A system for cracking alcohol into alcohol hydrogen as fuel

A technology of alcohol hydrogen and fuel, which is applied in the direction of charging system, fuel heat treatment device, hydrogen, etc. It can solve the problems of not fully displaying the working condition of the pressure alcohol supply pump of the alcohol hydrogen combustion device, low cracking rate, and corrosion of the cylinder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

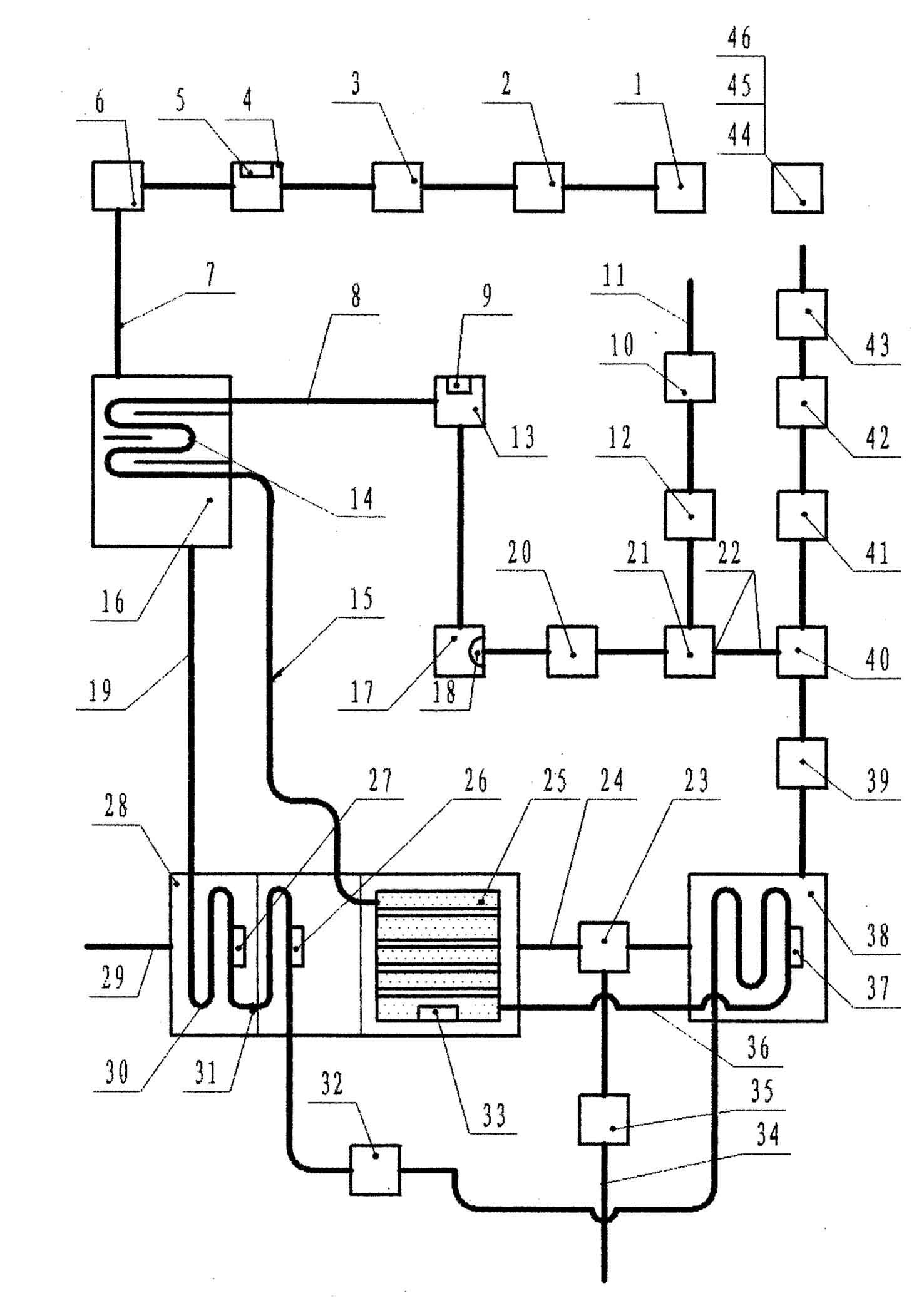

[0081] Embodiment 1, there are two types of automobiles with carburetor and electronic injection, diesel automobiles and other transportations on the market now

[0082] Machinery, including excavators, bulldozers and other engineering construction machinery and equipment, agricultural machinery, construction machinery, gasoline, diesel generators, etc., for vehicle-mounted hydrogen production, they use the hot exhaust gas emitted by the internal combustion engine to heat the alcohol Cracking into the system of hydrogen alcohol as fuel is all ready-to-use, instead of gasoline or diesel fuel for internal combustion engine combustion, all the same, for convenience of discussion, the present invention only discusses carburetor automobiles.

[0083] Behind the exhaust outlet of the original internal combustion engine (39) of the automobile, press figure 1 Install the high heat chamber (38) and the thermometer (37), next to the overheating chamber (38), install the waste gas diver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com