75kv low impedance coaxial cable

A coaxial cable, low-impedance technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problem of low-impedance matching of control systems, coaxial cables do not have the ability to withstand rapid high-voltage shocks, and are not conducive to fast frontier pulse signals Transmission and other issues, achieve the effect of improving light resistance and environmental stress cracking resistance, improving the ability to resist external electromagnetic interference, and stabilizing the internal structure and electrical properties of the cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

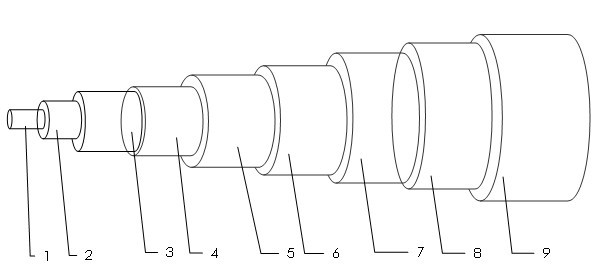

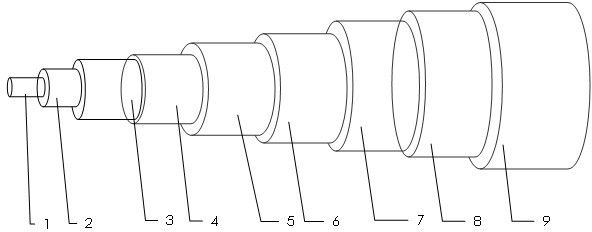

[0007] Such as figure 1 As shown, a 75kV low-impedance coaxial cable includes a filler core 1, an inner conductor 2, an isolation layer 3, a first layer of insulation 4, a second layer of insulation 5, a third layer of insulation 6, an isolation layer 7, and an outer conductor 8 , Sheath 9. Braid multiple strands of tough copper wires outside the filling core 1 as the inner conductor 2 of the cable, and extrude the inner semiconductive layer 3, the extruded cross-linked polyethylene inner insulating layer 4, and the extruded polytetrafluoroethylene insulating layer outside the inner conductor 2 in sequence 5. Extrude the outer insulating layer of cross-linked polyethylene 6, extrude the outer semiconductive layer 7, braid the outer conductor 8 with tough copper wire, and finally extrude a layer of light-resistant and heat-resistant polyethylene sheath 9.

[0008] The filling core 1 is extruded from cross-linked polyethylene, the isolation layer 3 and the isolation layer 7 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com