Morpholine modified p-tert-butylphenol-formaldehyde resin and preparation method thereof

A technology of p-tert-butyl and phenolic resin, applied in organic chemistry and other directions, can solve the problems of complex production process, high price, explosiveness, etc., and achieve the effects of simple process, convenient operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

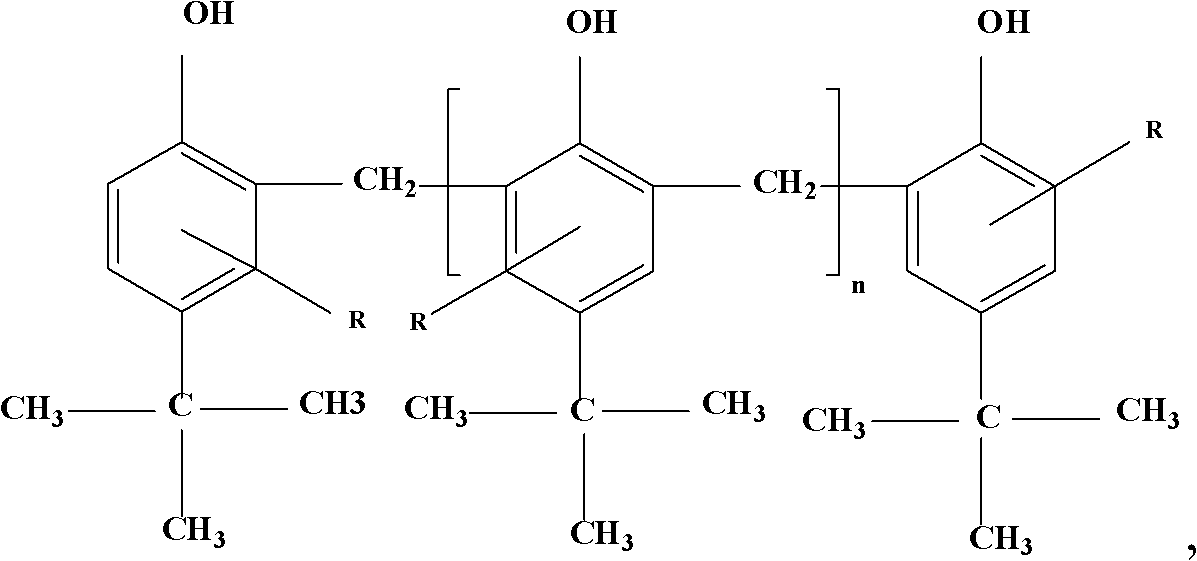

[0034] The preparation method of morpholine modified p-tert-butylphenol-formaldehyde resin is characterized in that it is made of the following components in an amount by weight: 20-35 parts of morpholine, 300-320 parts of p-tert-butylphenol, the first The first step is 125-130 parts of formaldehyde with a weight content of 37%, 0.3-0.5 parts of catalyst, 1.4-2 parts of sodium bicarbonate, 400-500 parts of toluene, and the second step is 25 parts of formaldehyde with a weight content of 37%, hydrochloric acid Or 2-3 parts of oxalic acid, 0.3 parts of active agent;

[0035] The catalyst is an inorganic acid or an organic acid, and the active agent is a copper ammonium complexing agent;

[0036] The described components are made according to the following steps: (1), put in metered p-tert-butylphenol, heat up to 100°C and stop heating, start stirring after all melting, control the stirring speed to 65-85 rpm, stir for half After 1 hour, add the prepared metered catalyst and act...

Embodiment 1

[0046] Add 300g of p-tert-butylphenol into a 1000mL three-necked flask, raise the temperature to 100°C, stop heating, start stirring after it is completely melted, control the stirring speed at 65 rpm, and add 0.3g of copper ammonium complexing agent that has been prepared. Add 0.35g of catalyst, stir for 30 minutes after adding, stabilize the temperature at 60-95°C, add dropwise 125g of formaldehyde in the first step, keep warm at 65-100°C for 3 hours after adding, after the reaction, add metered hydrogen carbonate Sodium 2g (make 20% aqueous solution according to the mass ratio, neutralize, adjust the pH value to about 7-10, control the temperature at 65-100°C and slowly add 26g of measured morpholine, and continue to add slowly after adding The second step is 25g of formaldehyde (adding in about 45 minutes). After the addition, keep warm at 65-100°C for 1.5 hours. If the material is thicker, add 50g of toluene, and then add 2.6g of 31% hydrochloric acid solution measured by ...

Embodiment 2

[0048] Add 310g of p-tert-butylphenol into a 1000mL three-neck flask, raise the temperature to 100°C and stop heating, start stirring after it is completely melted, control the stirring speed at 85 rpm, and add 0.3g of copper ammonium complexing agent that has been prepared and measured Add 0.5g of catalyst, stir for 30 minutes after adding, stabilize the temperature at 60-95°C, add dropwise 130g of formaldehyde in the first step, keep warm at 65-100°C for 3 hours after adding, after the reaction, add metered amount of hydrogen carbonate Sodium 1.8g (make 20% aqueous solution according to mass ratio, carry out neutralization, adjust pH value to be about 7-10, control temperature at 65-100 ℃ and slowly add metered morpholine 35g, continue to drop slowly after adding Add 25g of formaldehyde in the second step (adding in about 45 minutes), keep warm at 65-100°C for 1.5 hours after adding, if the material is thicker, add 50g of toluene, and then add 2.6g of 31% hydrochloric acid so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com