A self-purifying dust removal low noxsox condensate type super-efficient four-chamber three-circulation coal-water slurry boiler

A technology of coal-water slurry and boiler, which is applied in the field of self-purification, dust removal, low NOxSOx condensate type super-efficient four-chamber three-circulation coal-water slurry boiler, which can solve the problems of latent heat loss and the development of coal-water slurry business, so as to improve the level of environmental protection and thermal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

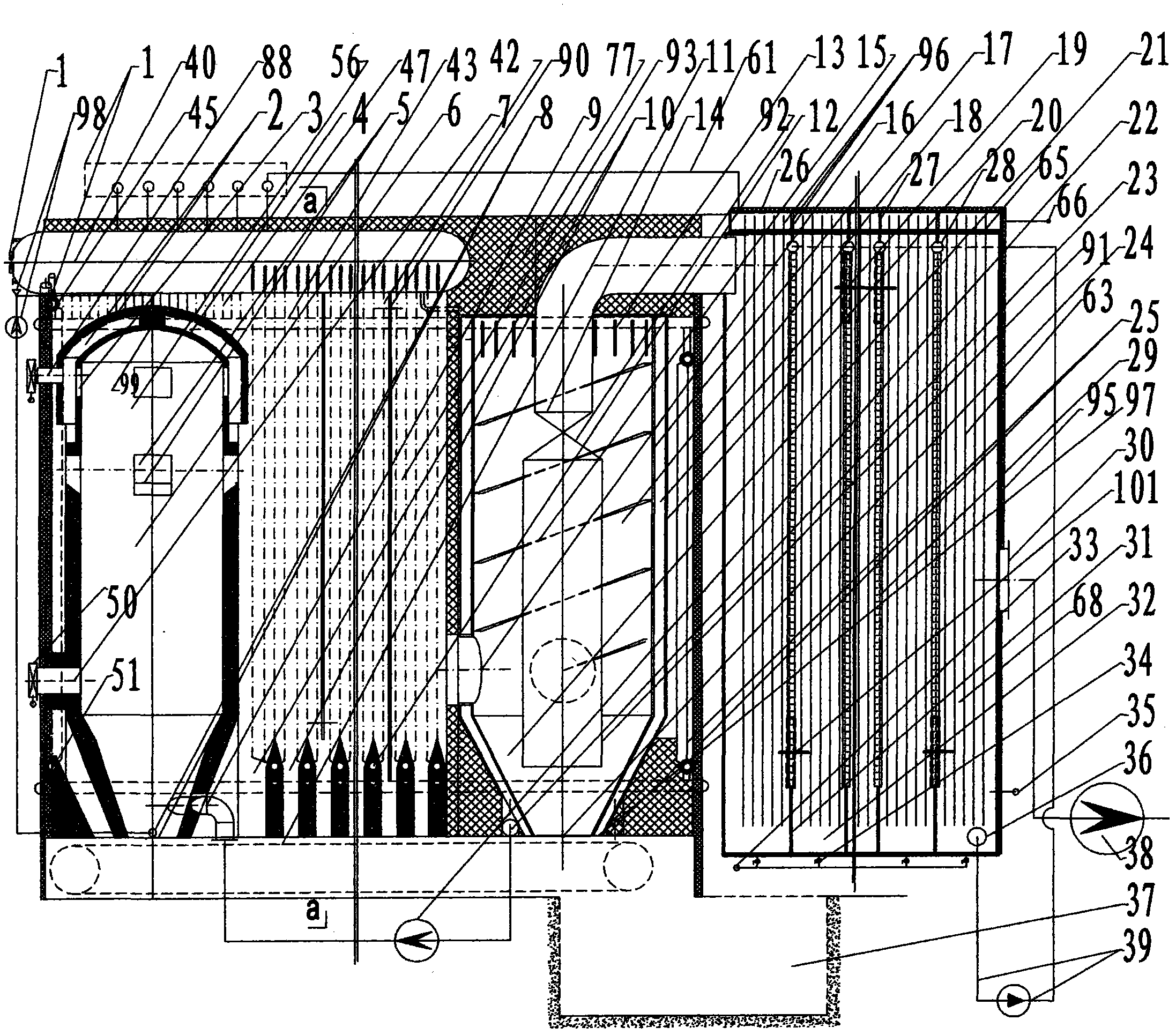

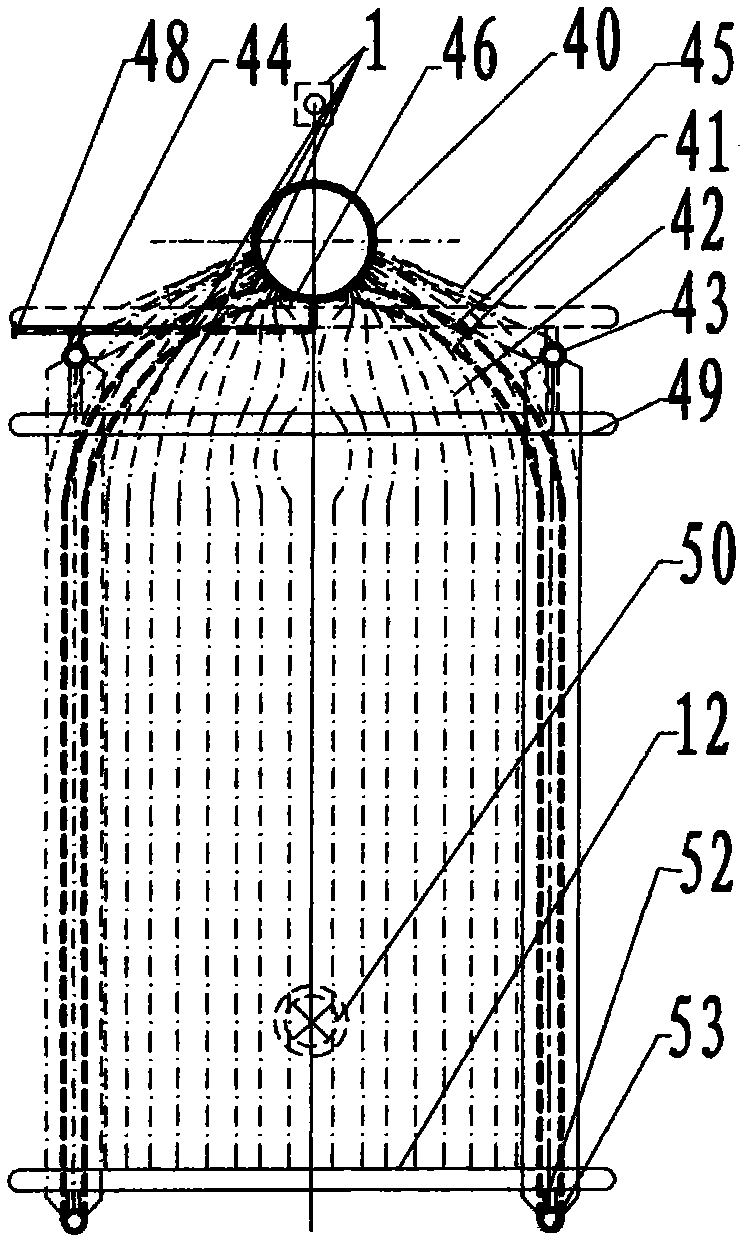

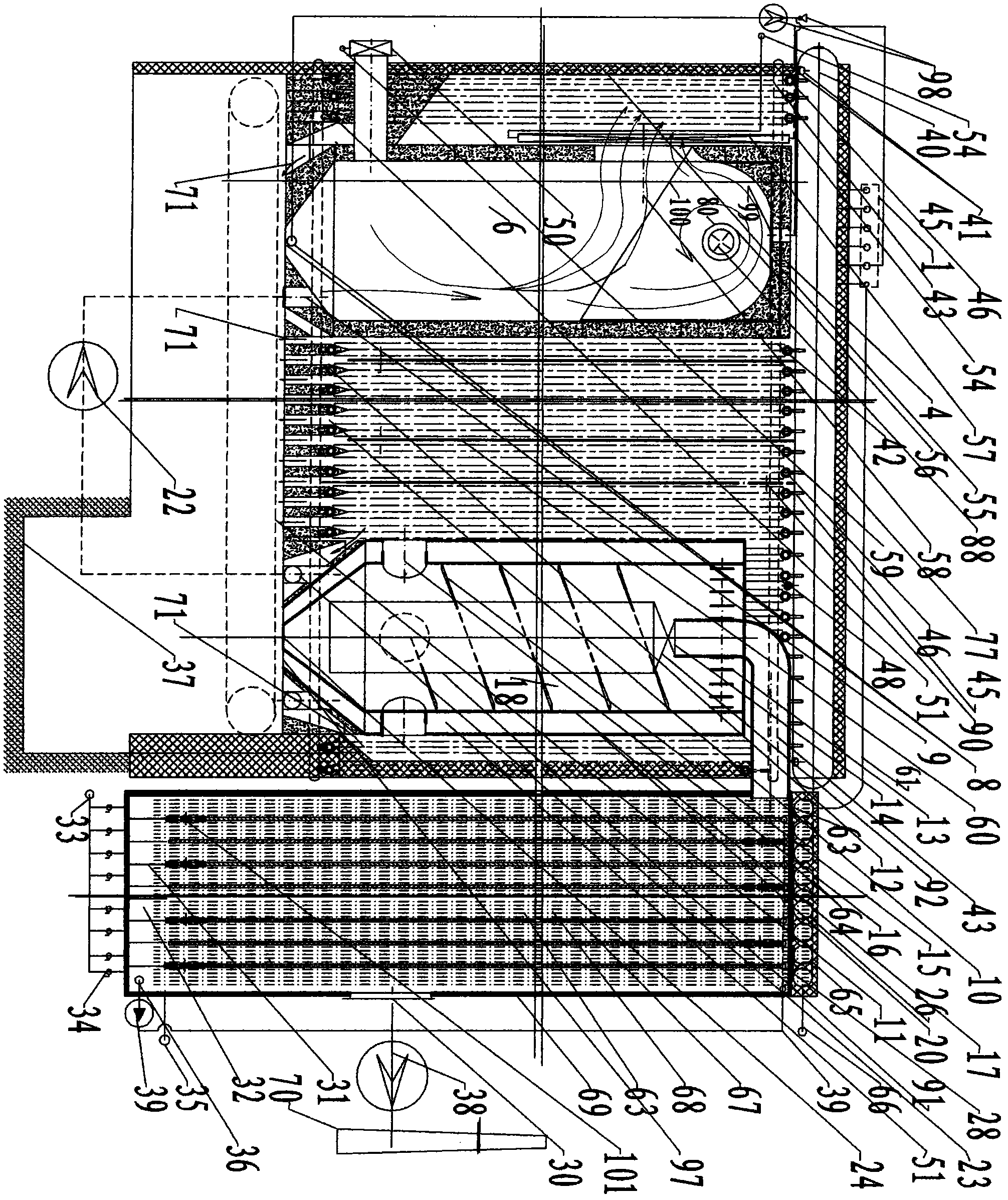

[0012] exist figure 1 Among them, the structure of the four-chamber coal-water slurry boiler, the dry heat furnace 6, the convection heat exchange chamber 93, and the ash separation center chamber 18 are arranged directly under the drum 40 of the pressure-bearing assembly 1, and the superconducting beam chamber 63 is installed in the rear. One. A temperature-controlled sewage burner 88 is arranged on the square front wall of the dry-heat furnace 6, and a coal-water slurry burner 50 is arranged below. With the inner cap 3, open the circulating lime inlet port 99, open the flame outlet 5 around the lower chamber of the cap 6 weeks, and then set the chamber lowering ash outlet 8 at the bottom of the lower funnel cavity, and open the circulating flue gas inlet 9 obliquely on the inner side of the near position, and the flame outlet 5. The external fire enters the tube bundle convection heat exchange chamber 93 of the side tube bundle 47 evenly distributed on three sides. The cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com