Integrated fluid sensor capable of simultaneously measuring density, pressure and temperature of fluid based on micro-electromechanical system (MEMS) technology

A technology of fluid sensor and integrated sensor, which is applied in the direction of measuring fluid pressure by changing ohmic resistance, using directly heat-sensitive electric/magnetic elements, thermometers, etc., which can solve the problem of affecting signals, reduce sensor nonlinearity, and reduce Sensor sensitivity and other issues to achieve the effect of avoiding interference, improving anti-interference ability, and reducing deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

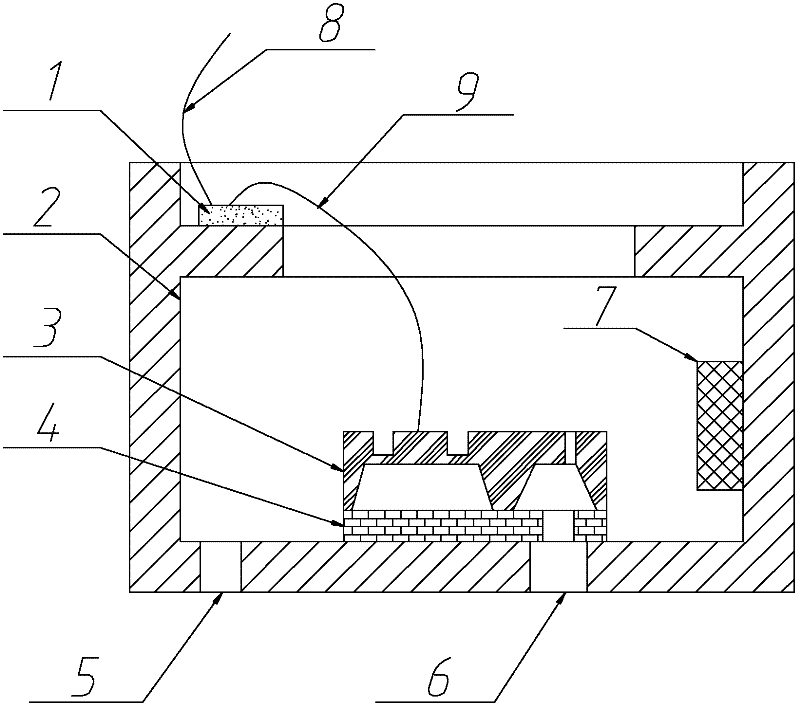

[0020] Below in conjunction with the accompanying drawings, the integrated fluid sensor for simultaneously measuring fluid density, pressure and temperature based on MEMS technology of the present invention is described in detail:

[0021] see figure 1 As shown, the integrated fluid sensor for simultaneously measuring fluid density, pressure and temperature based on MEMS technology of the present invention mainly includes a base 2 configured with a cavity, and the bottom of the base 2 is provided with liquid holes 5 and 6 for the inflow of fluid flow out. The integrated sensor chip 3 and the glass base 4 are packaged together by electrostatic bonding and then packaged on the bottom of the base 2 with epoxy resin bonding or glass frit sintering process. The glass base 4 is provided with a liquid communication hole 5 with the base 2 , 6 communicated openings, so that when the base 2 is completely immersed in the fluid, the fluid flows in from the liquid holes 5-6, so that the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com