A kind of biomineralization material and its preparation method and application

A biomineralization and polymer technology, applied in the direction of dental preparations, digestive system, drug combination, etc., can solve the problems of easy shedding, mismatching mechanical properties, poor long-term effect, etc., and achieve easy industrial production, strong adsorption, and realization The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

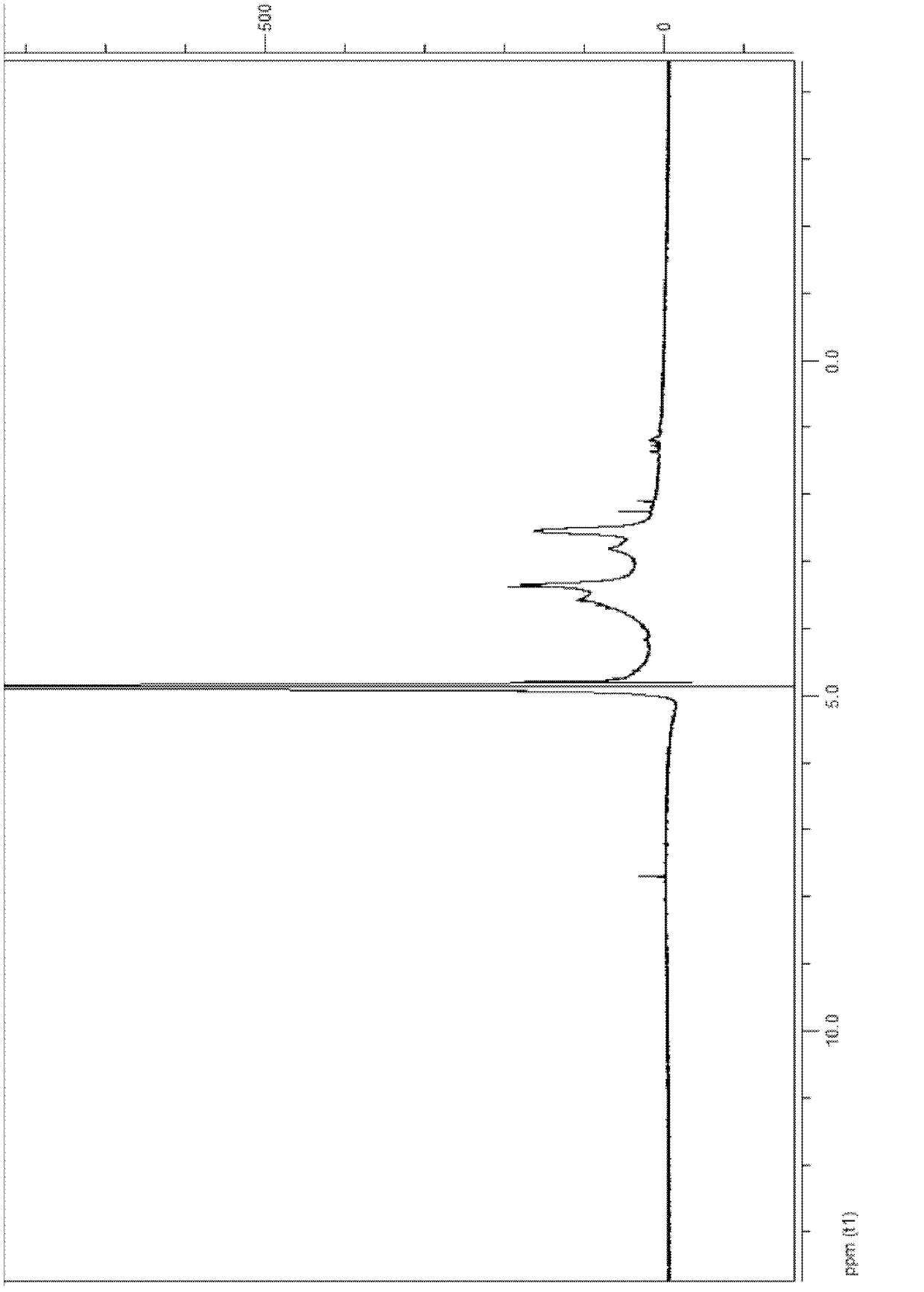

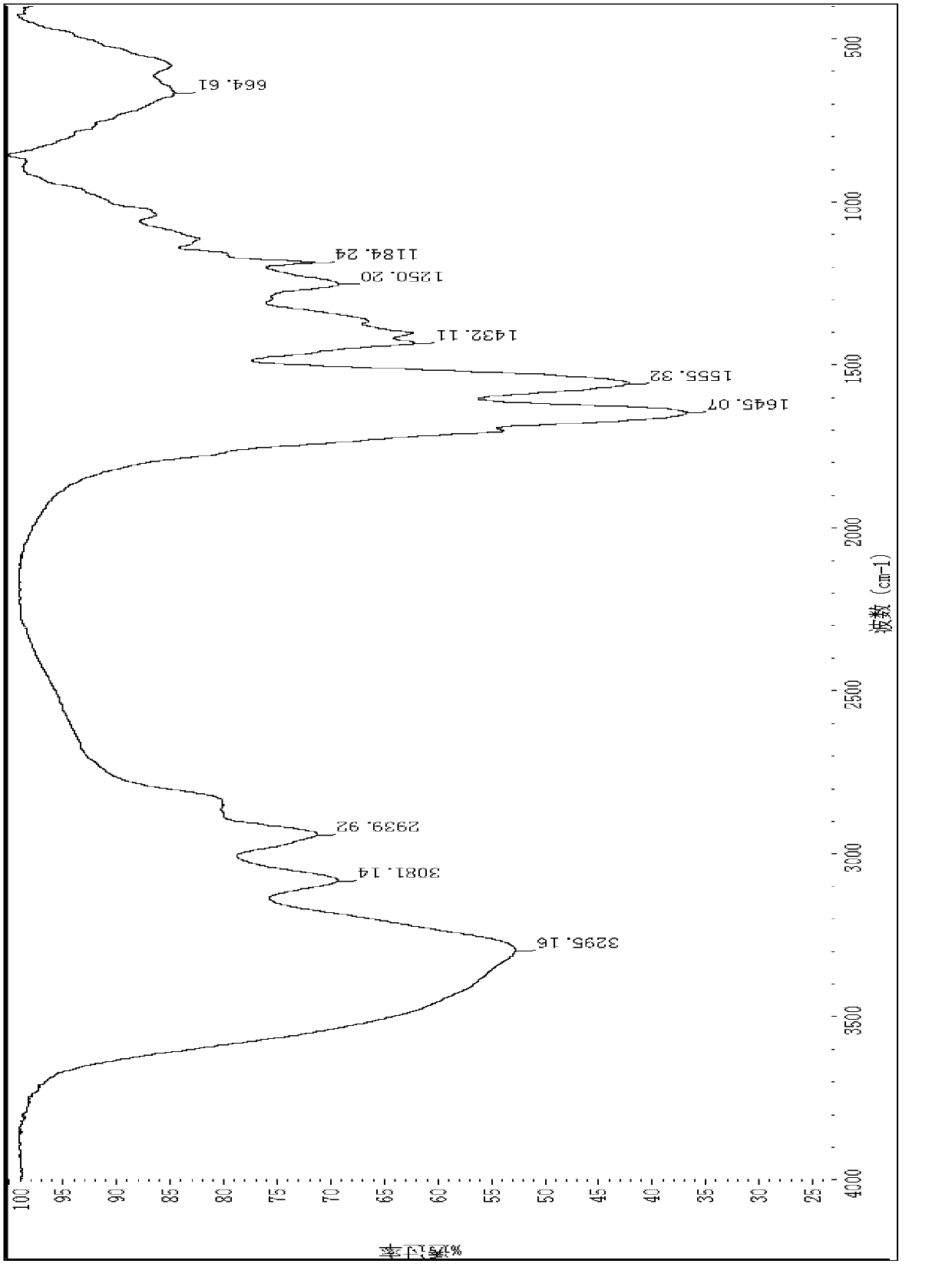

Embodiment 1

[0036] The processing steps of the present embodiment are as follows:

[0037] (1) Synthesis of 3-generation polyamide-amine dendrimers with carboxyl groups

[0038] ① Prepare the first solution

[0039] With 3 generations of polyamide-amine dendrimers (G3.0PAMAM) as solute, with dimethyl sulfoxide (DMSO) as solvent, the proportioning of described solute and solvent is that the concentration of solute is 50 grams per liter of solution. limit, the solute is dissolved in the solvent at normal pressure and room temperature to form the first solution;

[0040] ② Prepare the second solution

[0041] With succinic anhydride (SAH) as solute, with dimethyl sulfoxide (DMSO) as solvent, the proportioning of described solute and solvent is limited to 300 grams per liter of solution with the concentration of solute, under normal pressure, room temperature will The solute is dissolved in the solvent to form a second solution;

[0042] ③Synthesis

[0043] The first solution is 48.78 mi...

Embodiment 2

[0049] The processing steps of the present embodiment are as follows:

[0050] (1) Synthesis of 5th generation polyamide-amine dendrimers with carboxyl groups

[0051] ① Prepare the first solution

[0052] With 5 generations of polyamide-amine dendrimers (G5.0PAMAM) as solute, with dimethyl sulfoxide (DMSO) as solvent, the proportioning of described solute and solvent is that the concentration of solute is 100 grams per liter of solution. limit, the solute is dissolved in the solvent at normal pressure and room temperature to form the first solution;

[0053] ② Prepare the second solution

[0054] With succinic anhydride (SAH) as solute, with dimethyl sulfoxide (DMSO) as solvent, the proportioning of described solute and solvent is that the concentration of solute is 600 grams per liter of solution as limit, under normal pressure, room temperature will The solute is dissolved in the solvent to form a second solution;

[0055] ③Synthesis

[0056] The first solution is 53.2...

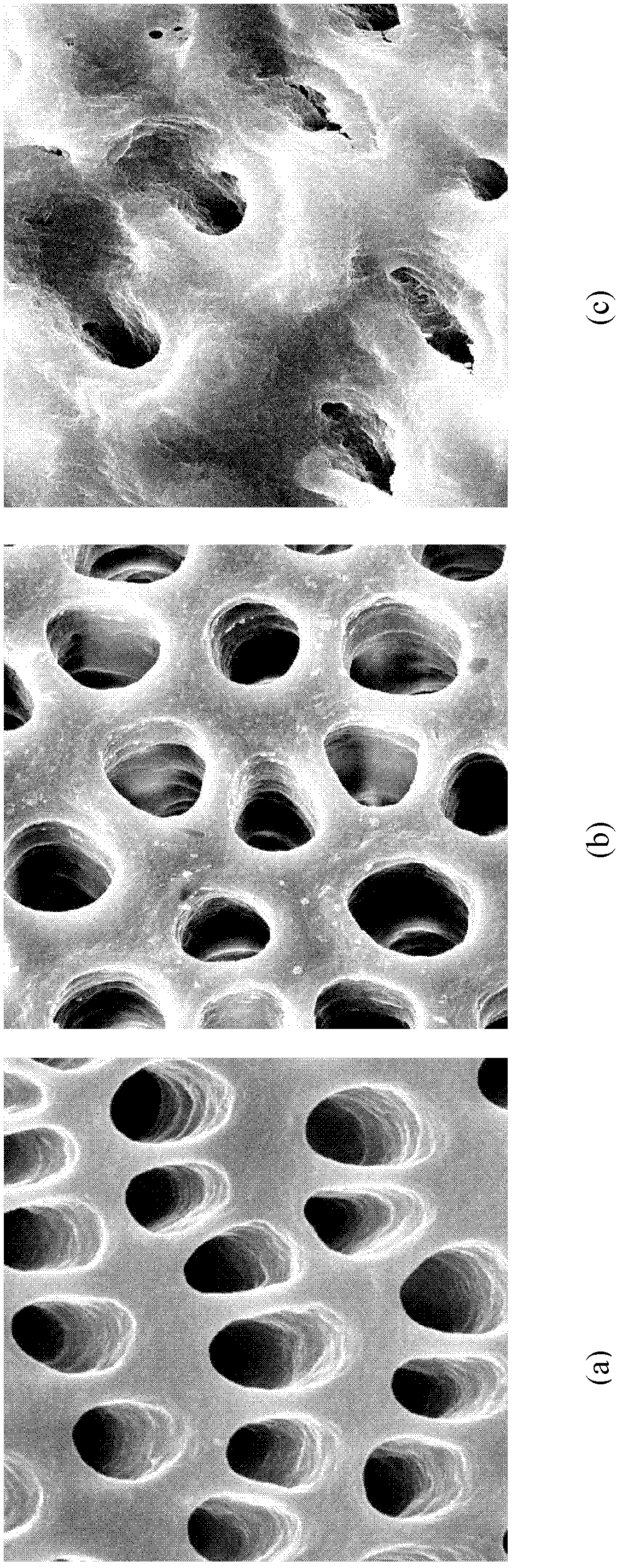

Embodiment 3

[0062] 1. Materials and methods

[0063] 1.1 Materials

[0064] 1.1.1 The specification is HA / M30 hydroxyapatite powder, the water content is less than 0.1%.

[0065] 1.1.2 Reagents

[0066] The end group is the 3rd generation polyamide-amine dendrimers of carboxyl groups (abbreviated as CP in this embodiment, its preparation method sees the step (1) of above-mentioned embodiment 1);

[0067] The biomineralized material prepared in Example 1 above (abbreviated as AP in this example);

[0068] Deionized water;

[0069] PBS buffer, pH 7.4, was purchased from Chengdu Baoxin Biotech.

[0070] 1.2 Method

[0071] 1.2.1 Use deionized water as solvent

[0072] Set CP group and AP group, each group contains 5 parallel samples. Prepare CP and AP respectively into deionized aqueous solutions with a concentration of 1 mg / mL, respectively fill 5 mL of CP aqueous solution and 20 mg of hydroxyapatite powder into 5 test tubes of the CP group and stir for 20 minutes to mix evenly. Put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com