A ring-shaped production line prefabricated windproof open hole component technology

A production line and component technology, which is applied in the field of prefabricated windproof open hole components in the circular production line, can solve the problems of large influence of human operation factors, many lifting machinery and equipment, and large layout area of the workshop, so as to achieve low labor intensity for workers and low component cost. The effect of high quality reliability and overall investment reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

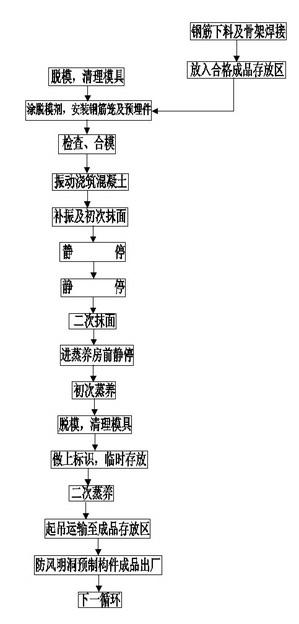

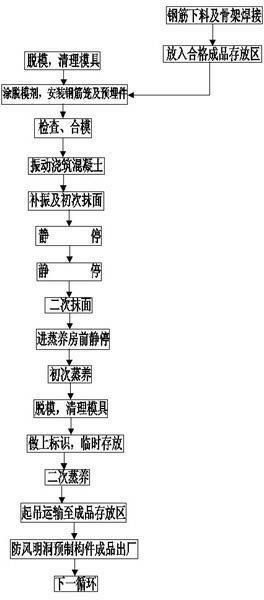

Method used

Image

Examples

Embodiment

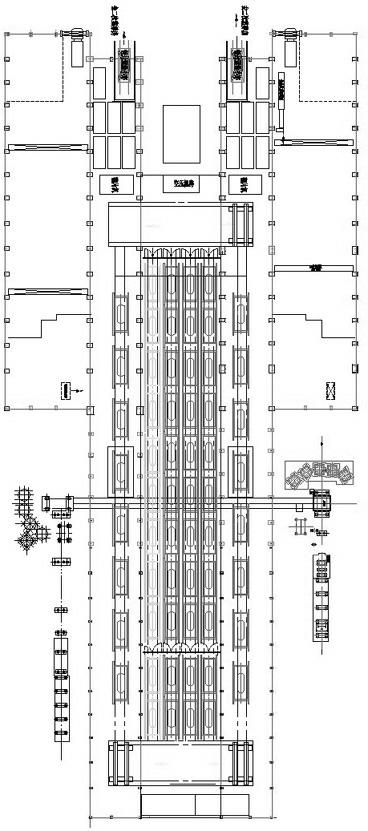

[0039] After the mold trolley of the HSL48 / 60MD segment flow production line is driven out of the steaming room, the trolley is moved to the pouring line through the ejection tunnel, and after the demoulding station stops completely, the workers at the demoulding station remove the The demoulding operation of the components is carried out in sequence, and then the components are lifted from the mold and placed in the designated temporary storage area for the components. After reaching the strength, it will be lifted and transported to the storage area for storage. After the component is demolded, the workers at the station check the mold cleaning condition, use special tools to evenly spray the mold release agent on the inner surface of the mold, then hoist and place the reinforcement cage and embedded parts, and check and close the upper cover of the mold. Then the trolley brings the mold into the concrete pouring vibration room, and the operator connects the power device req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com