Solar cell photo-anode using semiconductor thin film as sensitizing agent and preparation method of solar cell photo-anode

A technology for solar cells and semiconductors, applied in the direction of photosensitive equipment, etc., can solve the problems of less adsorption of sensitizers, poor controllability, and low coverage, and achieve improved photoelectric conversion efficiency, simple and convenient preparation methods, continuous and scalable bandgap tune effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

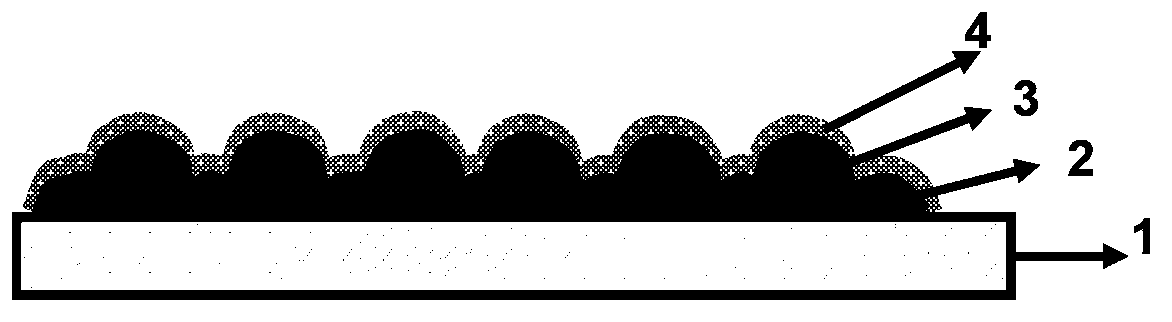

[0035] Wide bandgap semiconductor chooses TiO 2 Porous membrane composed of nanoparticles, TiO 2 The particle size is about 20nm and the thickness is about 5μm. Use dimethyl cadmium, trimethylsilthione, and trimethylsilylselenane as raw materials, high argon as carrier gas, carrier gas flow rate 100 sccm, reaction temperature 150 ° C, chamber pressure 10 -1 toor, cation and anion sources alternately enter the main chamber, and the pulse time of a single source is 0.05s. After atomic layer deposition (ALD) grows CdS / CdSe with different thicknesses, the morphology of nanotubes basically does not change, which is consistent with atomic layer deposition (ALD). Growth (conformal deposition) characteristics. using atomic layer deposition (ALD) on TiO 2 200 cycles of CdS film and 200 cycles of CdS / 200 cycles of CdSe were grown on the porous membrane, and CdS sensitized cells and CdS / CdSe co-sensitized cells were prepared respectively. The data and results are shown in the table. ...

Embodiment 2

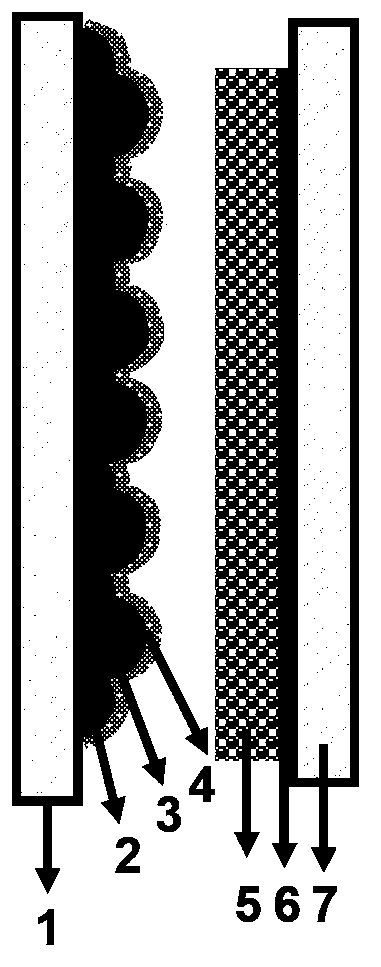

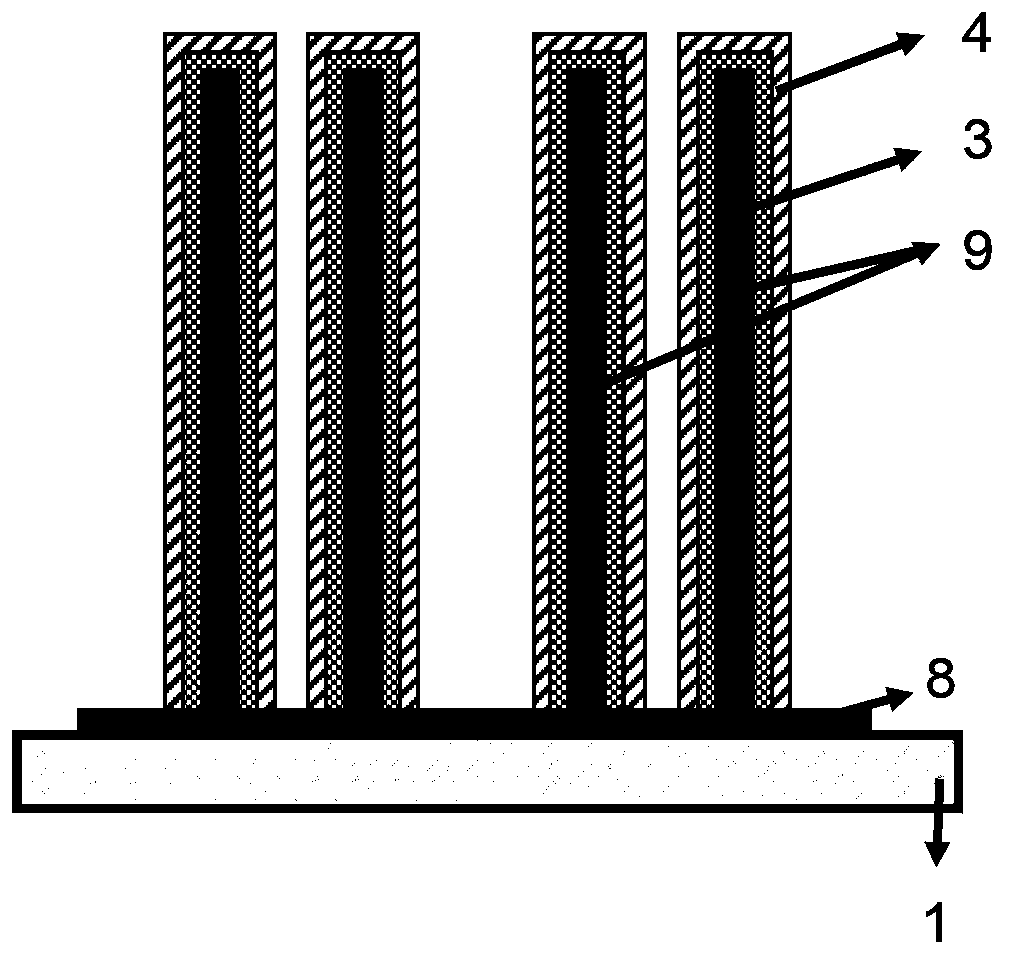

[0038] The difference from Example 1 is that the wide bandgap semiconductor uses TiO 2 A porous membrane composed of nanotube arrays, the outer diameter of nanotubes is about 110nm, the inner diameter is about 80nm, and the tube length is about 15μm. Use dimethyl cadmium, trimethylsilthione, and trimethylsilylselenane as raw materials, high argon as carrier gas, carrier gas flow rate 100 sccm, reaction temperature 150 ° C, chamber pressure 10 -1 toor, cation and anion sources alternately enter the main chamber, and the pulse time of a single source is 0.05s. After atomic layer deposition (ALD) grows CdS / CdSe with different thicknesses, the morphology of nanotubes basically does not change, which is consistent with atomic layer deposition (ALD). Growth (conformal deposition) characteristics.

[0039] Figure 5 a: Scanning electron microscope (SEM) image of the top of the nanotube before atomic layer deposition (ALD) growth of CdS / CdSe

[0040] Figure 5 b: Scanning electron...

Embodiment 3

[0044] The difference from Example 1 is that the wide bandgap semiconductor uses TiO 2 A porous membrane composed of nanotube arrays, the outer diameter of nanotubes is about 110nm, the inner diameter is about 80nm, and the tube length is about 15μm. Use dimethyl cadmium and trimethylsilthione as raw materials, high argon as carrier gas, carrier gas flow rate 100 sccm, reaction temperature 150 ° C, chamber pressure 10 -1 toor, cation and anion sources alternately enter the main chamber, and the pulse time of a single source is 0.05s. After atomic layer deposition (ALD) grows CdS with different thicknesses, the morphology of nanotubes basically does not change, which is consistent with atomic layer deposition (ALD) conformal growth ( conformal deposition) features. using atomic layer deposition (ALD) on TiO 2 The sensitized battery is assembled by depositing different cycles of CdS films on the nanotubes. The short-circuit current increases with the increase of the amount of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com