Method for preparing SAPO-34 molecular sieve with rich Si(4Al) structures and product and application thereof

A SAPO-34, molecular sieve technology, applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve catalyst, molecular sieve characteristic silicoaluminophosphate, etc. Not easy to deactivate, optimize feeding sequence, improve catalyst life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

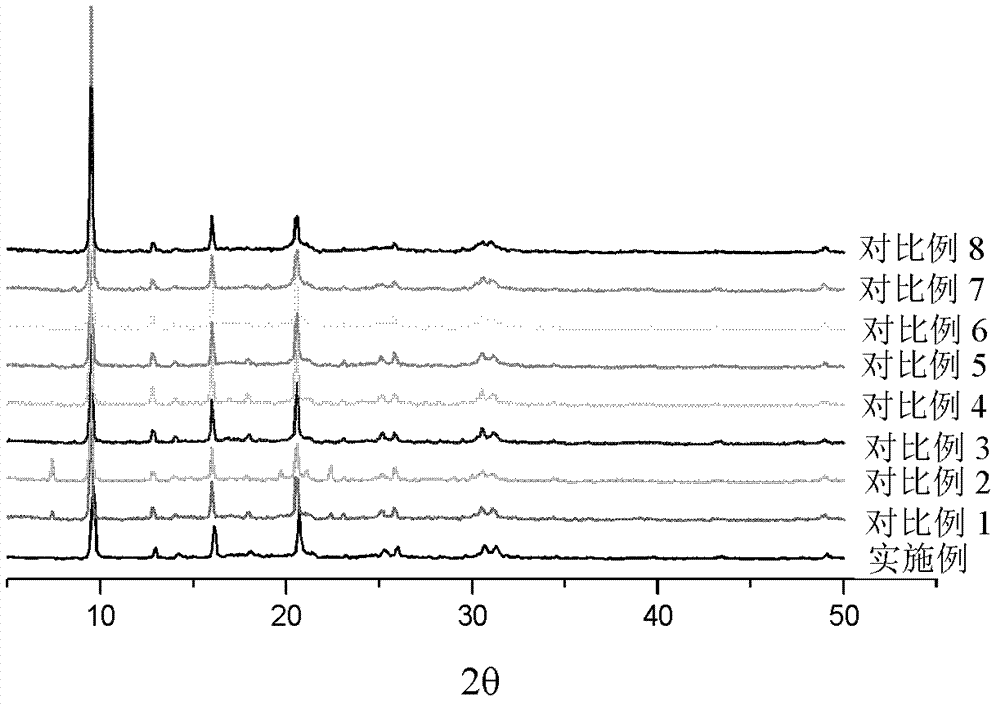

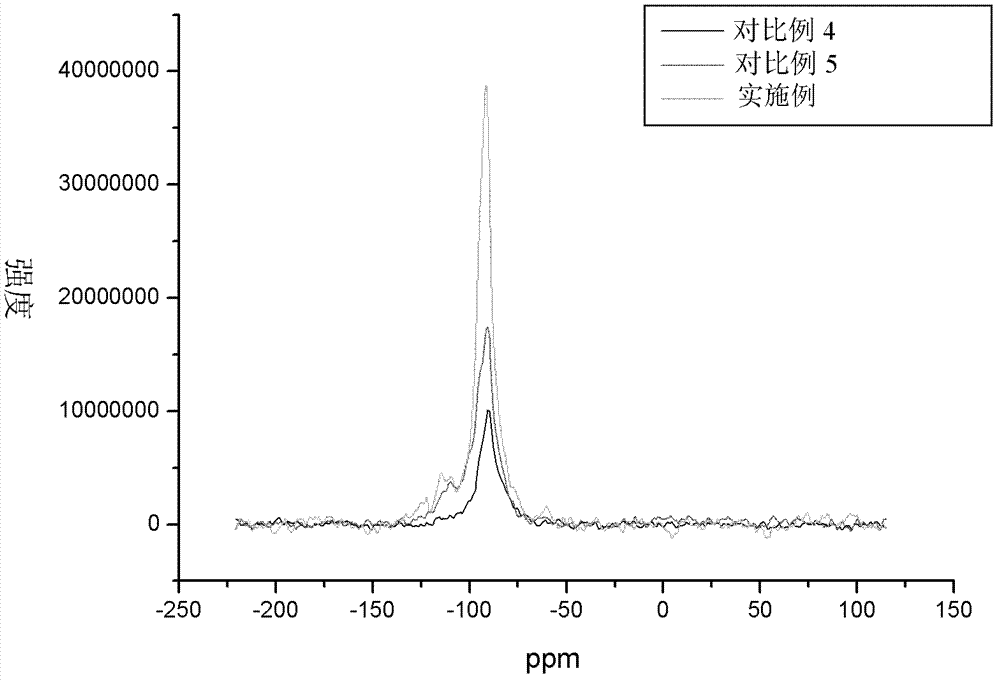

Embodiment 1

[0125] The mixing order of the raw materials is as follows: the aluminum source and the basic composite template are mixed in advance, and then the phosphorus source and the silicon source are added in sequence. Concrete preparation process is as follows:

[0126] Weigh 9.90 g of pseudo-boehmite as an aluminum source, add 20.14 g of water, stir well, and mix for 2 hours. After mixing 18.18 g of triethylamine (TEA) as an organic amine template and 0.08 g of NaF as an auxiliary template, they were added to the pseudo-boehmite solution. Then, 85% H as a phosphorus source 3 PO 4 13.842 g was dissolved in 16.57 g of water, stirred evenly and added to the mixed solution of the aforementioned aluminum source and composite template agent, the reaction was exothermic, and the temperature of the mixed solution rose to 50°C. Dissolve 6.12g of 30% silica sol as a silicon source in 20.06g of water and stir evenly. After the mixture containing phosphorus, aluminum and composite template ...

Embodiment 2

[0132] Embodiment 2: preparation active SAPO-34 molecular sieve catalyst

[0133] The acid-exchanged SAPO-34 molecular sieve raw powders prepared in Example 1 and Comparative Examples 3-8 were calcined at 600°C for 5 hours, pressed into tablets and crushed respectively, and then sieved to obtain the particle size of 20-40 mesh for evaluation.

Embodiment 3

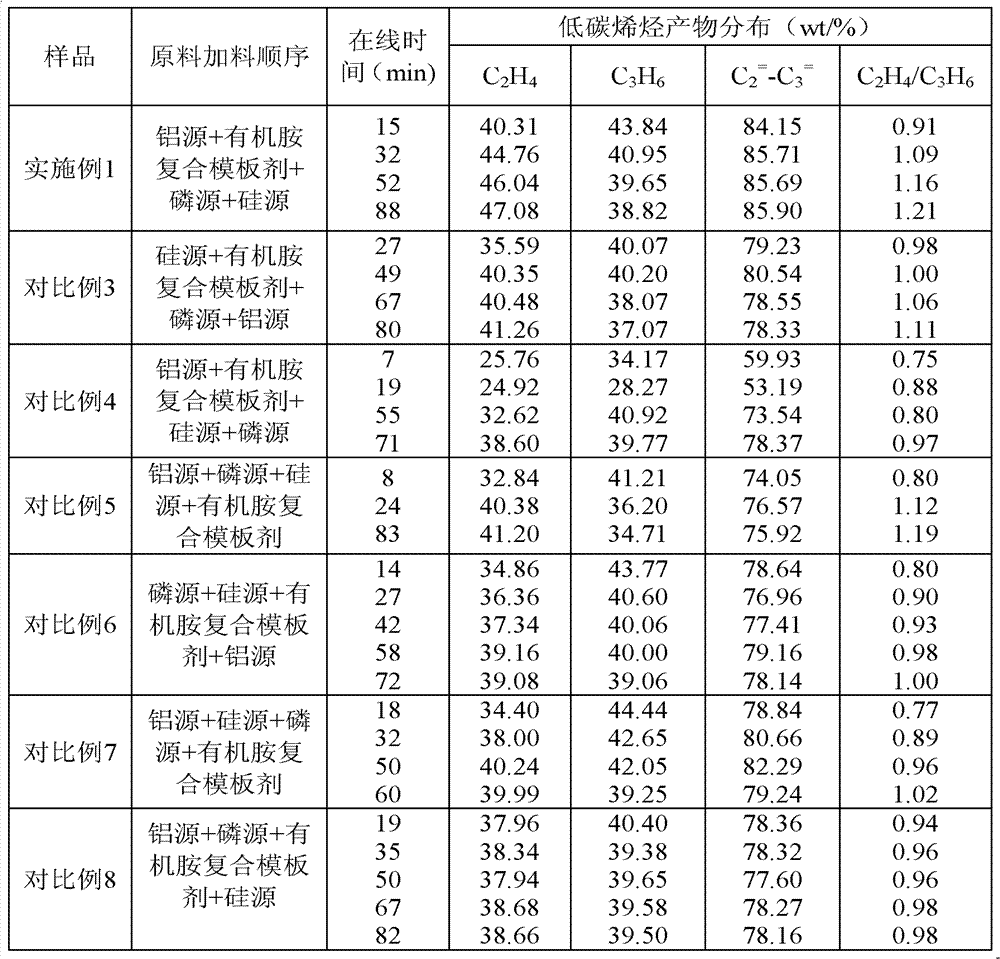

[0134] Embodiment 3: SAPO-34 molecular sieve catalyst evaluation

[0135] Using a fixed-bed catalytic reaction device, the raw SAPO-34 molecular sieve powders obtained in Example 1 and Comparative Examples 3-8 were treated according to Example 2, and evaluation tests were carried out on the obtained catalysts. The experimental conditions are as follows: the catalyst loading is 2g, and N is passed through at 500°C. 2 Activate the catalyst, the reaction temperature is 450°C, the reaction pressure is normal pressure, and the mass space velocity of methanol is 3h -1 , the flow rate of nitrogen is 230ml / min, and the reaction time is defined as the time before the dimethyl ether appears, and the conversion rate of oxygenate is 100%. The results are shown in Table 1.

[0136] Table 1: Evaluation results of obtained molecular sieve catalysts in methanol to olefins reaction

[0137]

[0138] The results in Table 1 show that, compared with Comparative Examples 3 to 8, under the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com