Method for making organic-inorganic compound fertilizer by composting municipal sludge

A technology of municipal sludge and compound fertilizer, applied in fertilizer mixture, application, fertilization device and other directions, can solve the problems of uneven product quality, large difference in nutrient content, large difference in humic acid content, large difference in organic fertilizer effect, etc. Achieving the effect of nutrient balance, less material return and convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

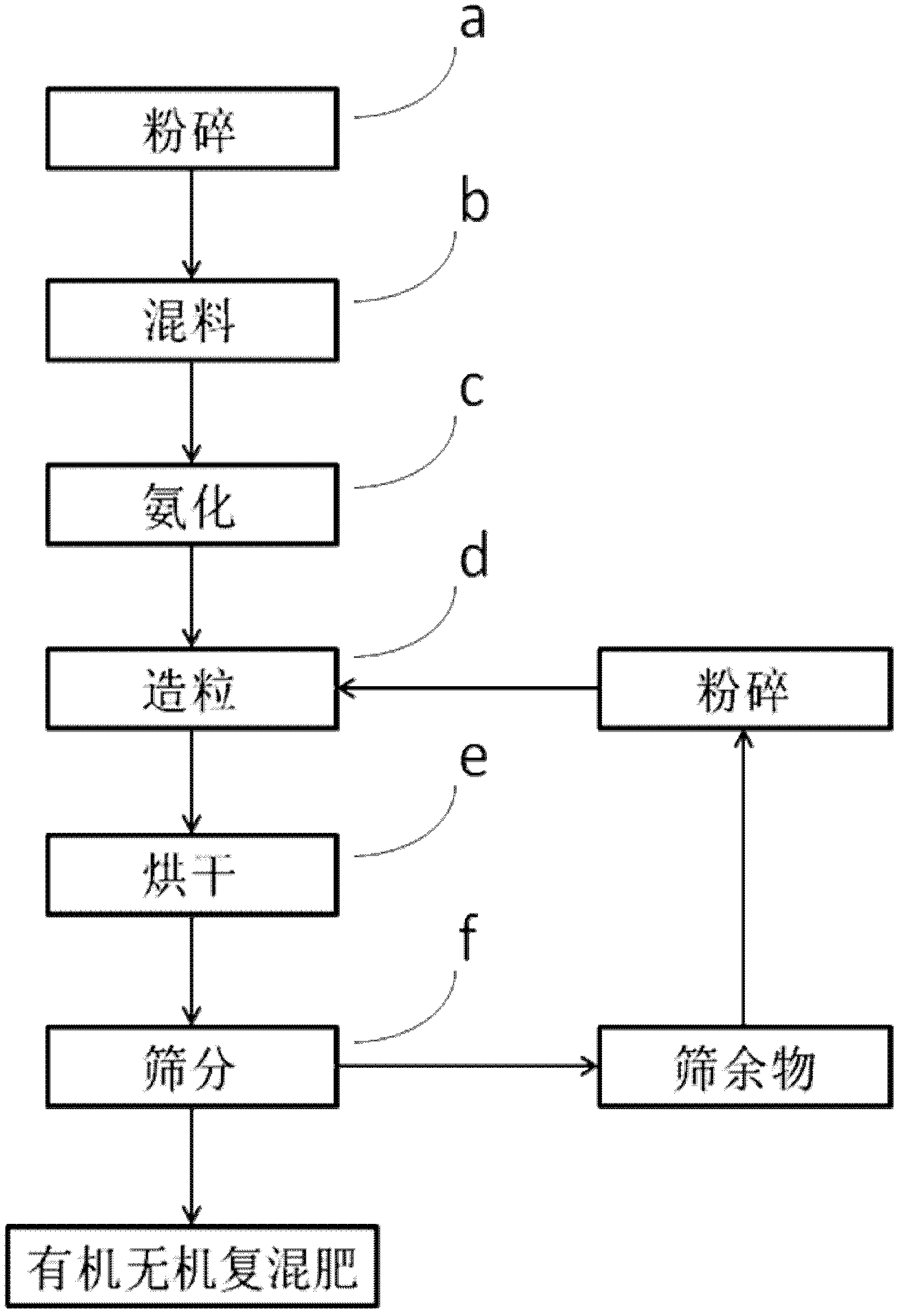

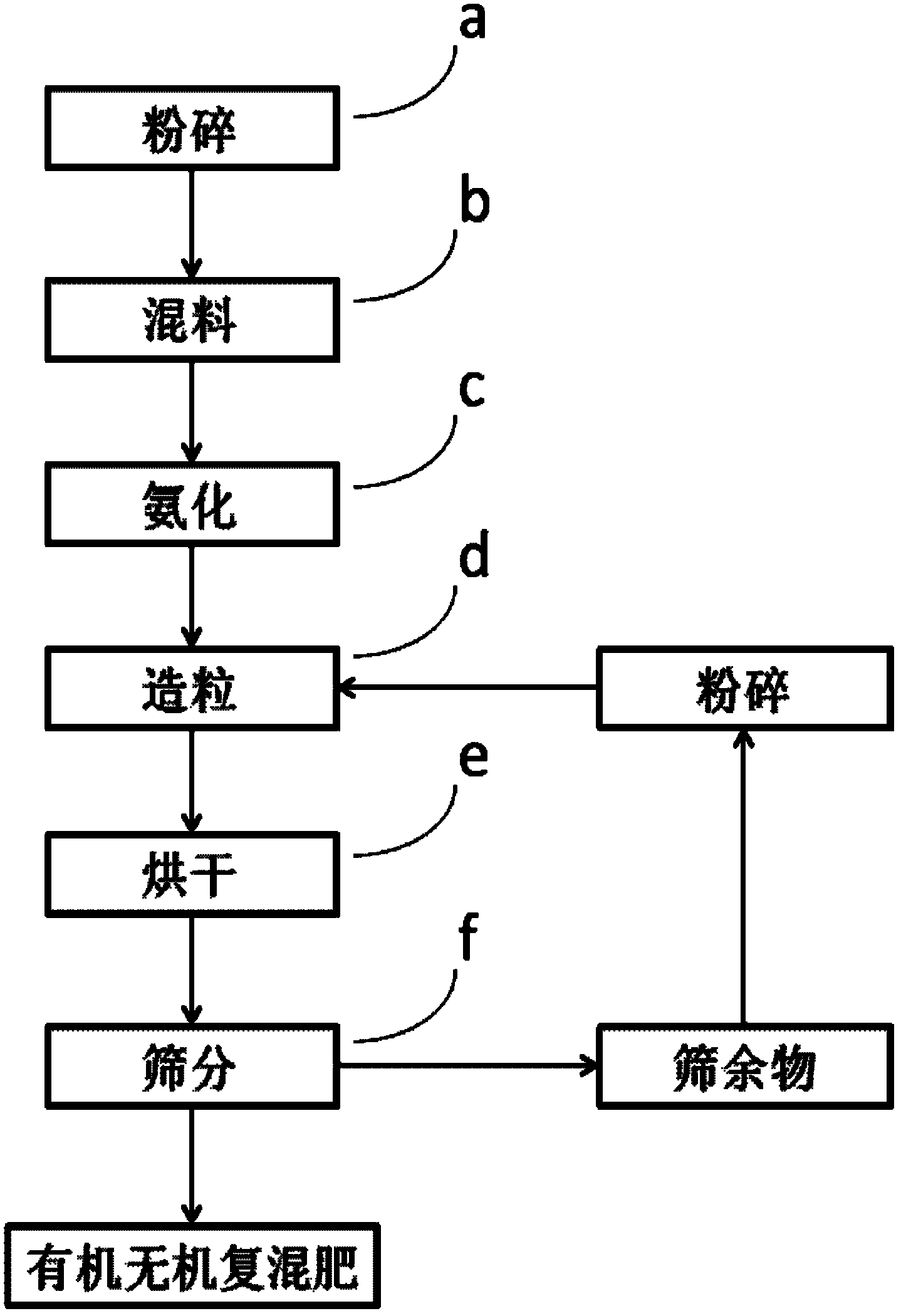

[0039] Specific examples, such as figure 1 shown, including:

[0040] Step 1, pulverization: pulverize the urban sludge compost and weathered coal with a pulverizer respectively, pass through a 60-mesh sieve, and use the sieve for standby;

[0041] The crushing step in the above-mentioned step 1 specifically includes:

[0042] Municipal sludge compost and weathered coal with a water content lower than 20% are ground separately by a ball mill, and passed through a 60-mesh sieve for later use.

[0043] Step 2, mixing: mix 21 kg of ammonium bicarbonate, 60 kg of weathered coal, 140 kg of urea, 55 kg of ammonium monohydrogen phosphate (powder), 175 kg of potassium sulfate (powder), and 550 kg of sludge compost evenly , made into mixed materials;

[0044] The mixing step in the above-mentioned step 2 specifically includes:

[0045] First mix 21 kg of ammonium bicarbonate with 60 kg of weathered coal evenly, then mix with 140 kg of urea, 55 kg of ammonium monohydrogen phosphate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com