Biological Aerated Filter and Its Sewage Treatment Process

A biological aerated filter and sewage treatment technology, which is applied in the field of sewage treatment, can solve problems such as heavy maintenance workload, increased equipment cost investment, and complicated operation methods, and achieves prolonged residence time, extended backwash cycle, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Industrial painting wastewater such as automobile painting usually has high CODcr content and extremely low ammonia nitrogen content. The main pollutants are heavy metals, complexes, phosphorus and other substances. After pretreatment, the COD is usually about 1500mg / l, and after acid treatment After that, the pH value was adjusted to 3.5; after micro-electrolytic oxidation catalysis, the pH value was adjusted to 10 by adding alkali, and the flocculation and precipitation were carried out; then the pH value was adjusted to 7.5 by adding acid, and the COD was 600~750 mg at this time / l, BOD 5 100~200mg / l. The sewage treated in the above steps is used as the influent of the present invention.

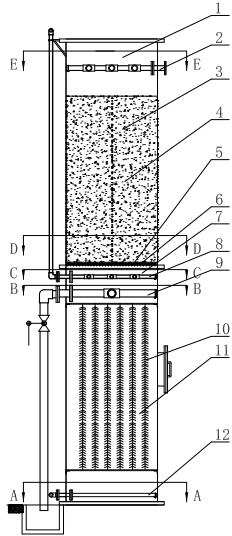

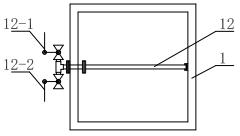

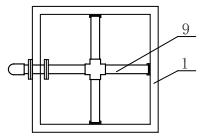

[0061] Feed water into the bottom water inlet pipe 12 of the biological aerated filter tank body 1 of the present invention, after the sewage passes through the filler layer in the anoxic zone and the filter material layer in the aerobic zone, pre-denitrification treatment is carr...

Embodiment 2

[0063] Domestic sewage usually has a high content of ammonia nitrogen, COD / BOD 5 >30%, relatively high, easy to biochemical treatment. COD is 300~400 mg / l after the pretreatment process in similar embodiment 1, BOD 5 150-200mg / l, ammonia nitrogen value ≥ 30mg / l, the domestic sewage after the above-mentioned steps is used as the influent of the present invention.

[0064] Feed water into the bottom water inlet pipe 12 of the biological aerated filter tank body 1 of the present invention, after the sewage passes through the filter material layer in the anoxic zone and the packing layer in the aerobic zone, pre-denitrification treatment occurs, and passes through the top The drain pipe 2 discharges the tank body 1; since the ammonia nitrogen content in the domestic sewage is very high, this embodiment needs to return the effluent. According to the level of ammonia nitrogen content and the specific denitrification requirements, the return flow can reach up to 300%; at the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com