Preparation method of chitosan/hydroxyapatite three-dimensional porous scaffold material

A hydroxyapatite, three-dimensional porous technology, applied in the field of materials, can solve the problems of irregular pores of the scaffold material, exerting a large extrusion force, fragmentation of the porogen, etc., and achieves good effect, convenient operation and simple method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Dissolving chitosan and hydroxyapatite

[0035] Dissolve 1g chitosan (deacetylation degree is 80%~95%), 0.1g hydroxyapatite in the acetic acid aqueous solution of 100mL 20g / L, stir for 6 hours, centrifuge to remove air bubbles, obtain chitosan and hydroxyapatite stone mixture.

[0036] 2. Preparation of chitosan / hydroxyapatite three-dimensional porous composite scaffold material

[0037] SiO 2 Microspheres are porogens, SiO with a particle size of 100-150 μm 2 Add the microspheres into a 20 mL syringe with a needle, squeeze and tamp the SiO with a pestle 2 Microspheres until their position in the syringe does not change, SiO 2 The amount of microspheres added is 0.25 of the volume of the syringe, and then the mixed solution of chitosan and hydroxyapatite is added to the syringe, and the added amount of the mixed solution is the same as that of SiO 2 The volume of the microspheres is the same, pushing the plunger handle of the syringe makes the mixed solution flo...

Embodiment 2

[0044] In the preparation chitosan / hydroxyapatite mixed solution step 1 of embodiment 1, 1g chitosan (deacetylation degree is 80%~95%), 0.2g hydroxyapatite are dissolved in 100mL 20g / L in aqueous acetic acid solution, stirred for 6 hours, and centrifuged to remove air bubbles. The other steps were the same as in Example 1, and a chitosan / hydroxyapatite three-dimensional porous scaffold material was prepared.

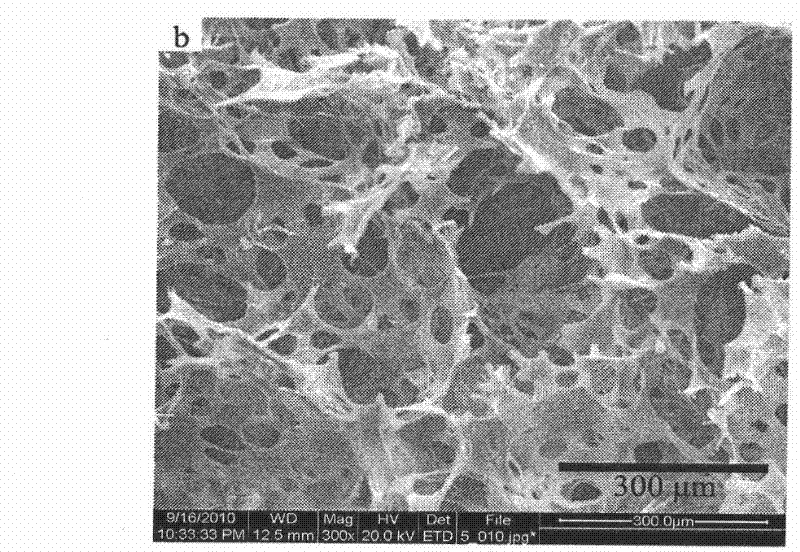

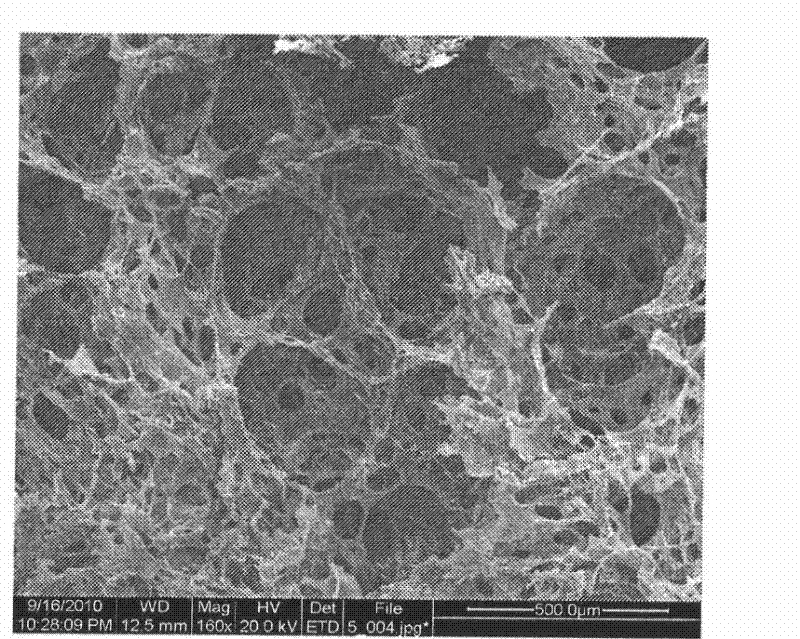

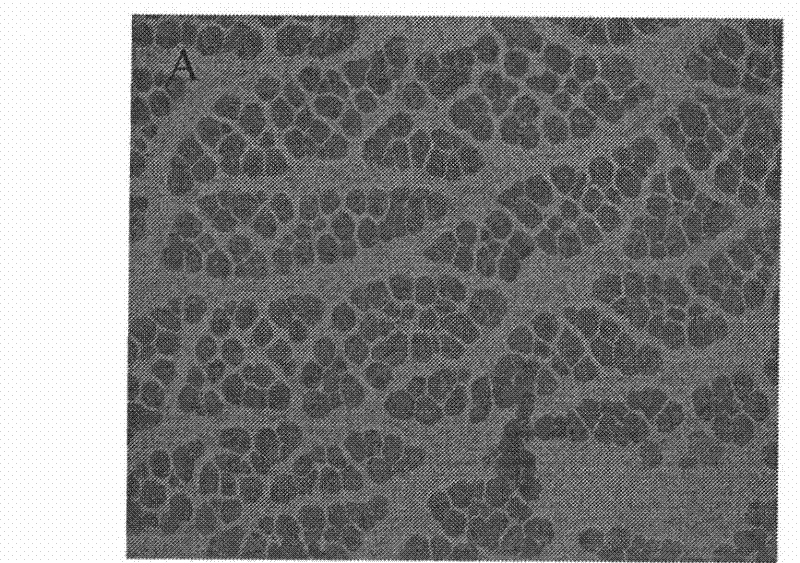

[0045] According to the method of test 1, the morphology characterization, porosity and compressive strength test were carried out. The experimental results showed that the pores of the composite porous scaffold were open, the connectivity between the pores was good, and the average pore diameter was 117 μm (see figure 2 ), the porosity is 91.97%, and the compressive strength is 818kPa.

Embodiment 3

[0047] In step 1 of dissolving chitosan and hydroxyapatite in the present embodiment, 1 g of chitosan (the degree of deacetylation is 80% to 95%) and 0.05 g of hydroxyapatite are dissolved in 100 mL of 20 g / L acetic acid aqueous solution , stirred for 4 hours, and centrifuged to remove air bubbles. The other steps were the same as in Example 1, and a chitosan / hydroxyapatite three-dimensional porous scaffold material was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com