Simple and rapid mechanical degumming production equipment and technology of ramie

A technology of production equipment and production process, applied in the field of simple and rapid mechanical degumming production equipment for ramie, can solve the problems of large consumption of electric coal, long cycle, large equipment investment, etc. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

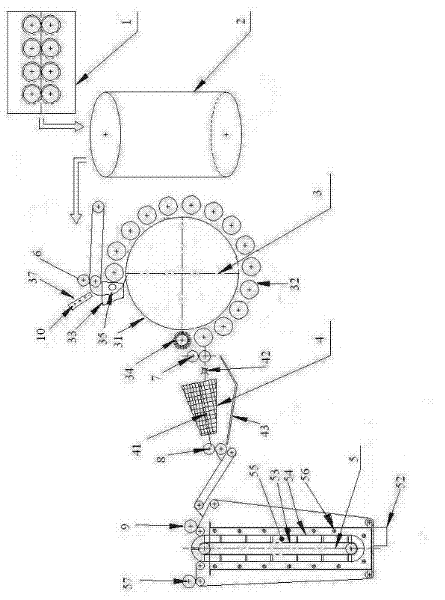

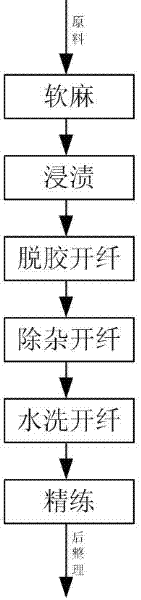

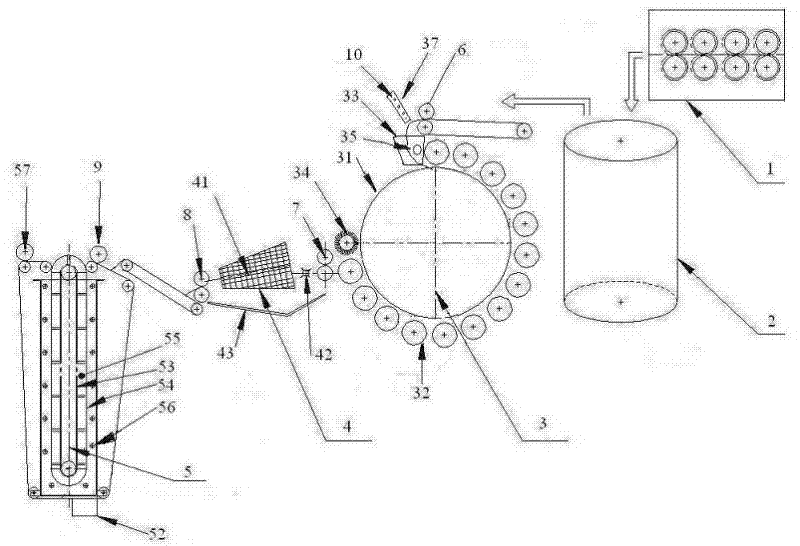

[0030] Such as figure 1 The shown simple and fast mechanical degumming production equipment for ramie is mainly composed of a softening machine 1, an impregnating device 2, a degumming opening machine 3, an impurity removing machine 4 and a washing opening machine 5 arranged in sequence; in order to realize the ramie raw material Automatic transmission, the outlet of the softening machine 1 of the present invention is arranged above the dipping device 2, and the ramie raw material automatically enters the dipping device 2 after being mechanically rubbed by the softening machine 1 to remove some impurities; A feeding roller 6 is arranged between the fiber opening machines 3, and the raw material transmission between the impregnating device 2 and the degumming fiber opening machine 3 is realized through the pulling effect of the feeding rollers 6; A transfer roller 7 is arranged between them, and the automatic transmission of raw materials between the degumming fiber opening mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com