Preparation method of taste-masking slow-release allicin composite microcapsules

An allicin and slow-release technology, which is applied in the field of microcapsule preparation, can solve the problems of intramuscular injection pain, short biological half-life, and inconvenience of intravenous injection, and achieve the effects of improving sustained-release performance, encapsulation efficiency, and drug loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

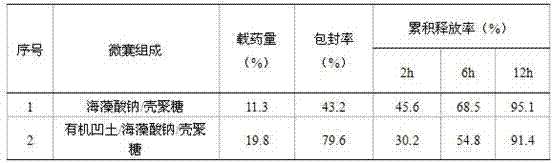

Examples

Embodiment 1

[0017] Suspend 2 g of attapulgite in 100 mL of 0.5 % (w / v) CTAB solution, stir at 70 °C for 8 h, then filter and wash with suction, no bromide ions can be detected in the washing liquid, dry at 105 °C, and grind for 200 mesh sieve to obtain organic attapulgite; dissolve 1.0 g of allicin in 8 mL of absolute ethanol, add 2.0 g of Sodium alginate solution 100 mL was dispersed at room temperature for 15 min at high speed to obtain a uniform suspension; the suspension was dropped into 2% (w / v) calcium chloride solution with a constant flow pump at a flow rate of 2.2 rpm, Cross-link for 30 min to obtain gel microcapsules, filter with suction, wash the calcium ions on the surface of the gel microcapsules, transfer to 1% (w / v) chitosan solution with a molecular weight of 600,000 for coating for 2 h, filter , washed to obtain uniform and smooth spherical microcapsules, vacuum-dried to constant weight at 40°C to obtain allicin composite microcapsules.

Embodiment 2

[0019] Suspend 1 g of attapulgite in 100 mL of 0.1 % (w / v) CTAB solution, stir at 60 °C for 12 h, filter and wash with suction, no bromide ions can be detected in the washing solution, dry at 105 °C, and grind for 200 Mesh sieve to obtain organic attapulgite; dissolve 1.0 g of allicin in 5 mL of absolute ethanol, add 1.0 g of organic attapulgite in a 100 mL round-bottomed flask, mix well, evaporate to dryness, add 2% (w / v) seaweed Sodium chloride solution 25 mL, high-speed dispersion at room temperature for 15 min to obtain a uniform suspension; use a constant flow pump to drop the suspension into 2% (w / v) calcium chloride solution at a flow rate of 2.2 rpm, cross-linked 10 min, get the gel microcapsules, filter with suction, wash the calcium ions on the surface of the gel microcapsules, transfer to a 2% (v / v) chitosan solution with a molecular weight of 500,000, cover the film for 1 h, filter, and wash , to obtain uniform and smooth spherical microcapsules, vacuum-dry at 40 ℃...

Embodiment 3

[0021] Suspend 6 g of attapulgite in 200 mL of 1.0% (w / v) CTAB solution, stir at 80°C for 6 h, filter and wash with suction, no bromide ions can be detected in the washing solution, dry at 105°C, and grind for 200 Mesh sieve to obtain organic attapulgite; dissolve 1.0 g of allicin in 10 mL of absolute ethanol, add 4.0 g of organic attapulgite in a round bottom flask, mix well, evaporate to dryness, add 2 % (w / v) alginic acid Disperse 800 mL of sodium solution at room temperature for 15 minutes at high speed to obtain a uniform suspension; drop the suspension into 2% (w / v) calcium chloride solution with a constant flow pump at a flow rate of 2.2 rpm, and crosslink 60 min, get the gel microcapsules, suction filter, wash the calcium ions on the surface of the gel microcapsules, transfer to a 0.5% (v / v) chitosan solution with a molecular weight of 700,000 for coating for 3 h, filter, wash, Uniform and smooth spherical microcapsules were obtained, and vacuum-dried at 40 °C to const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com