Treatment methods of papermaking wastewater

A treatment method and papermaking wastewater technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem that the effluent is difficult to meet the discharge standards, and achieve high treatment control standards, The effect of high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the present invention easier to understand, specific embodiments of the present invention will be further described below.

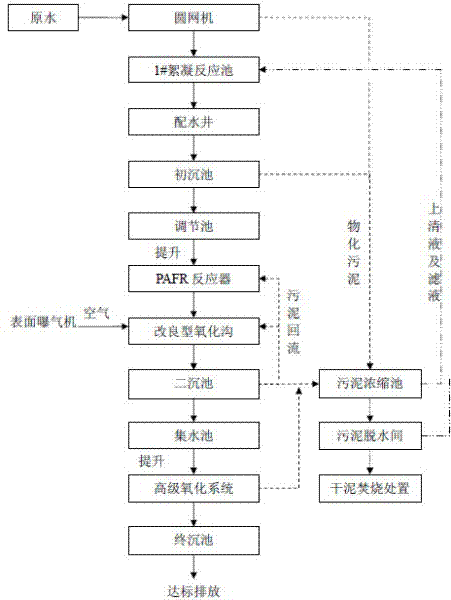

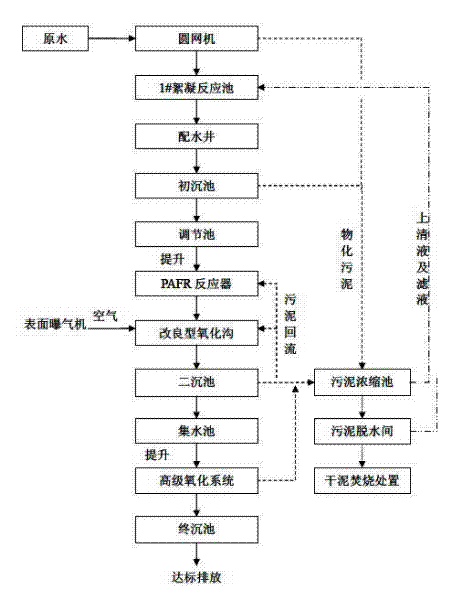

[0028] A combined treatment method for high-standard discharge of papermaking wastewater, for treating papermaking wastewater, the method includes the following steps:

[0029] (1) After pretreatment, the papermaking wastewater is subjected to physical and chemical treatment, and after the mud-water separation in the primary sedimentation tank, it flows to the regulating tank by itself;

[0030] (2) The wastewater from the adjustment tank is lifted to the PAFR reactor for hydrolysis and acidification reaction. After hydrolysis and acidification, the effluent flows into the improved oxidation ditch system by itself, and the effluent from the oxidation ditch enters the secondary sedimentation tank for mud-water separation, and the effluent flows to the sump by itself;

[0031] (3) The wastewater from the sump tank is elevated and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com