A kind of preparation method of nickel-lanthanum bimetallic catalyst for oil hydrogenation

A bimetallic catalyst, oil hydrogenation technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of insufficient activity, no quality and price advantages, Problems such as large consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

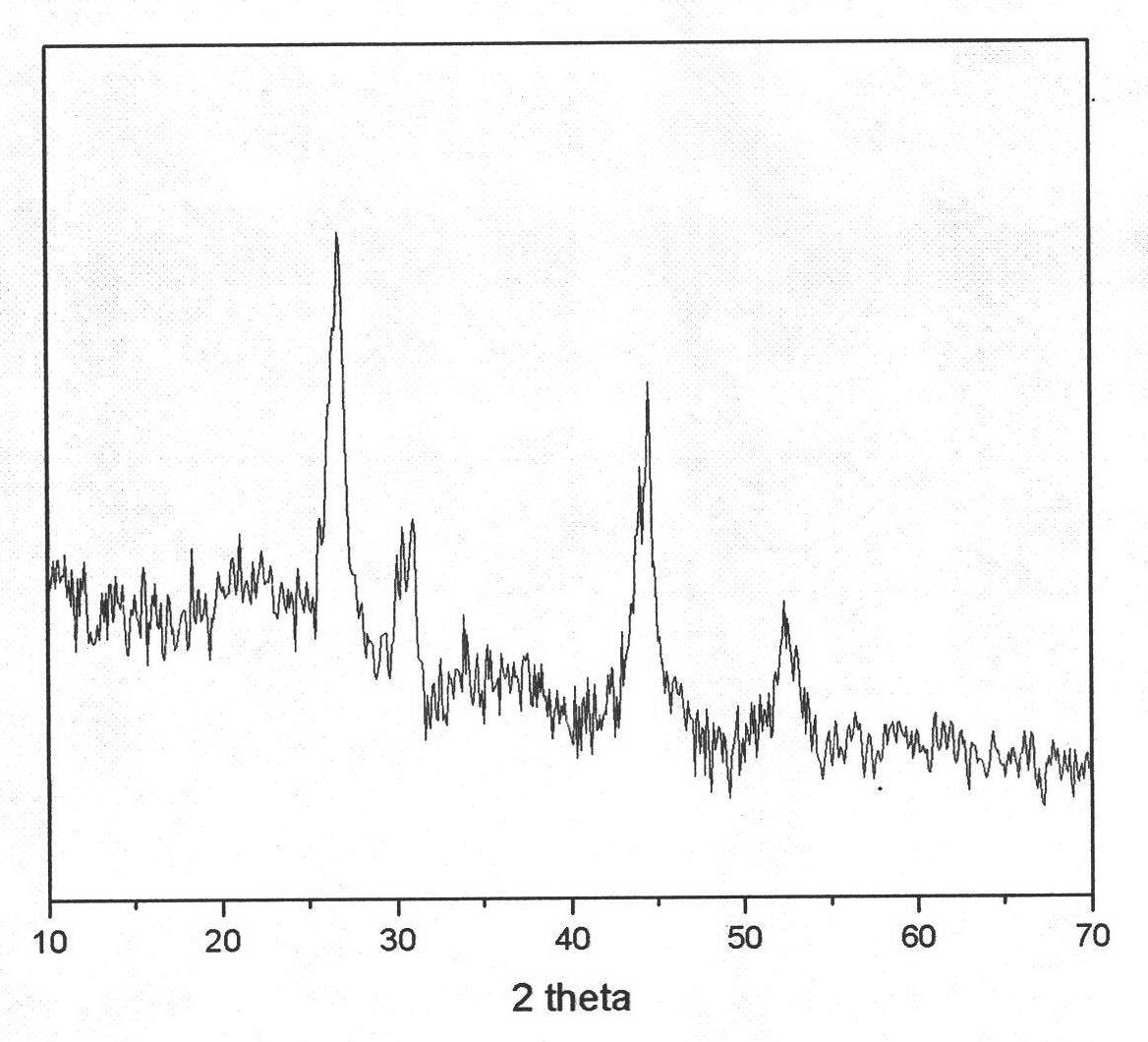

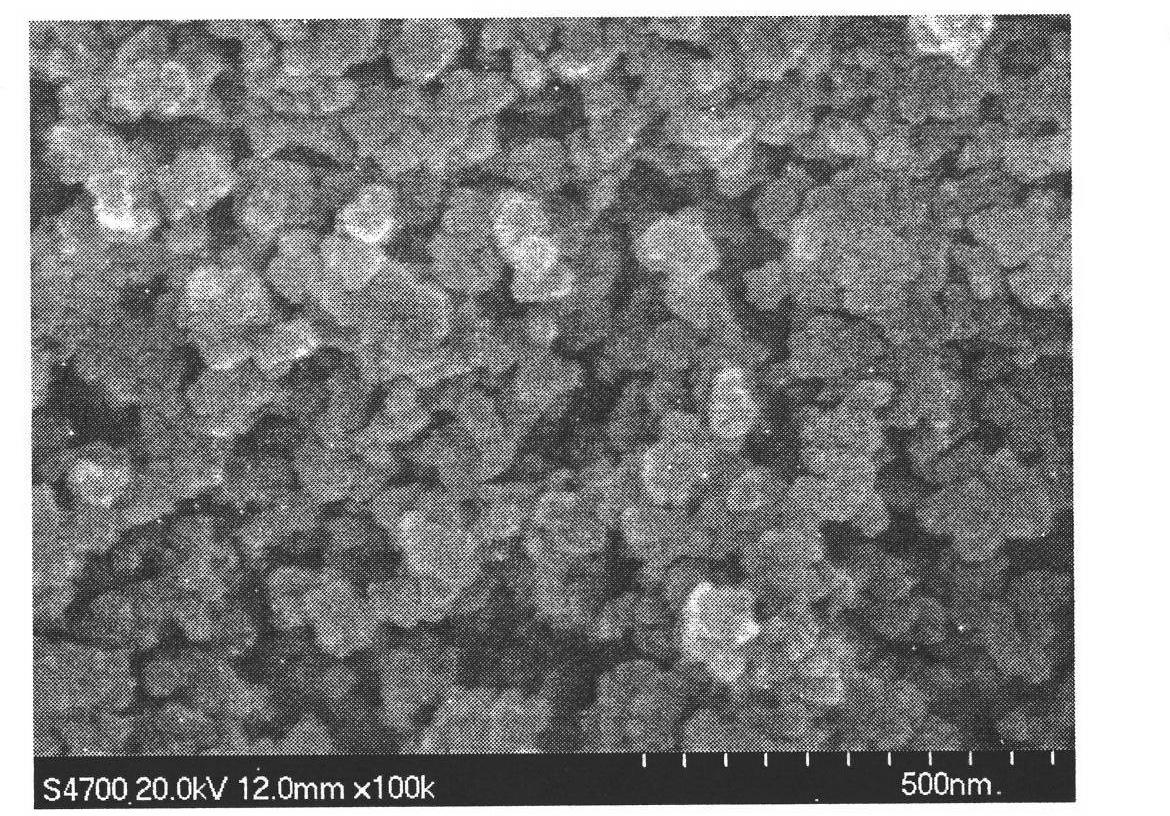

Image

Examples

Embodiment 1

[0016] The preparation mass fraction is 15% Na 2 SiO 3 aqueous solution and 10% H 2 SO 4 aqueous solution. Measure 40mLNa 2 SiO 3 Pour the aqueous solution into a three-necked flask, turn on the stirring device, and slowly add H 2 SO 4 aqueous solution until the pH of the mixture is 3.5. After continuing to stir for 30min, stop stirring and age at this temperature for 7h. The resulting jelly was filtered with suction and washed with deionized water until there was no SO 4 2- , transferred to 110 ° C oven for drying for 12 hours. Grind the dried solid into powder, transfer it to a muffle furnace and heat up to 550°C at a rate of 2°C / min and roast for 4 hours, and the obtained powder is ground and passed through a 100-mesh sieve to obtain the carrier Si-g.

[0017] Measure 0.5mol / L of Ni(NO 3 ) 2 aqueous solution and 0.1mol / L La(NO 3 ) 3 Mix 10mL of each aqueous solution, and the Ni / La (molar ratio) in the metal salt solution is 1:0.2; accurately weigh 1.0630g of se...

Embodiment 2

[0019] Measure 0.5mol / L of Ni(NO 3 ) 2 aqueous solution and 0.05mol / L La(NO 3 ) 3 Mix 10mL of the aqueous solution, and the Ni / La (molar ratio) in the metal salt solution is 1:0.1; accurately weigh 1.1326g of the self-made carrier Si-g (the synthesis steps are as described in Example 1) and mix it with 70mL of deionized water to obtain the carrier Suspension; prepare NaHCO with a concentration of 1.0mol / L 3 aqueous solution as a precipitant. The following preparation steps are the same as in Example 1. Weigh 100g of refined soybean oil and mix it with accurately weighed 0.05g of catalyst, and react for 120min under the conditions of temperature 200°C and hydrogen pressure of 1.5MPa. , The calculated hydrogenation conversion rate was 98.65%.

Embodiment 3

[0021] Measure 0.5mol / L of Ni(NO 3 ) 2 aqueous solution and 0.2mol / L La(NO 3 ) 3 Mix 10 mL of the aqueous solution, and the Ni / La (molar ratio) in the metal salt solution is 1:0.4; accurately weigh 0.9242 g of the self-made carrier Si-g (the synthesis steps are as described in Example 1) and mix it with 70 mL of deionized water to obtain the carrier Suspension; prepare NaHCO with a concentration of 1.0mol / L 3 aqueous solution as a precipitant. The following preparation steps are the same as in Example 1. Weigh 100g of refined soybean oil and mix it with accurately weighed 0.05g of catalyst, and react for 120min under the conditions of temperature 200°C and hydrogen pressure of 1.5MPa. , The calculated hydrogenation conversion rate was 98.52%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com