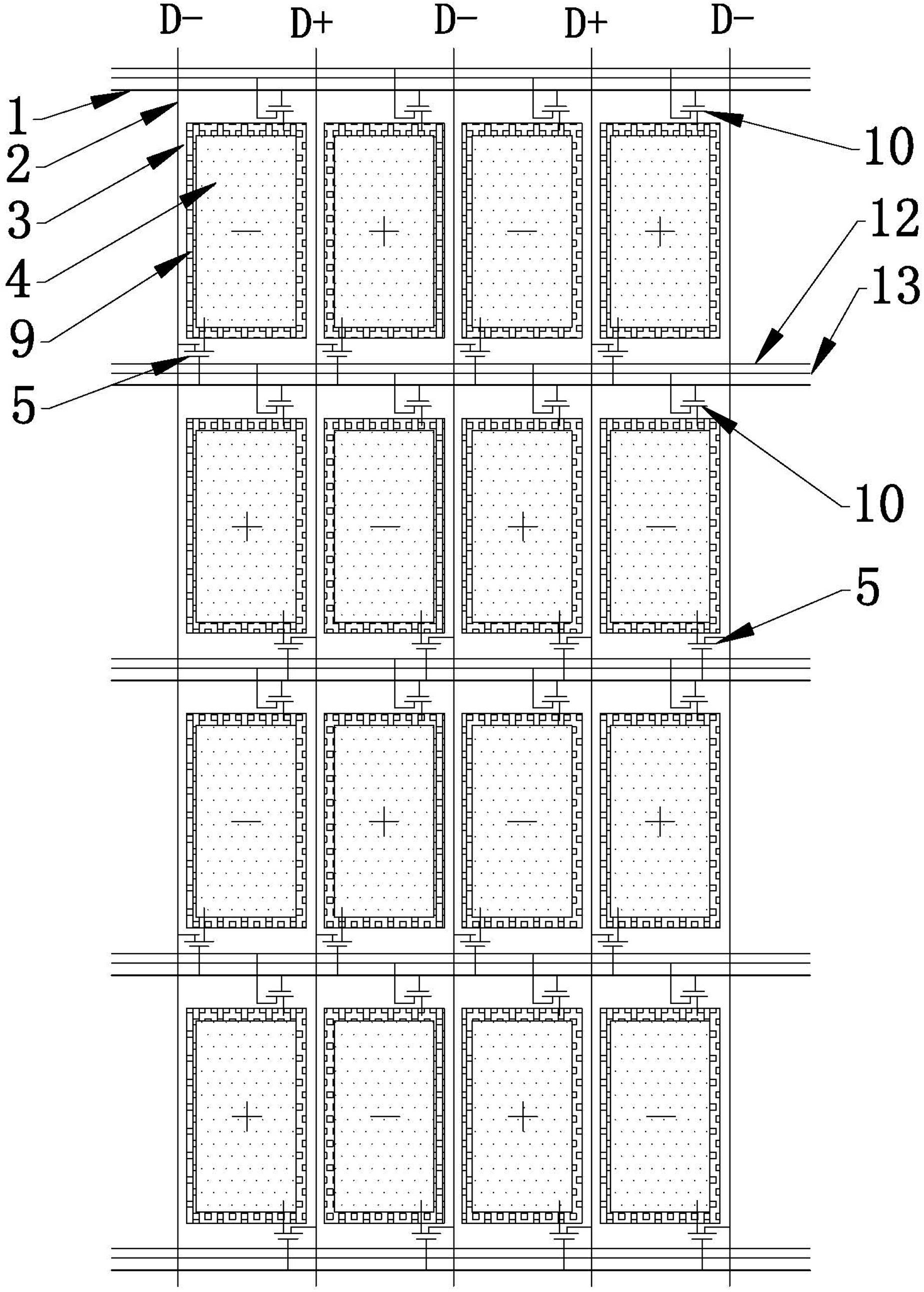

[0025] Such as Figure 1-3 Shown: a pixel structure of a blue-phase liquid crystal display, including a plurality of scanning lines 1 and data lines 2 vertically intersecting and a plurality of pixel units 3 defined by the scanning lines 1 and data lines 2, and the pixel unit 3 is equipped with The pixel electrode 4 and the first TFT 5 driving the pixel electrode 4 , the gate 6 , source 7 and drain 8 of the first TFT 5 are electrically connected to the scan line 1 , the data line 2 and the pixel electrode 4 respectively. In the pixel unit 3, there are also a common electrode 9 positioned at the lower side of the pixel electrode 4 and a second thin film transistor 10 for driving the common electrode 9. The second thin film transistor 10 and the first thin film transistor 5 are alternately arranged, and the second thin film transistor The gate 6, source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com