Method for adjusting band gap of vanadium dioxide film

A technology of vanadium dioxide and thin film, applied in vanadium oxide, coating and other directions, can solve the problems of unsuitability for large-scale production, high cost, complicated control process, etc., and achieve the effect of improving visible light transmittance and solar energy regulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Preparation of Vanadium Dioxide Film with Adjustable Band Gap

[0026] The present invention uses alkaline reagents to treat tetravalent vanadium ions and doped ion aqueous solution to obtain a precursor treatment process of suspension. In the precursor treatment step, an alkaline reagent can be used to titrate the tetravalent vanadium ion and the doped ion aqueous solution until a suspension is formed. The pH of the end point of the titration can be 2-12, preferably 5-10, and more preferably 6-8.

[0027] In the present invention, the tetravalent vanadium ion aqueous solution can be prepared by dissolving soluble vanadium raw materials in water. Commonly used soluble vanadium raw materials can be trivalent, tetravalent or pentavalent vanadium salts and / or their hydrates, preferably tetravalent soluble vanadium salts and their hydrates, such as vanadium oxysulfate (VOSO 4 ), vanadium oxychloride (VOCl 2 ) And vanadyl oxalate anhydrate (VOC 2 O 4 ·5H 2 O). It should be under...

Embodiment 1

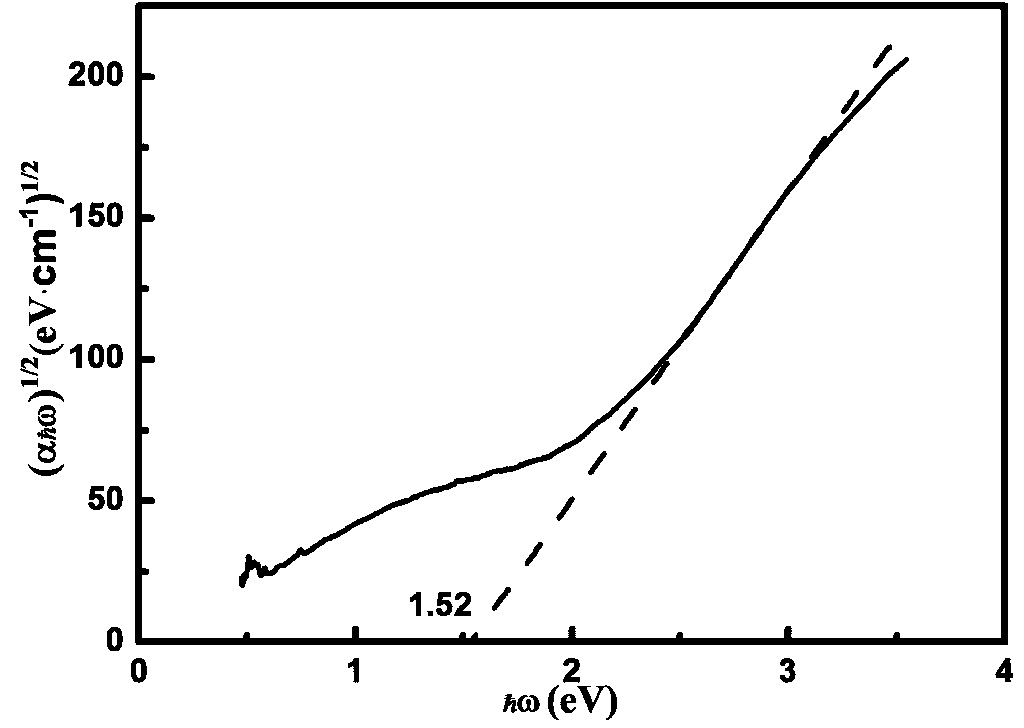

[0047] 10g VOSO 4 Dissolve in 50ml deionized water, titrate with 1mol / L NaOH solution, and keep stirring. After the titration is complete, put the suspension into a 50ml hydrothermal kettle containing 45ml deionized water, and react hydrothermally at 240℃ for 96 hours , Centrifugal drying to obtain vanadium dioxide powder. The XRD spectrum shows that the crystal phase is pure M phase. The DSC curve shows that vanadium dioxide powder has phase transition properties, and the phase transition temperature is 67°C. The ultraviolet-visible absorption spectrum shows that its optical band gap is 1.53 eV and the intrinsic band gap is 0.7 eV.

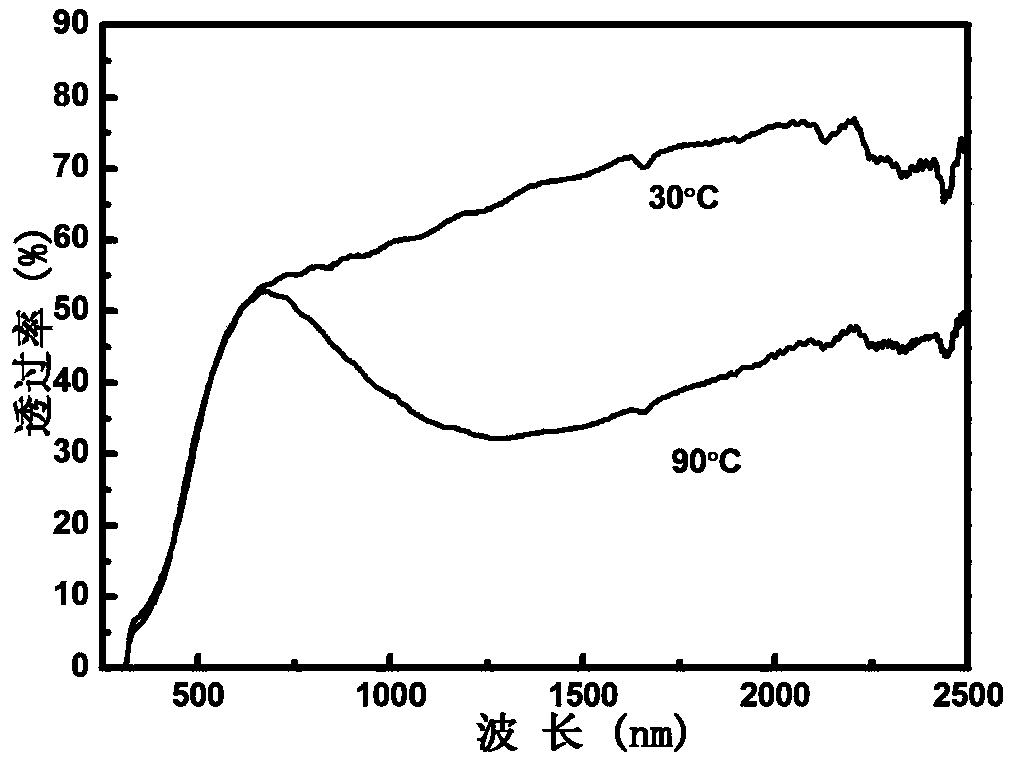

[0048] Grind 1g of the above-prepared VO2 powder and put it into a small beaker containing 20ml of water with constant stirring, add 0.5g of polyvinylpyrrolidone K-30, stir for 30 minutes and then ultrasonic for 60 minutes to prepare a dispersion. The obtained dispersion is coated on a glass substrate by a spin coating method, and then dried at ro...

Embodiment 2

[0050] 5g VOCl 2 And 0.005g MgCl 2 Dissolve in 50ml deionized water, use 0.5mol / L NH 3 ·H 2 The O solution is titrated with constant stirring. After the titration is completed, the suspension is put into a 50ml hydrothermal kettle containing 45ml of deionized water, reacted hydrothermally at 290°C for 18 hours, centrifuged and dried to obtain magnesium-doped vanadium dioxide powder , Its chemical formula is Mg 0.007 V 0.993 O 2 . The phase of magnesium doped vanadium dioxide powder is M phase, and the phase transition temperature is 64°C. The optical band gap of 0.7% magnesium doped vanadium dioxide powder is 1.60 eV, and the intrinsic band gap is 0.72 eV.

[0051] 1g Mg 0.007 V 0.993 O 2 The powder repeats the experiment in Example 1 to prepare a magnesium-doped vanadium dioxide film. Calculating with spectral data, it is found that the integrated visible light transmittance before and after the phase change of the film is 52.4% and 49.7%, and the solar control rate is 11.2%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Variable temperature | aaaaa | aaaaa |

| Optical bandgap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com