Scr denitrification process and device for high dust flue gas

A technology of a dust removal device and an SCR reactor, applied in the field of flue gas purification, can solve the problems of large losses, increase operating costs, shorten the service life of catalysts, etc., and achieve the effect of reducing the probability of blockage, prolonging the life of catalysts, and reducing the amount of catalysts used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

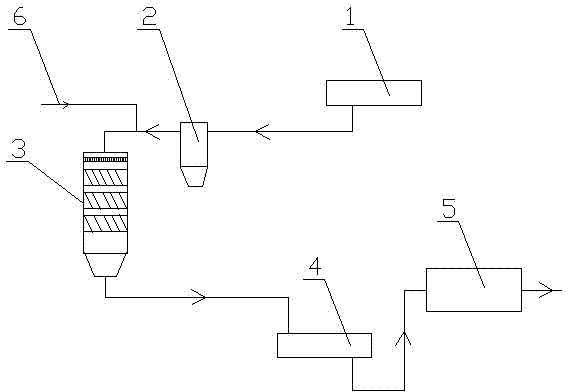

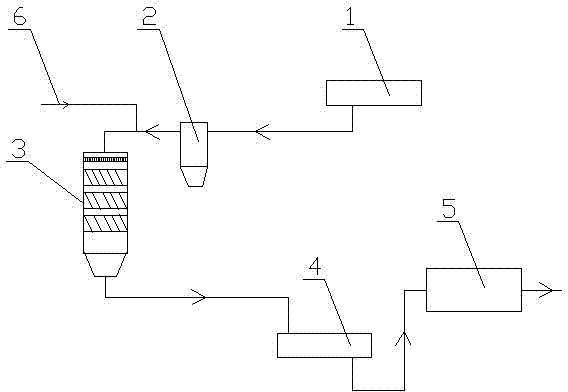

[0024] figure 1 It is a process flow diagram of the present invention, as shown in the figure, the SCR denitration device for high dust flue gas of the present invention includes a boiler economizer 1, a dust removal device 2 and an SCR reactor 3, and the boiler economizer 1 The flue gas outlet communicates with the inlet flue of the SCR reactor 3 through the dust removal device 2 .

[0025] In the present embodiment, the dust removal device 2 is a gravity dust collector; although common dust removal devices such as centrifugal dust removal (such as cyclone separator) or filter dust removal can also achieve the effect of the present invention, but with these dust removal devices, the flue gas The pressure loss is very large, and the wear is serious when dealing with high-concentration or abrasive dust; while using a gravity dust collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com