Attachment of a high-z focal track layer to a carbon-carbon composite substrate serving as a rotary anode target

一种旋转阳极、碳复合的技术,应用在X射线管叠层靶、X射线管电极、X射线管靶材料等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Hereinafter, a hybrid anode disk structure according to an exemplary embodiment of the present invention will be explained in more detail with reference to the accompanying drawings.

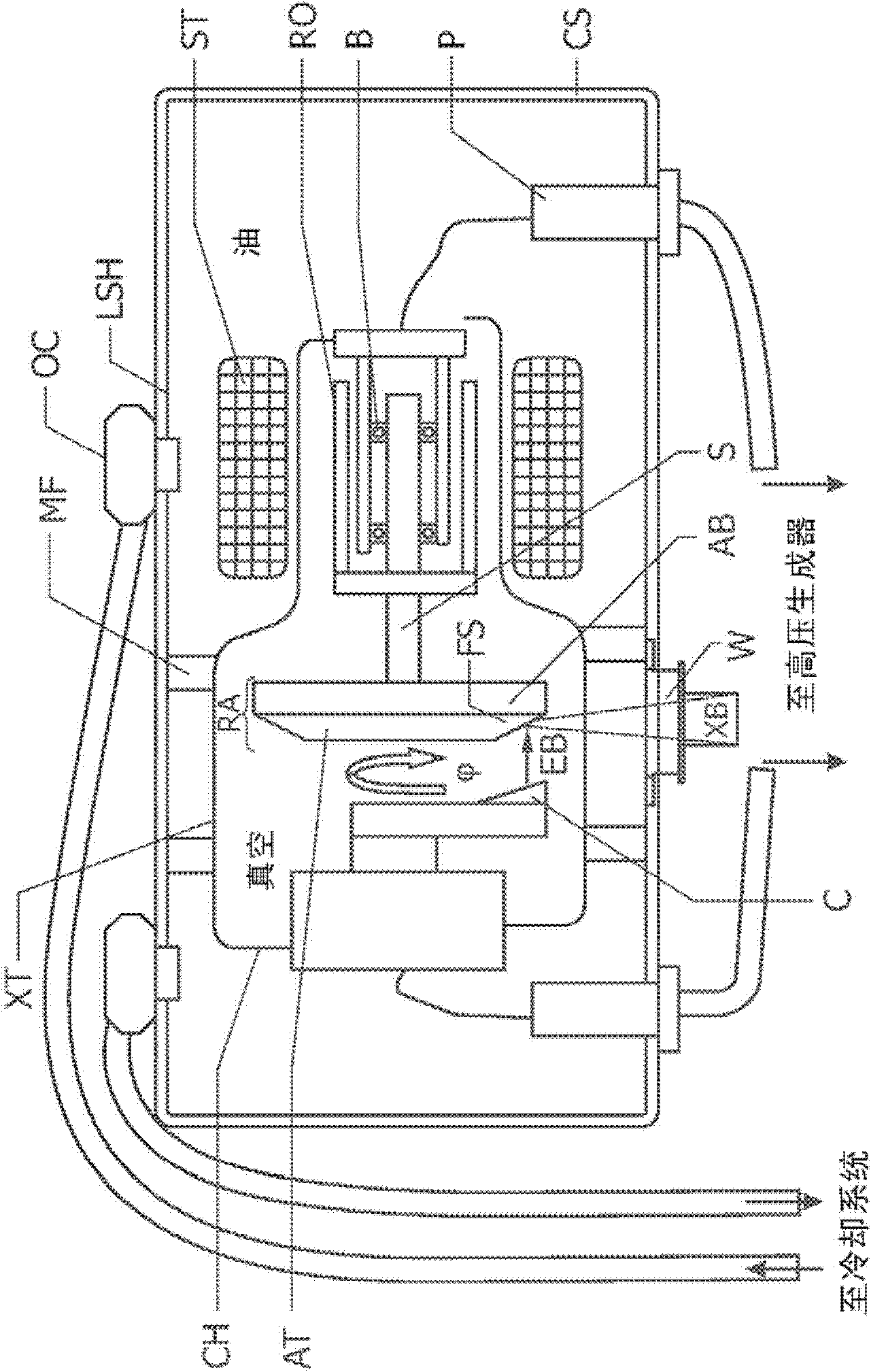

[0051] A schematic cross-sectional view of a conventional rotating anode type X-ray tube as known from the prior art is shown in FIG. 1 . The X-ray tube comprises a stationary cathode C within a vacuum chamber CH given by a glass or metallic glass envelope and a rotatably supported anode target AT fixedly attached to a rotating rod S. When exposed to an electron beam EB with sufficient energy incident on the focal track area on the inclined surface of the anode target, said electrons are ejected from the anode target material due to the high voltage applied between the cathode and said anode, driven by the rotation The anode target AT generates a conical X-ray beam XB and emits the conical X-ray beam XB through the window W of the enclosure CS accommodating the vacuum chamber.

[0052] I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of thermal expansion | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com