Preparation method of porous pyramid silicon surface light-trapping structure for solar cells

A technology of pyramid structure and light-trapping structure, which is applied in the field of solar cells, can solve the problems of high operating cost, complex equipment, and poor effect, and achieve good repeatability, short processing time, and good anti-reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

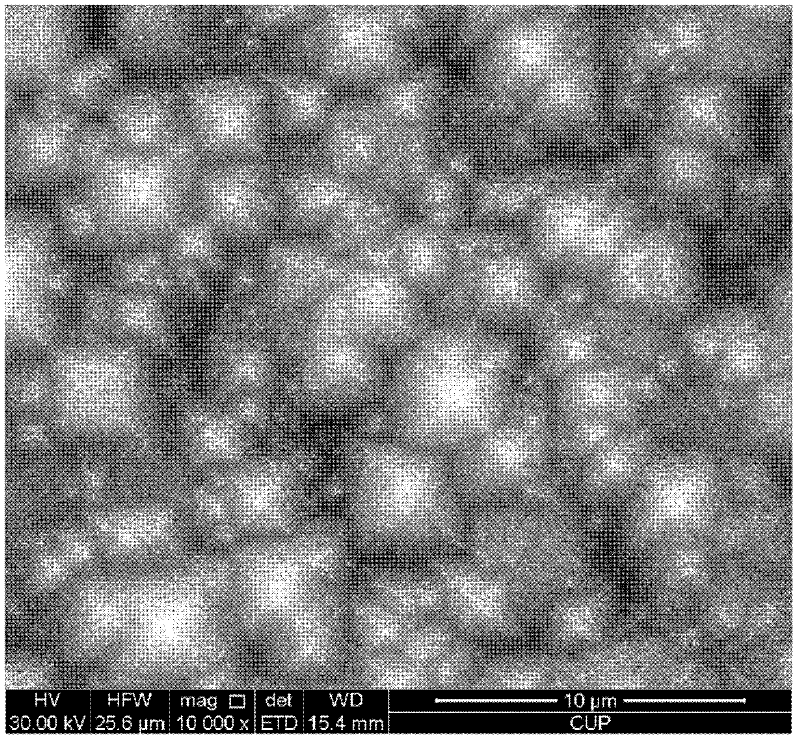

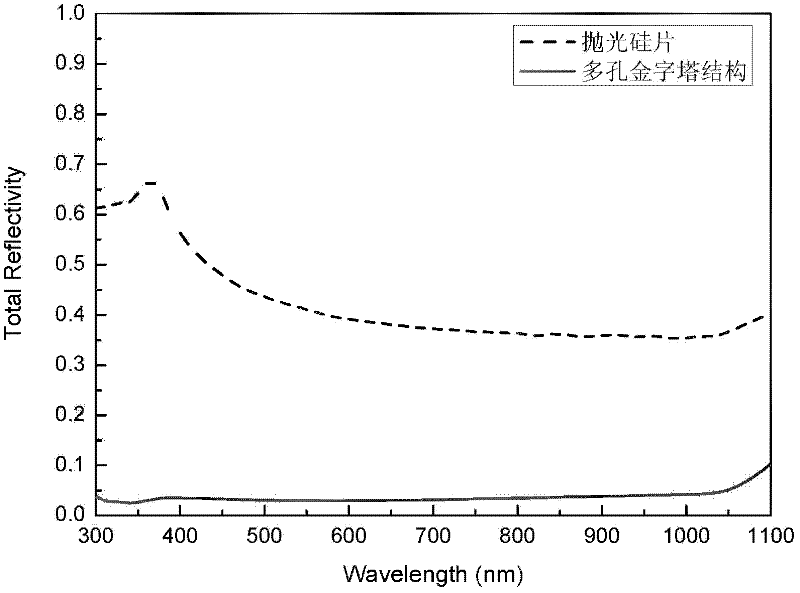

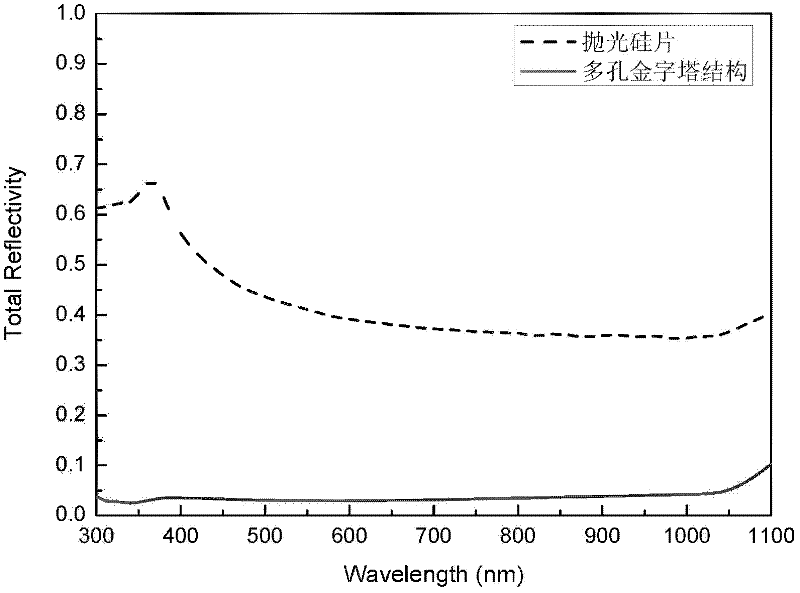

Image

Examples

Embodiment 1

[0021] 1. Use a (100)-oriented monocrystalline silicon wafer with a resistivity of 7-13Ω·cm, ultrasonically clean it in acetone for 10 minutes, rinse it with deionized water for 2 minutes; then soak it in the CP-4A mixed solution at room temperature for 5 minutes , rinse with deionized water for 2 minutes, wherein the CP-4A solution is mixed according to the volume ratio of 3:5:3:22 by 40wt% hydrofluoric acid solution, nitric acid, absolute ethanol and deionized water, the mass of nitric acid The fraction is 65% to 68%; then soak in hydrofluoric acid with a concentration of 7.3mol / L at room temperature for 5 minutes, rinse with deionized water with a resistivity above 16MΩ·cm for 2 minutes, and dry in vacuum;

[0022] 2. Corrode in a water bath at 70°C for 30 to 40 minutes (for example, 35 minutes) with an alkaline etchant to etch out the pyramid suede on the surface, wherein the alkaline etchant is a mixed solution of potassium hydroxide, isopropanol and deionized water. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com