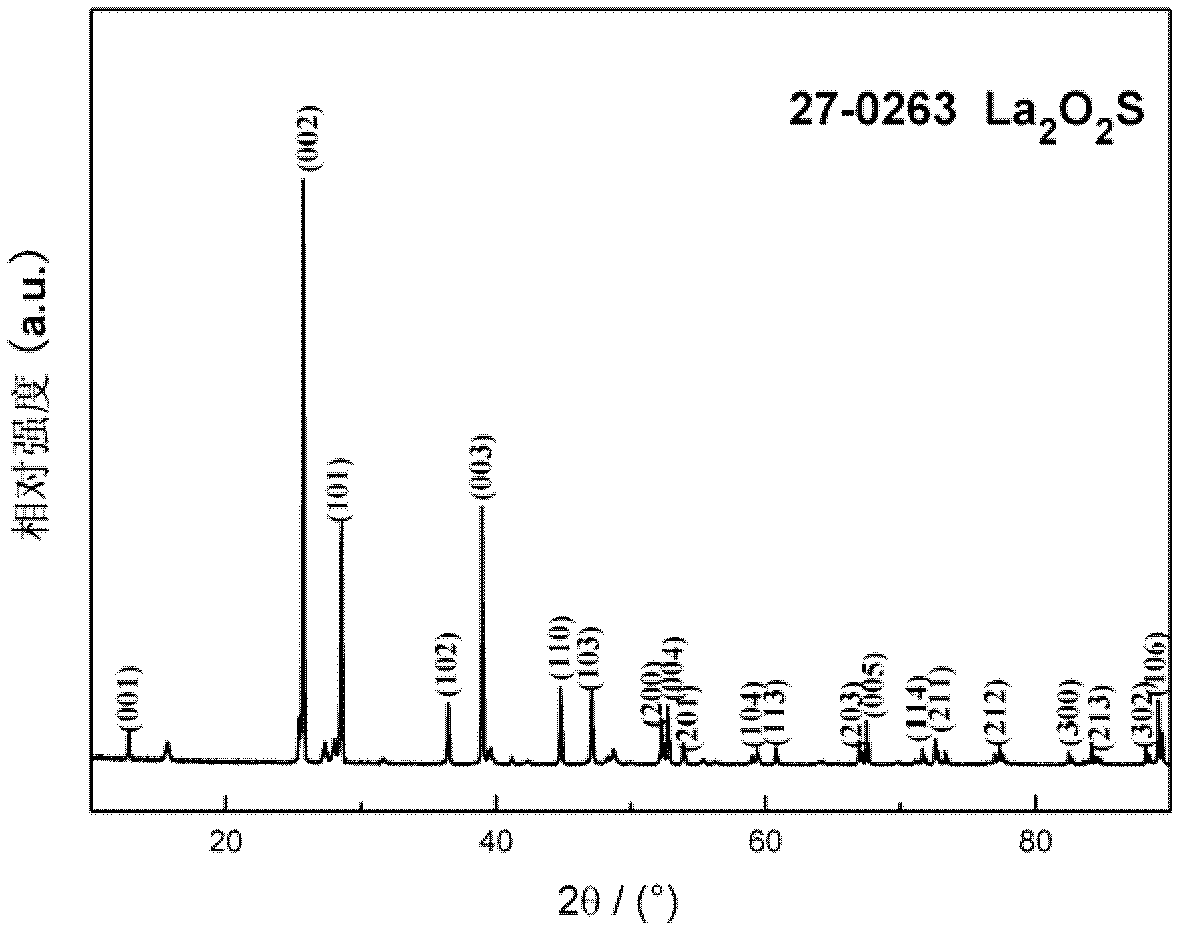

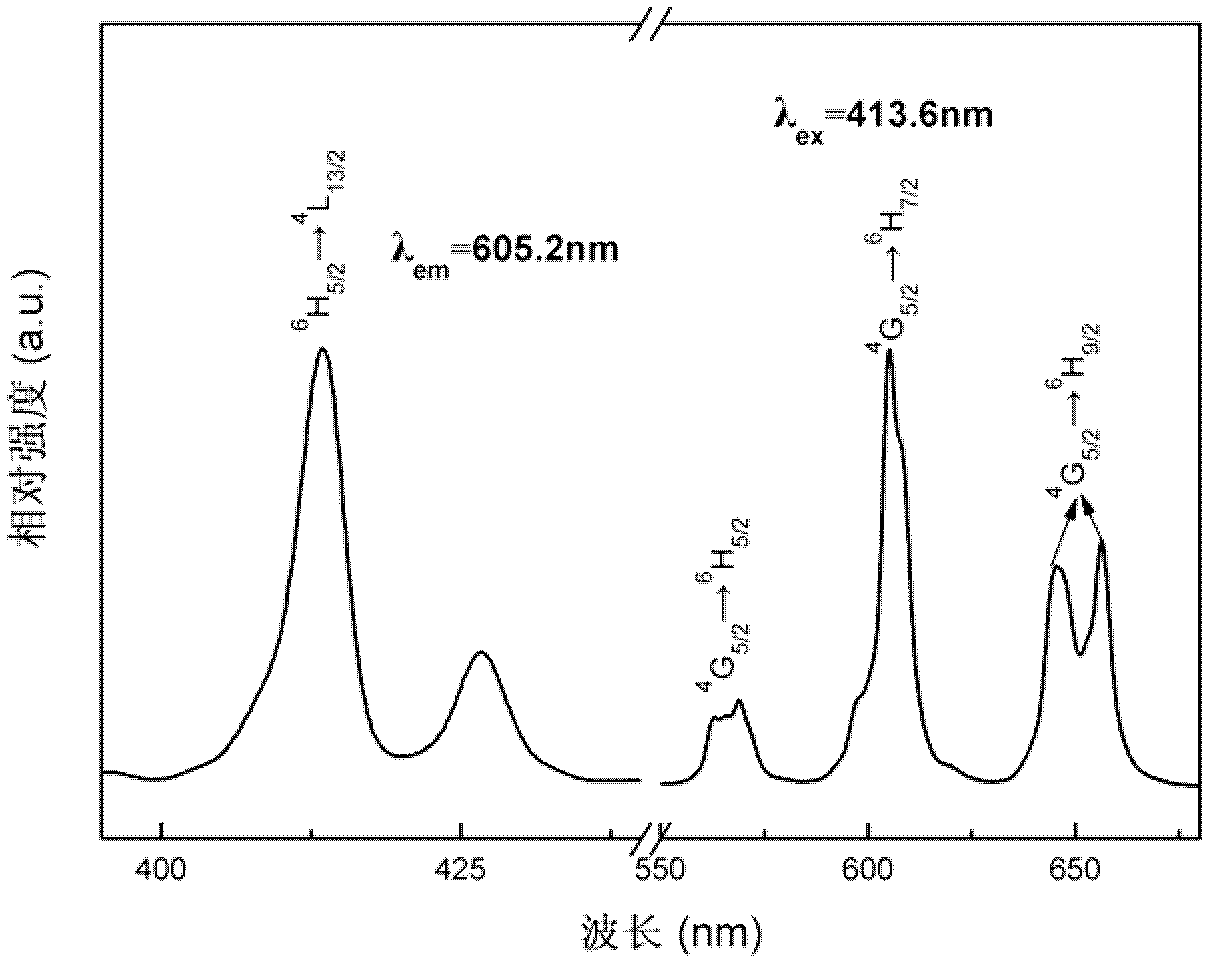

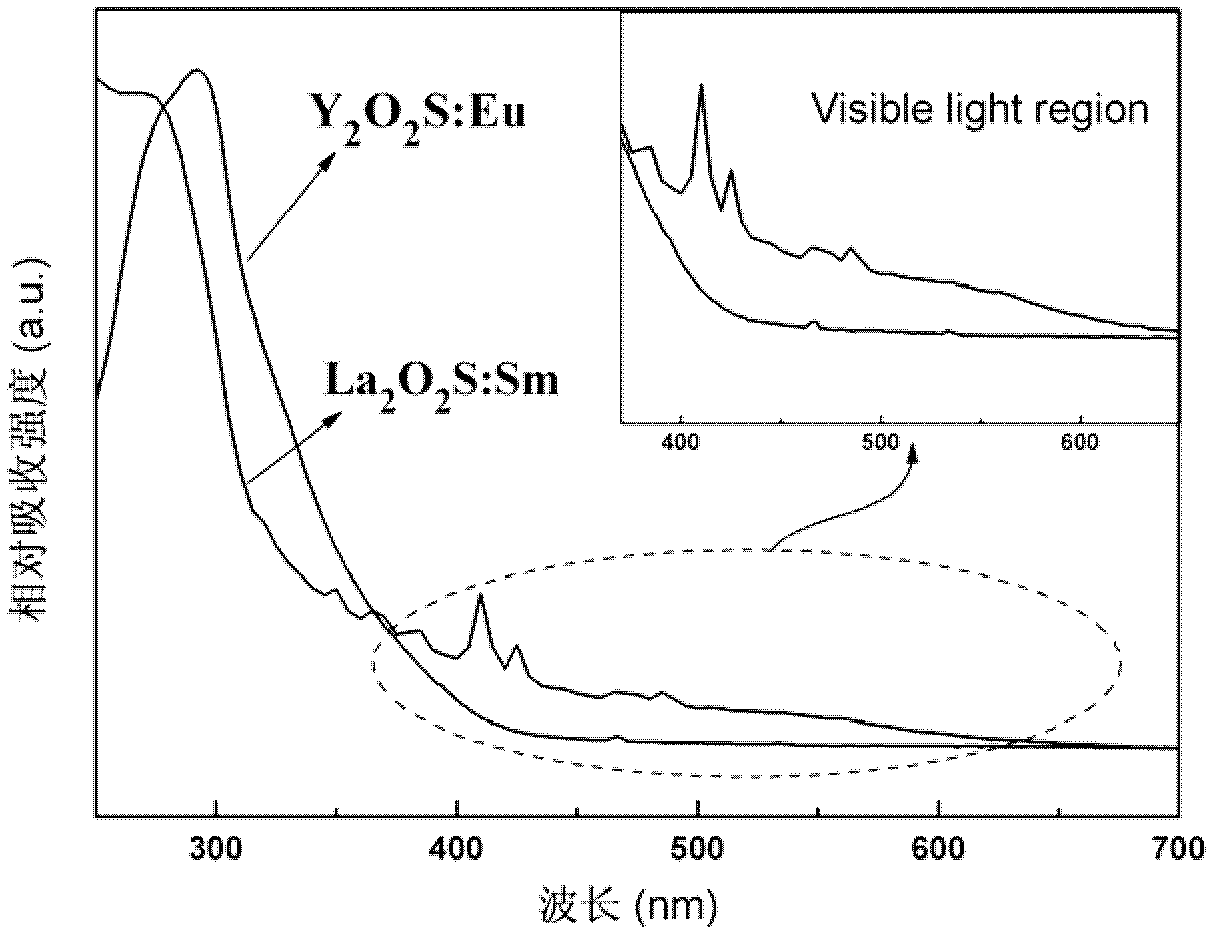

Orange-red long afterglow powder la2o2s:sm3+ and its preparation

A technology with long afterglow and red light, applied in luminescent materials, chemical instruments and methods, etc., can solve problems such as poor moisture resistance, low absorption efficiency, and performance degradation, and achieve low cost, simple production equipment, and strong absorption strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take 0.9286g (0.00285mol) of lanthanum oxide, 0.0522g (0.00015mol) of samarium oxide, and 0.954g (0.009mol) of sodium carbonate, put them in an agate mortar, add a small amount of 99.8% absolute ethanol, mix and grind for 10min, then transfer into a beaker Inside. Then add about 30ml of absolute ethanol with a concentration of 99.8%, use it as a mixing medium, stir by magnetic force for 20 minutes and mix ultrasonically for 10 minutes, after mixing evenly, dry the raw materials in an oven at 60°C for 4 hours. Put the obtained ingredients into an agate mortar, then add 0.48g (0.015mol) of sulfur powder, mix and grind for 10min, and then put the sample evenly into an alumina crucible. Put it into a muffle furnace, sinter in a nitrogen atmosphere, raise the temperature to 1300°C, the heating rate is 3°C / min when it is lower than 800°C, 2°C / min when it is 800-1300°C, and keep it warm for 2 hours at this temperature; finally, in Naturally cool to room temperature under the ...

Embodiment 2

[0037] Take 0.9530g (0.002925mol) of lanthanum oxide, 0.0262g (0.000075mol) of samarium oxide, and 0.954g (0.009mol) of sodium carbonate, put them in an agate mortar, add a small amount of 99.8% absolute ethanol, mix and grind for 15min, and then transfer it into a beaker Inside. Then add about 20ml of absolute ethanol with a concentration of 99.8%, use it as the mixing medium, stir it magnetically for 15 minutes and mix it ultrasonically for 7 minutes, after mixing evenly, dry the raw material in an oven at 70°C for 3 hours. Put the obtained ingredients into an agate mortar, add 0.48 g (0.015 mol) of sulfur powder, mix and grind for 15 min, and then put the sample evenly into an alumina crucible. Put it into a muffle furnace, sinter in a nitrogen atmosphere, raise the temperature to 1250°C, and the heating rate is 4°C / min when it is lower than 800°C, and 3°C / min when it is 800-1250°C. At this temperature, keep it warm for 2 hours; finally, cool it naturally to room temperatu...

Embodiment 3

[0043] Take 0.9628g (0.002955mol) of lanthanum oxide, 0.0157g (0.000045mol) of samarium oxide, and 0.954g (0.009mol) of sodium carbonate, put them in an agate mortar, add a small amount of 99.8% absolute ethanol, mix and grind for 15min, and then transfer them into a beaker Inside. Then add about 40ml of absolute ethanol with a concentration of 99.8%, use it as a mixing medium, stir it by magnetic force for 10 minutes and mix it ultrasonically for 5 minutes, after mixing evenly, dry the raw material in an oven at 80°C for 2 hours. Put the obtained ingredients into an agate mortar, add 0.48g (0.015mol) of sulfur powder, mix and grind for 20min, and then put the sample evenly into an alumina crucible. Put it into a muffle furnace, sinter in a nitrogen atmosphere, and raise the temperature to 1200°C. The heating rate is 5°C / min when it is lower than 800°C, and 2°C / min when it is 800-1200°C. At this temperature, keep it warm for 1 h; finally, cool it naturally to room temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com