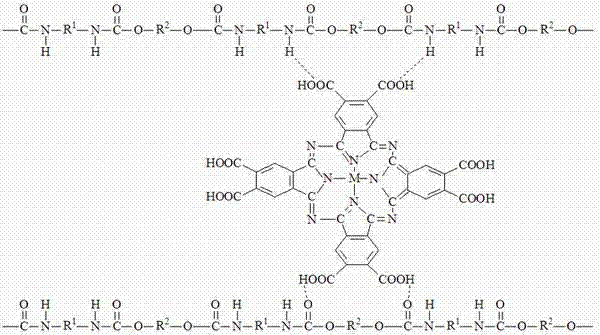

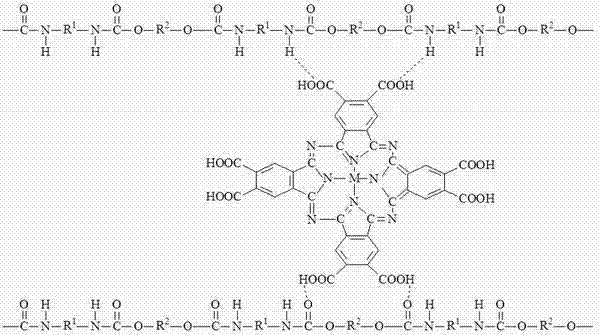

Method for producing polyurethane elastic fiber containing octacarboxyl metal phthalocyanine

A technology of polyurethane elasticity and metal phthalocyanine, which is applied in the manufacture of rayon, fiber chemical characteristics, single-component synthetic polymer rayon, etc., can solve the problems of deodorization and heat resistance of elastic fibers that have not been seen yet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

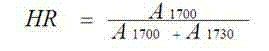

Method used

Image

Examples

Embodiment 1

[0021] Step 1 Preparation of iron octacarboxyphthalocyanine: Take 20g of pyromellitic anhydride, 104g of urea, 51g of FeCl3 (6H2O), 0.8g of catalyst ammonium molybdate, mix them and grind them in a ball mill to grind them finely and mix them evenly. Heat the medium-range power of the microwave oven (the specific value is between 500w-800w) for 10 minutes, and the obtained solids are washed twice with deionized water, acetone, and 6mol / L hydrochloric acid respectively, filtered with suction, and dried. Hydrolyze the product with 10% KOH solution at 90°C until no ammonia gas is generated, dilute it with deionized water to a specific concentration of 2L, filter with suction, and adjust the pH value of the filtrate to 6mol / L hydrochloric acid 2. Stand still, and after all the precipitates are separated out, use a sand core funnel to filter, wash with methanol for 3 times, and dry in a vacuum oven to obtain octacarboxyphthalocyanine iron.

[0022] Step 2 is equipped with a solution...

Embodiment 2

[0026] Polyurethane elastic fibers were prepared according to the same method described in Example 1, except that the content of octacarboxyphthalocyanine iron in the fibers was 5.0%.

Embodiment 3

[0028] Polyurethane elastic fibers were prepared according to the same method described in Example 1, except that the content of octacarboxyphthalocyanine iron in the fibers was 10.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com