A method for continuously preparing hydrogen fluoride with a rotary reactor

A reaction furnace and hydrogen fluoride technology, applied in the direction of fluorine/hydrogen fluoride, etc., can solve the problem that the production capacity of the superphosphate waste gas method cannot be improved, and achieve the effect of solving the shortage of raw material supply, broadening the source of raw materials, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

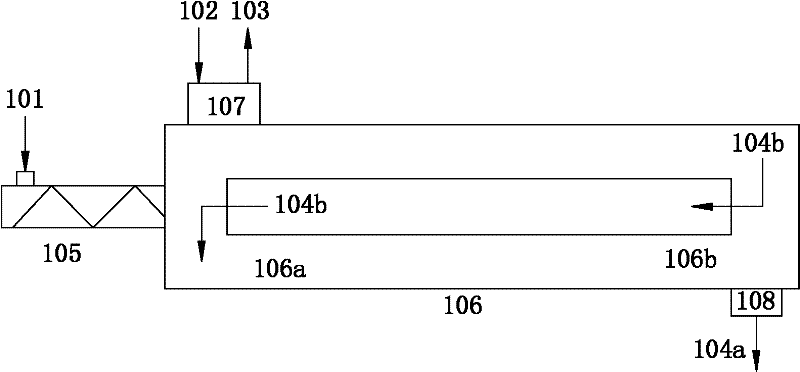

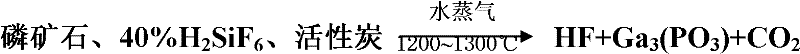

Method used

Image

Examples

Embodiment 1

[0062] Put 100kg of NaAlF 4 And 156kg of 100% concentrated sulfuric acid is added to the temperature of 260℃, slight negative pressure 10mmH 2 O reaction in the rotary reactor. The hydrogen fluoride gas produced by the reaction is pumped out of the furnace head sulfuric acid chute, and is collected, dried and purified. The mixture of sodium sulfate and aluminum sulfate generated at the end of the furnace and the incompletely reacted NaAlF 4 A part is returned to the furnace head through the internal return mechanism, and a part is discharged from the reaction furnace. Through analysis and calculation, the conversion rate of hydrogen fluoride is 96.7%, and the purity of hydrogen fluoride reaches more than 99%.

Embodiment 2

[0064] Add 94kg of NaF and 110kg of 100% concentrated sulfuric acid to a temperature of 240℃ and a slight negative pressure of 8mmH 2 O reaction in the rotary reactor. The hydrogen fluoride gas produced by the reaction is pumped out of the furnace head sulfuric acid chute, and is collected, dried and purified. Part of the sodium sulfate and incompletely reacted NaF generated at the end of the furnace is returned to the furnace head through the internal return mechanism, and part is discharged from the reaction furnace. Through analysis and calculation, the conversion rate of hydrogen fluoride is 95.8%, and the purity of hydrogen fluoride reaches more than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com