A micro-arc oxidation treatment method and device

A technology of micro-arc oxidation and treatment method, applied in anodizing and other directions, can solve the problems of poor wear resistance and corrosion resistance, equipment power limitation, and high processing energy consumption, saving energy, reducing unit area, and reducing unit area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

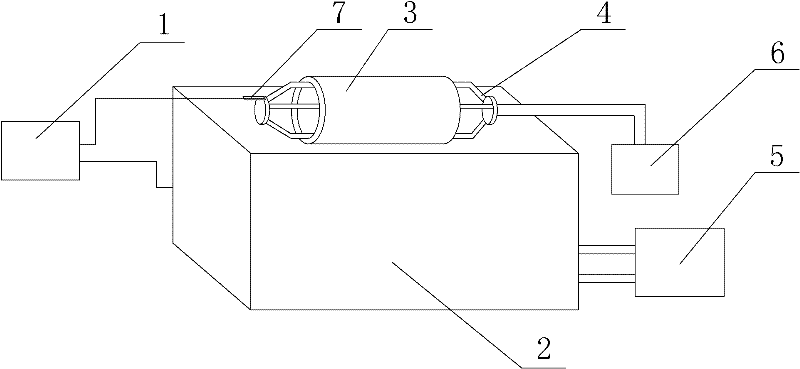

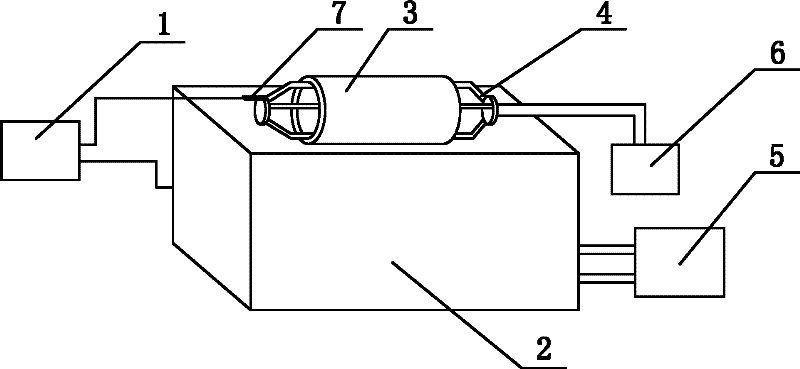

[0031] like figure 1 A kind of micro-arc oxidation processing device shown, comprises micro-arc oxidation power supply 1, electrolytic tank 2 and the stainless steel plate that is arranged on the inner wall of electrolytic tank 2 as cathode and is connected with micro-arc oxidation power supply 1 negative pole, is characterized in that, also includes The tooling 4 used to support the rotary workpiece 3 and place it suspended above the electrolytic tank 2 and the circulating cooling system 5 connected to the electrolytic tank 2 through pipes, the speed regulating motor 6 is connected to the tooling 4 and drives the rotary workpiece through the tooling 4 3 Rotate at a constant speed.

[0032] A micro-arc oxidation treatment device described in this embodiment also includes a conductive slip ring 7 connected to the positive pole of the micro-arc oxidation power supply 1, the conductive slip ring 7 is in contact with the tooling 4 and conducts electricity to the rotary workpiece 3...

Embodiment 2

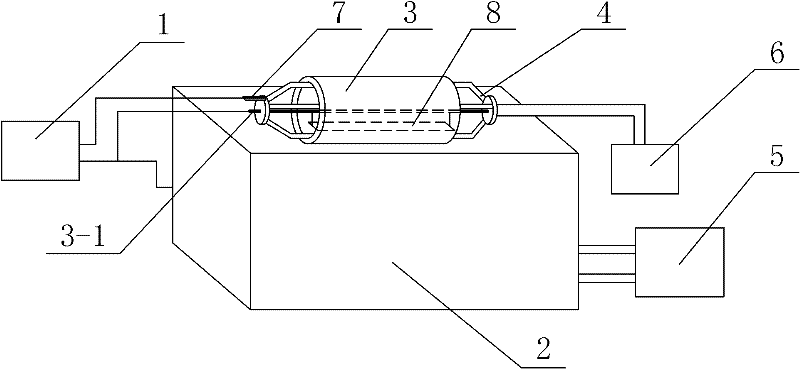

[0034] like figure 2 A kind of micro-arc oxidation processing device shown, comprises micro-arc oxidation power supply 1, electrolytic tank 2 and the stainless steel plate that is arranged on the inner wall of electrolytic tank 2 as cathode and is connected with micro-arc oxidation power supply 1 negative pole, is characterized in that, also includes The tooling 4 used to support the rotary workpiece 3 and place it suspended above the electrolytic tank 2 and the circulating cooling system 5 connected to the electrolytic tank 2 through pipes, the speed regulating motor 6 is connected to the tooling 4 and drives the rotary workpiece through the tooling 4 3 Rotate at a constant speed.

[0035] A micro-arc oxidation treatment device described in this embodiment also includes a conductive slip ring 7 connected to the positive pole of the micro-arc oxidation power supply 1, the conductive slip ring 7 is in contact with the tooling 4 and conducts electricity to the rotary workpiece ...

Embodiment 3

[0038] Step 1, using the micro-arc oxidation treatment device of Embodiment 1 to manufacture the tooling 4 for supporting the rotary workpiece 3, the rotary workpiece 3 is an aluminum workpiece;

[0039] Step 2. Select an electrolyte suitable for aluminum workpieces. The concentration of each component in the electrolyte is: sodium hexametaphosphate 12g / L-15g / L, sodium silicate 8g / L-10g / L, sodium molybdate 11g / L L ~ 13g / L, sodium carbonate 7g / L ~ 9g / L, the solvent is deionized water, and the electrolyte is added to the electrolytic cell 2;

[0040] Step 3, use the tooling 4 to support the rotary workpiece 3 above the electrolytic tank 2, and keep the partial area of the rotary workpiece 3 immersed in the electrolyte in the electrolytic tank 2;

[0041] Step 4: Connect the tooling 4 to the speed-regulating motor 6, turn on the speed-regulating motor 6, and drive the rotary workpiece 3 to rotate at a constant speed of 2 r / min through the tooling 4;

[0042] Step 5, the circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com