Preparation method of spherical nickel hydroxide used as battery cathode material

A technology of spherical nickel hydroxide and battery positive electrode, which is applied in the direction of nickel oxide/nickel hydroxide, battery electrodes, circuits, etc., can solve the problems of very strict control of reaction conditions, and achieve uniform particle size distribution of products, good thermal stability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 4.71g of nickel chloride and add it into a round-bottomed flask filled with 50mL of 1H-1,2,4-triazoleacetic acid ionic liquid, add 0.4g of sodium dodecylsulfonate at the same time, stir to make it dissolve in the ionic liquid Under the condition of stirring, add dropwise the solution formed by 0.8g sodium hydroxide and 4mL water, heat to 100°C for 12h; after cooling, separate, wash and dry the precipitate to obtain spherical nickel hydroxide.

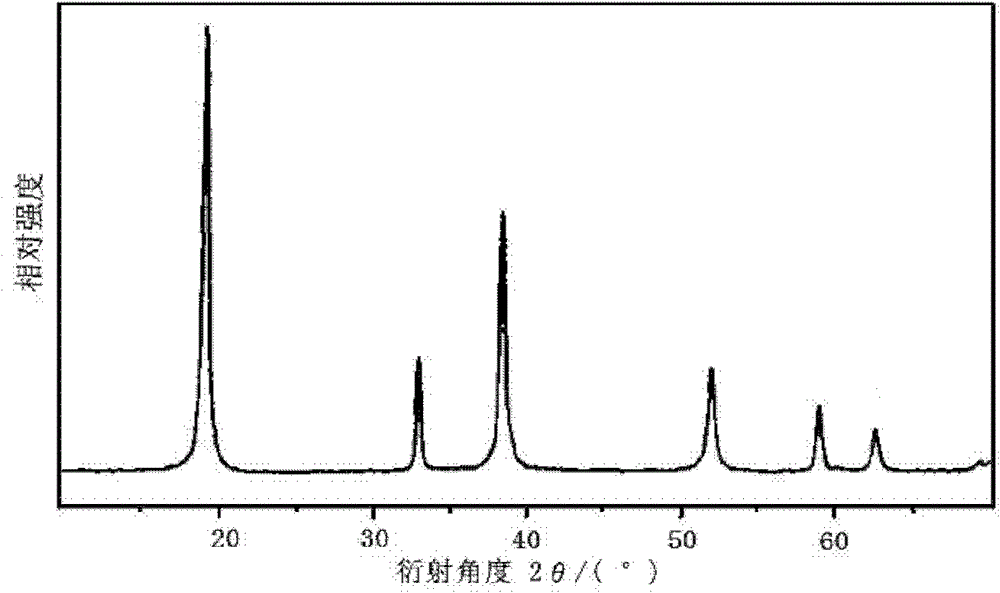

[0028] According to the XRD test of the spherical nickel hydroxide sample prepared according to Example 1, no other miscellaneous phase diffraction peaks appear, which shows that the prepared sample is good in crystallinity and β crystal form Ni(OH) with complete crystal structure. 2 .

Embodiment 2

[0030] Weigh 4.71g of nickel chloride and add it into a round bottom flask filled with 50mL of 11H-1,2,4-triazoleacetic acid ionic liquid, add 0.4g of sodium dodecylsulfonate at the same time, stir to make it dissolve in the ionic liquid Under the condition of stirring, add dropwise the solution formed by 1.12g potassium hydroxide and 4mL water, heat to 50°C for 20h; after cooling, separate, wash and dry the precipitate to obtain spherical nickel hydroxide.

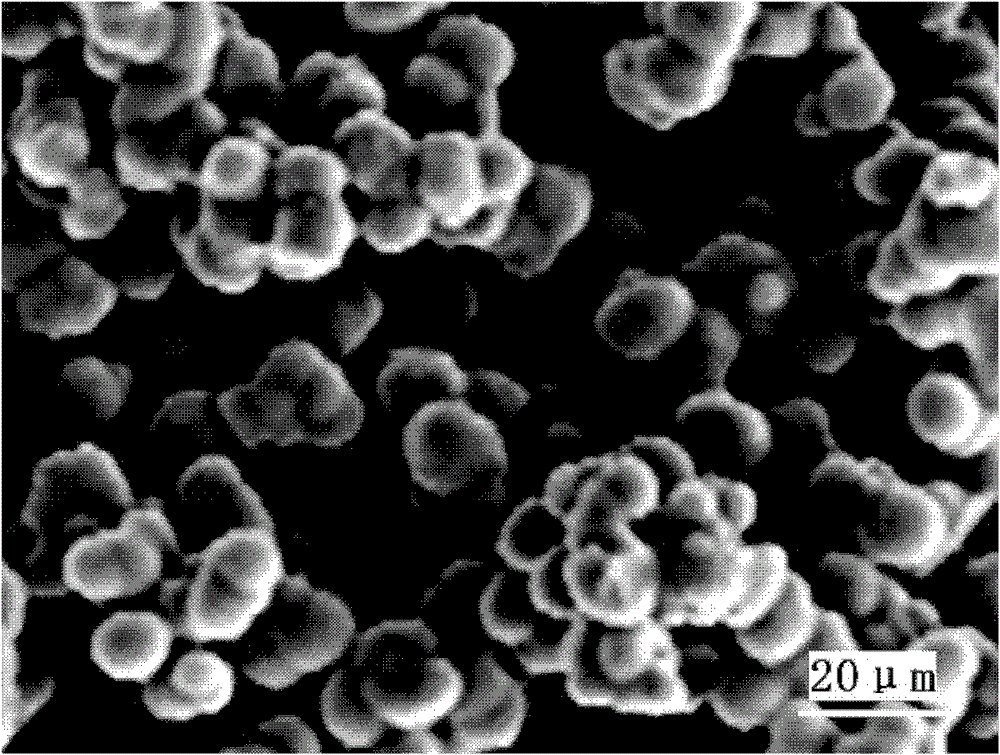

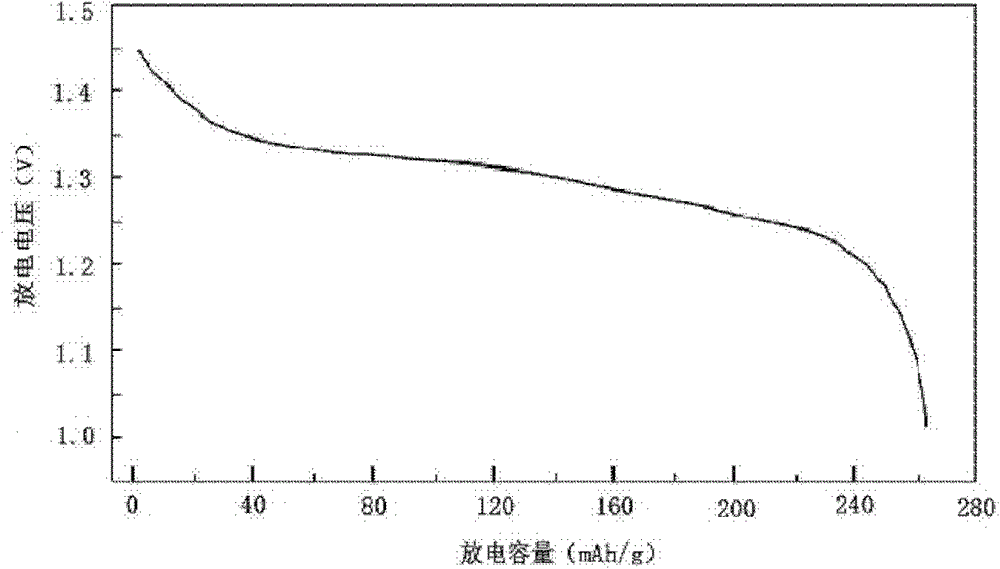

[0031] The spherical nickel hydroxide sample prepared according to Example 2 shows that it is spherical and has uniform particles through SEM testing; through electrochemical performance testing, its initial discharge capacity reaches 262.4mAh / g, and there is a relatively flat discharge platform, which shows that the prepared sample Has good electrochemical performance.

Embodiment 3

[0033] Weigh 2.5g of nickel acetate and add it to a round-bottomed flask filled with 50mL of 1H-1,2,4-triazoleacetic acid ionic liquid, and add 0.25g of sodium dodecylbenzenesulfonate at the same time, stir to make it dissolve in the ionic liquid Disperse evenly in the medium; under the condition of stirring, add dropwise the solution formed by 3.4g sodium hydroxide and 3.4mL water, heat to 220°C for 1.5h; after cooling, the precipitates are separated, washed and dried in sequence to obtain spherical nickel hydroxide .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com