Microcrystalline Cellulose-Chitosan Fiber

A technology of microcrystalline cellulose and chitosan fibers, applied in the direction of cellulose/protein conjugated rayon, fiber chemical characteristics, conjugated rayon, etc., can solve the problem of poor spinnability and low purity of chitosan fibers , the preparation process is inconvenient and other problems, to achieve the effect of preventing the production of gelatin, saving raw materials, and improving the state of the spot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Chitosan 2.8g, glycerin 0.5g, zinc acetate 1.5g, microcrystalline cellulose 5g, water 90.2ml.

[0017] The concentration of acetic acid used to dissolve chitosan was 2.5g / 100ml.

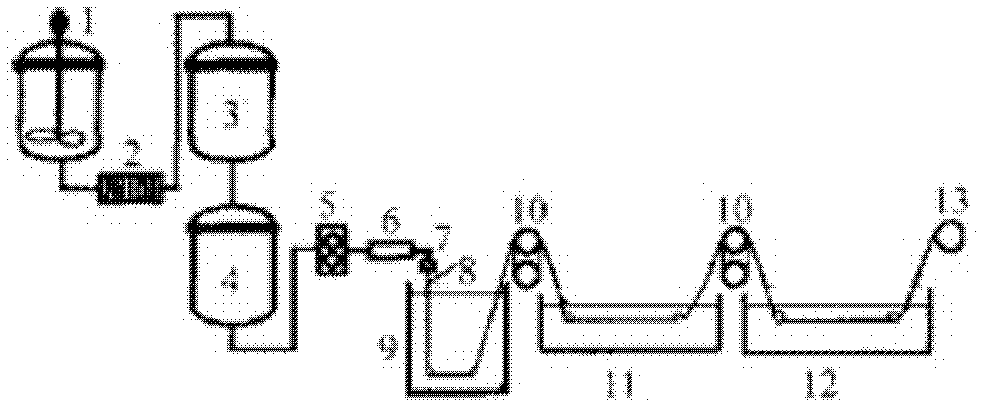

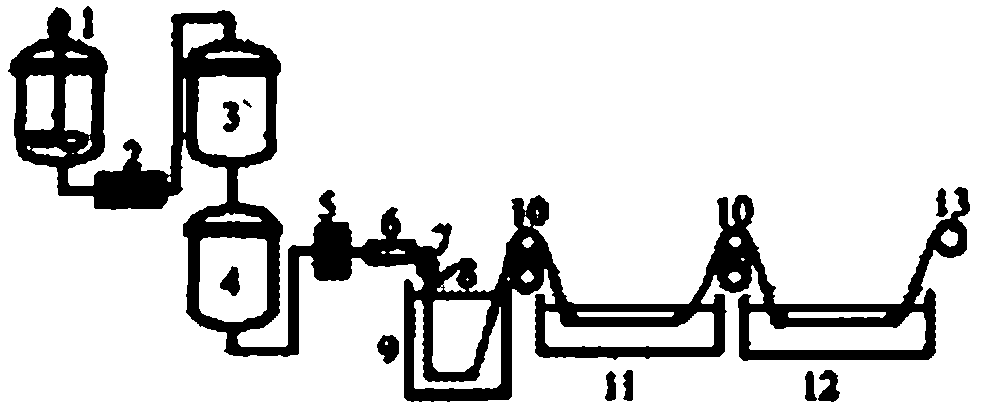

[0018] refer to figure 1 As shown, take the prescribed amount of microcrystalline cellulose, feed it into the distilled water in the dissolution kettle 1, add acetic acid to acidify according to the concentration of 1.5-3.0g / 100ml; weigh chitosan and add the acidified microcrystalline cellulose obtained in step (1). Stir in the crystalline cellulose suspension to fully dissolve chitosan into a clear and transparent light yellow spinning stock solution. Under pressure, the stock solution passes through the plate and frame filter 2 to remove impurities and then enters the slow-release barrel 4. For degassing the stock solution in the stock solution barrel, during spinning, the stock solution passes through the metering pump 5 under nitrogen pressure, and after the filter 6, it is sprayed out f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com