Preparation method of cadmium telluride thin film

A thin film preparation and cadmium telluride technology, which is applied in the field of material plating, can solve the problems of polycrystalline thin film lattice mismatch, polycrystalline thin film lattice mismatch, semiconductor material layer without texture, etc., to avoid crystal Lattice mismatch issues, increased grain size, and reduced shape dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the cadmium telluride thin film of the present embodiment is as follows:

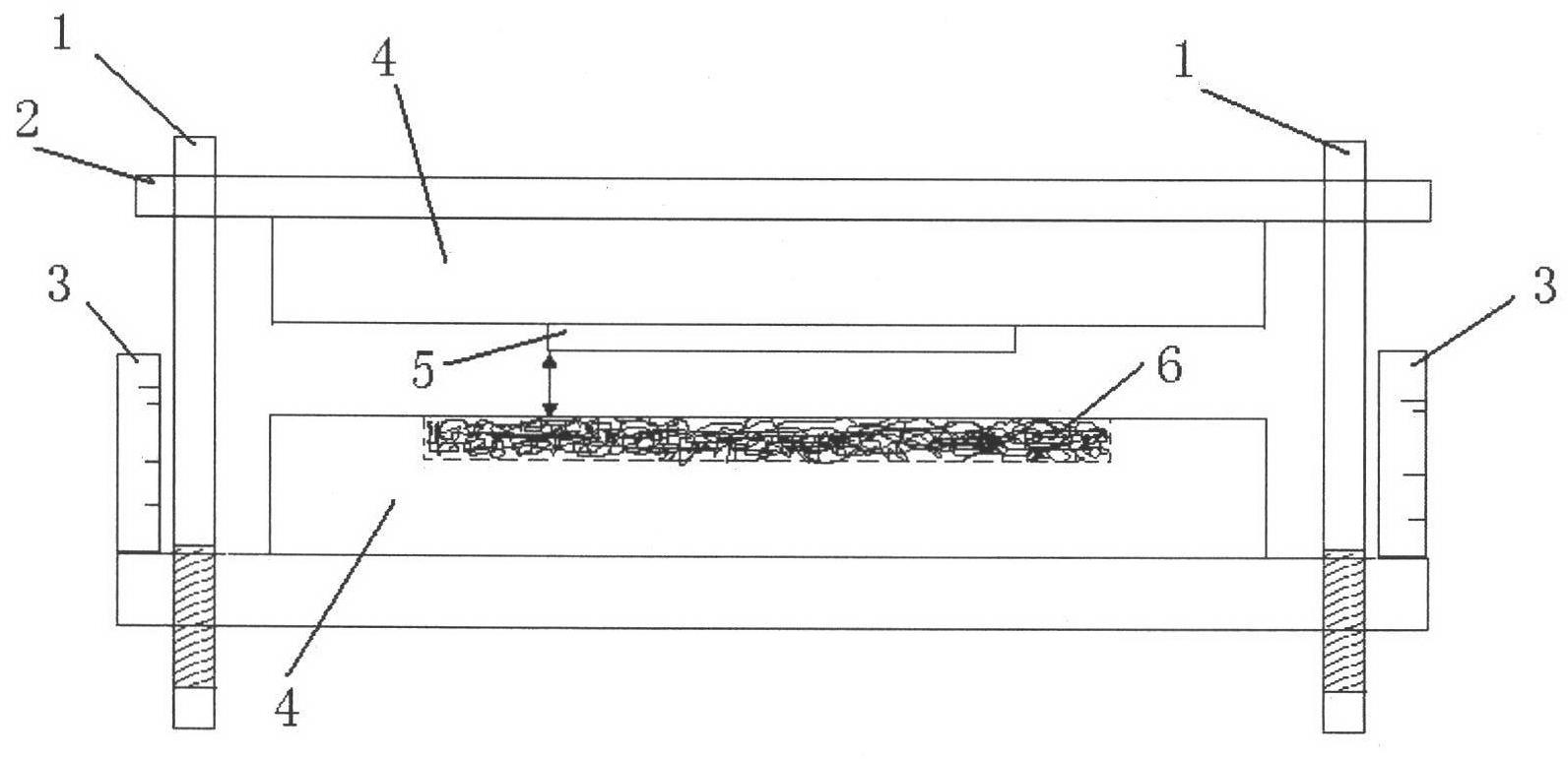

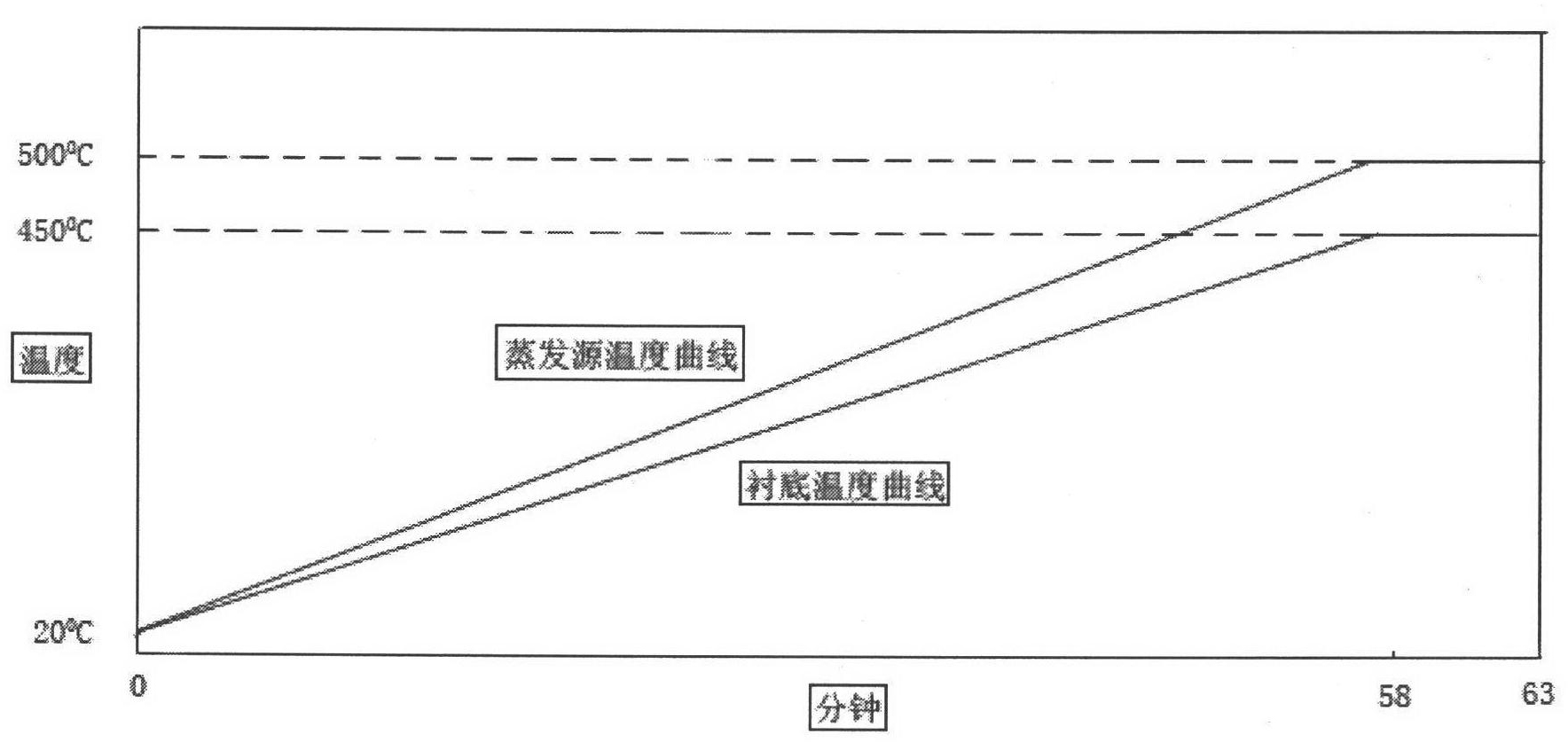

[0034] Step 1: select a glass substrate 5 and a CdTe powder source 6, fix the glass substrate 5 and the CdTe powder source 6 on two graphite blocks 4 facing up and down respectively, so that the glass substrate 5 faces the CdTe powder source 6, and place the Graphite block 4 is put into such as figure 1 In the shelf 2 of the vacuum chamber of the near-space sublimation device shown; according to the ruler 3, the distance between the cadmium telluride powder source 6 and the glass substrate 5 is adjusted to 2 mm with the nut 1, and the air pressure in the near-space sublimation device is adjusted to be 30 Pa. The cadmium chloride powder source 6 and the glass substrate 5 are heated for the first time, the heating temperature of the cadmium telluride powder source 6 is controlled to be 500°C, the heating temperature of the glass substrate 5 is controlled to be 450°C, and t...

Embodiment 2

[0039] This embodiment is an improvement on the basis of Embodiment 1, except that it is the same as Embodiment 1. The difference is:

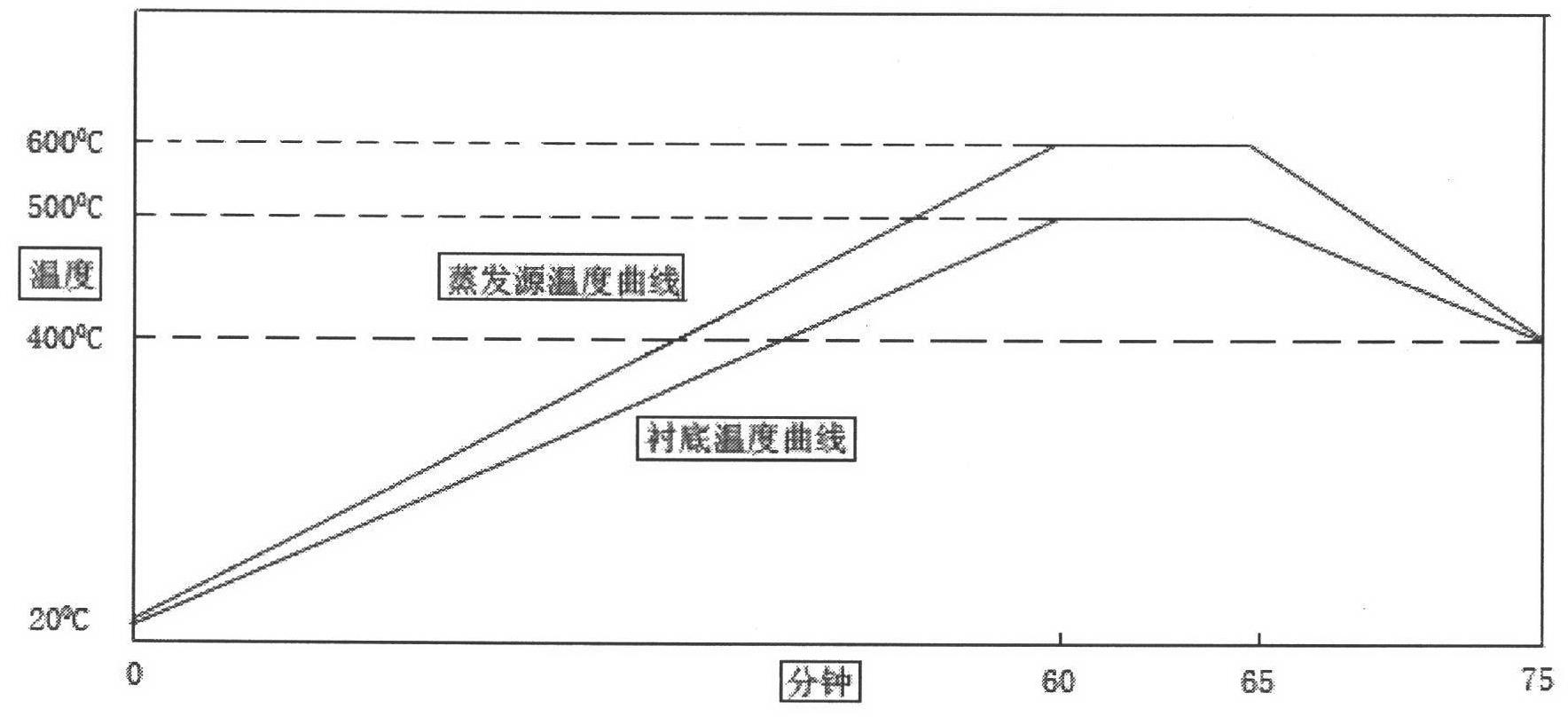

[0040]In step 1, the distance between the glass substrate 5 and the CdTe powder source 6 is adjusted to 3.5mm with the nut 1, and the air pressure in the vacuum chamber of the near-space sublimation device is adjusted to be 200Pa, and the cadmium telluride powder source 6 and the glass substrate 5 are For the first heating, control the heating temperature of the cadmium telluride powder source 6 to 580° C., and control the heating temperature of the glass substrate 5 to 500° C. After reaching the temperature, keep it for 4 minutes, and then cool down to room temperature naturally.

[0041] In step 2, adjust the air pressure in the vacuum chamber of the near-space sublimation device to be 6Pa, carry out the second preheating to the glass substrate 5 and the CdTe powder source 6 before the second heating, control the glass substrate 5 and the CdT...

Embodiment 3

[0044] This embodiment is an improvement on the basis of Embodiment 2, except that it is the same as Embodiment 2. The difference is:

[0045] The glass substrate 5 is changed to a photovoltaic cell substrate (CdS / ITO substrate is commonly used at present).

[0046] In step 1, the distance between the photovoltaic cell substrate 5 and the CdTe powder source 6 is adjusted to be 2.5mm with the nut 1, and the air pressure in the vacuum chamber of the close-space sublimation device is adjusted to be 70Pa, and the photovoltaic cell substrate 5 and the CdTe powder source 6 are For the first heating, control the temperature of the CdTe powder source 6 to 520°C, control the temperature of the photovoltaic cell substrate 5 to 470°C, keep the temperature for 3.5 minutes after reaching the temperature, and then cool down to room temperature naturally.

[0047] In step 2, adjust the air pressure in the vacuum chamber of the near-space sublimation device to be 2Pa, preheat the photovoltaic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com