A kind of heat exchanger ceramic material for intensive flue-cured tobacco room and its preparation method

A technology of ceramic materials and heat exchangers, which is applied in the field of ceramic materials and its preparation for heat exchangers used in dense flue-cured tobacco rooms, can solve the problems of poor thermal shock resistance, low expansion, thermal stability, etc., and achieve good thermal shock resistance , high temperature creep performance, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

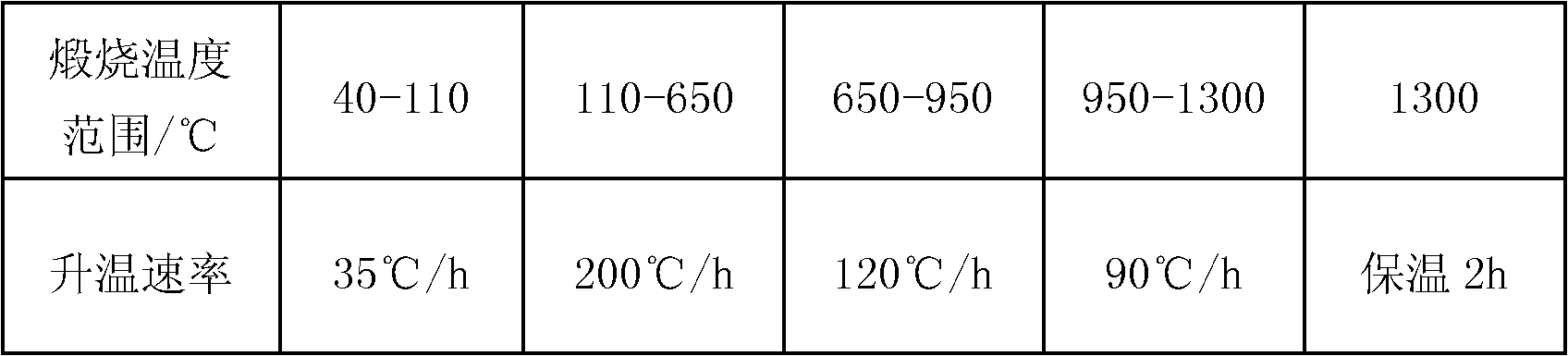

Image

Examples

Embodiment 1

[0025] A method for preparing a heat exchanger ceramic material for a dense flue-cured room, comprising the steps of:

[0026] 1) Preparation of batch materials: according to the mass percentages of each raw material in the batch materials: Yuanan soil 15%, bauxite 40%, purple wood knot 38%, wollastonite 2%, talc 5%, select Yuanan soil, bauxite, purple wood knot, wollastonite and talc;

[0027] The said Yuan'an soil is the soil of Yuan'an County, Hubei Province.

[0028] The dispersant is hexametaphosphoric acid.

[0029] The raw material source used in the present invention and main chemical composition are shown in Table 1:

[0030] The chemical composition (mass percentage composition) of each raw material of table 1

[0031] chemical components

SiO 2

Al 2 o 3

MgO

CaO

Fe 2 o 3

TiO 2

place of origin

Yuan Antu

46.23

41.78

0.11

0.19

0.20

0.20

11.29

Hub...

Embodiment 2

[0042] A method for preparing a heat exchanger ceramic material for a dense flue-cured room, comprising the steps of:

[0043] 1) Preparation of batch materials: According to the mass percentages of each raw material in the batch materials: Yuanan soil 10%, bauxite 50%, purple wood knot 34%, wollastonite 1%, talc 5%, select Yuanan soil, bauxite, purple wood knot, wollastonite and talc;

[0044] The Yuan'an soil, bauxite, purple wood knot, wollastonite and talc are all ground in a ball mill with water, dried and passed through a 300-mesh sieve, and then mixed to obtain batch materials;

[0045] Described Yuan'an soil is the soil of Yuan'an County, Hubei Province;

[0046] Described dispersant is hexametaphosphoric acid;

[0047] 2) Preparation of slurry: according to the mass percentage of each component: batch material 64.25%, water 35%, dispersant 0.75%, select batch material, water and dispersant; add water and dispersant to the batch material in a ball mill Ball milling ...

Embodiment 3

[0053] A method for preparing a heat exchanger ceramic material for a dense flue-cured room, comprising the steps of:

[0054] 1) Preparation of batch materials: according to the mass percentages of each raw material in the batch materials: Yuanan soil 14%, bauxite 33%, purple wood knot 42%, wollastonite 3%, talc 8%, select Yuanan soil, bauxite, purple wood knot, wollastonite and talc;

[0055] The Yuan'an soil, bauxite, purple wood knot, wollastonite and talc are all ground in a ball mill with water, dried and passed through a 300-mesh sieve, and then mixed to obtain batch materials;

[0056] Described Yuan'an soil is the soil of Yuan'an County, Hubei Province;

[0057] Described dispersant is hexametaphosphoric acid;

[0058] 2) Preparation of slurry: according to the mass percentage of each component: batch material 75%, water 24.25%, dispersant 0.75%, select batch material, water and dispersant; add water and dispersant to the batch material in a ball mill Ball milling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com