Aluminum alloy and preparation method thereof

A kind of aluminum alloy, together technology, applied in the field of aluminum alloy and its preparation, can solve the problem of insufficient strength of aluminum alloy, and achieve the effect of excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

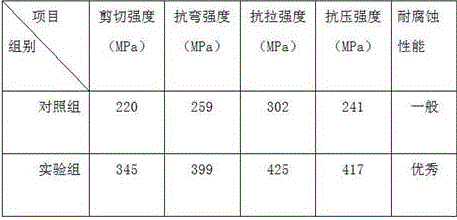

Examples

Embodiment 1

[0020] An aluminum alloy comprising the following raw materials in parts by weight: 102 parts of aluminum, 2 parts of iron, 3 parts of copper, 4 parts of titanium, 1 part of zinc, 4 parts of chromium, 2 parts of cerium, 1 part of dysprosium, and 4 parts of holmium , 1 part of thulium, 2 parts of potassium chloride, 1 part of sodium aluminum fluoride, 1 part of hexafluorobenzene, 2 parts of calcium sulfide, 1 part of sodium sulfate, 3 parts of silica fume and 7 parts of cobalt powder.

[0021] A kind of preparation method of aluminum alloy comprises the following steps:

[0022] 1) Pour 102 parts of aluminum, 2 parts of iron, 3 parts of copper, 4 parts of titanium, 1 part of zinc, 4 parts of chromium, 2 parts of cerium, 1 part of dysprosium, 4 parts of holmium and 1 part of thulium into the metal melting furnace , then heated to 800°C, and stirred after all the raw materials were completely melted to obtain liquid metal, which was set aside;

[0023] 2) Pour 2 parts of potassi...

Embodiment 2

[0026] An aluminum alloy comprising the following raw materials in parts by weight: 100 parts of aluminum, 4 parts of iron, 5 parts of copper, 6 parts of titanium, 3 parts of zinc, 6 parts of chromium, 4 parts of cerium, 3 parts of dysprosium, and 6 parts of holmium , 3 parts of thulium, 4 parts of potassium chloride, 3 parts of sodium aluminum fluoride, 3 parts of hexafluorobenzene, 4 parts of calcium sulfide, 3 parts of sodium sulfate, 5 parts of silica fume and 9 parts of cobalt powder.

[0027] A method for preparing an aluminum alloy, comprising the steps of:

[0028] 1) Pour 100 parts of aluminum, 4 parts of iron, 5 parts of copper, 6 parts of titanium, 3 parts of zinc, 6 parts of chromium, 4 parts of cerium, 3 parts of dysprosium, 6 parts of holmium and 3 parts of thulium into the metal melting furnace , then heated to 800°C, and stirred after all the raw materials were completely melted to obtain liquid metal, which was set aside;

[0029] 2) Pour 4 parts of potassium...

Embodiment 3

[0032] An aluminum alloy comprising the following raw materials in parts by weight: 101 parts of aluminum, 3 parts of iron, 4 parts of copper, 5 parts of titanium, 2 parts of zinc, 5 parts of chromium, 3 parts of cerium, 2 parts of dysprosium, and 5 parts of holmium , 2 parts of thulium, 3 parts of potassium chloride, 2 parts of sodium aluminum fluoride, 2 parts of hexafluorobenzene, 3 parts of calcium sulfide, 2 parts of sodium sulfate, 4 parts of silica fume and 8 parts of cobalt powder.

[0033] A method for preparing an aluminum alloy, comprising the steps of:

[0034] 1) Pour 101 parts of aluminum, 3 parts of iron, 4 parts of copper, 5 parts of titanium, 2 parts of zinc, 5 parts of chromium, 3 parts of cerium, 2 parts of dysprosium, 5 parts of holmium and 2 parts of thulium into the metal melting furnace , then heated to 800°C, and stirred after all the raw materials were completely melted to obtain liquid metal, which was set aside;

[0035] 2) Pour 3 parts of potassium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com