A composite of silicon nanowire-organic functional compound and its preparation method

A technology for silicon nanowires and compounds, which is applied in the field of silicon nanowire-organic functional compound complexes, can solve the problems of interaction limitation, high activity of siloxane-based compounds and difficult to control, and difficult interface performance regulation, etc., and achieves the light absorption range. extended effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

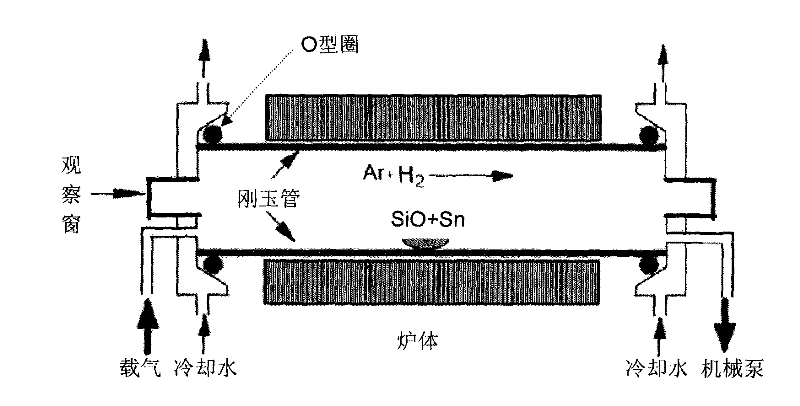

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, prepare the complex of silicon nanowire-ethanol hydroxypyrene Schiff base

[0034] (1) Synthesis of ethanol hydroxypyrene Schiff base

[0035] The reaction raw materials are Pyrene-CHO (pyrene formaldehyde) and hydroxyethylamine H 2 N-(CH 2 ) 2 -OH, the reaction equation is as follows:

[0036]

[0037] Specific synthesis method: Weigh 230 mg of Pyrene-CHO and 183 mg of ethanolamine, mix them and place them in 50 ml of ethanol solution, heat and reflux for 12 hours, collect the precipitated pale yellow precipitate by filtration, wash with water, and dry to obtain ethanol hydroxy pyrene-CHO husband base.

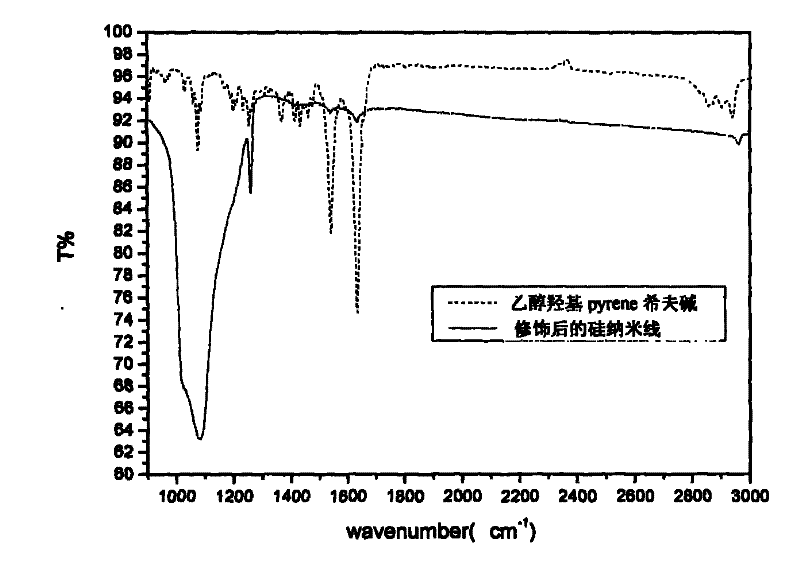

[0038] (2) Preparation of composites of silicon nanowires-ethanol hydroxypyrene Schiff base

[0039]Weigh 20 mg of silicon nanowire raw material, immerse it in a 10% HF solution for 1 hour; place the soaked silicon nanowire in a vacuum drying oven at a drying temperature of 50°C and a pressure of 1000pa drying in medium for 10 hours to obtain sil...

Embodiment 2

[0042] Embodiment 2, preparation of the complex of silicon nanowire-ethanol hydroxypyrene Schiff base

[0043] Weigh 20 mg of silicon nanowire raw material, immerse it in a 10% HF solution for 1 hour; place the soaked silicon nanowire in a vacuum drying oven at a drying temperature of 50°C and a pressure of 1000pa Medium drying treatment was carried out for 6 hours to obtain silicon nanowires after drying treatment. Add 20mg of ethanol hydroxypyrene Schiff base (prepared according to the method of Example 1) and the dried silicon nanowires into 100ml of anhydrous toluene, stir, and react at 80°C for 24 hours; After cooling and filtering, the composite of silicon nanowire-ethanol hydroxypyrene Schiff base is obtained; the composite is cleaned with toluene-ethanol system (volume ratio 1:3), dried in nitrogen environment and stored.

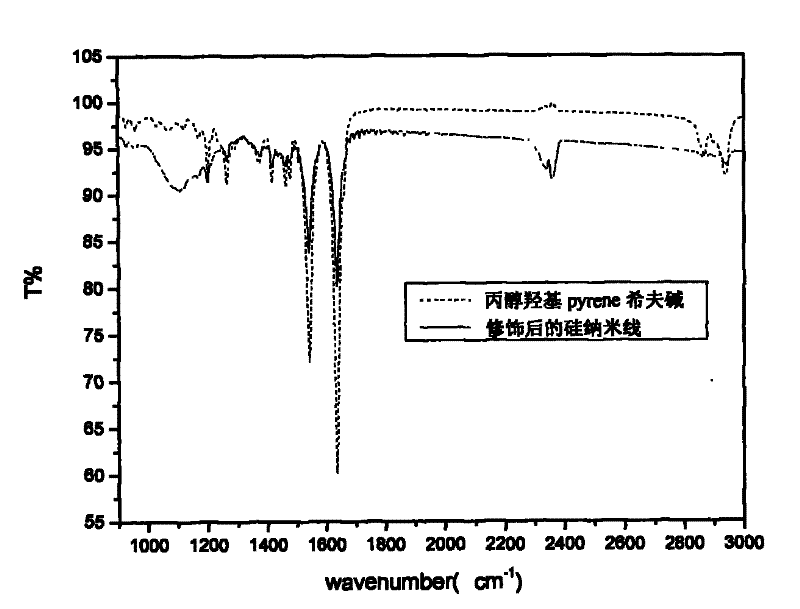

Embodiment 3

[0044] Example 3, preparation of the composite of silicon nanowire-ethanol hydroxypyrene Schiff base

[0045] Weigh 20 mg of silicon nanowire raw material, immerse it in a 10% HF solution for 1 hour; place the soaked silicon nanowire in a vacuum drying oven at a drying temperature of 10°C and a pressure of 1000pa drying in medium for 10 hours to obtain silicon nanowires after drying. Add 15mg of ethanol hydroxypyrene Schiff base (prepared according to the method of Example 1) and the dried silicon nanowires into 100ml of anhydrous toluene, stir, and react at 50°C for 20 hours; After cooling and filtering, a composite of silicon nanowire-ethanol hydroxypyrene Schiff base is obtained; the composite is cleaned with a toluene-ethanol mixed system (volume ratio 1:3), dried in a nitrogen environment and stored.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com