Novel photocatalytic sensitizer and preparation method thereof

A sensitizer, photocatalytic technology, applied in the field of photochemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

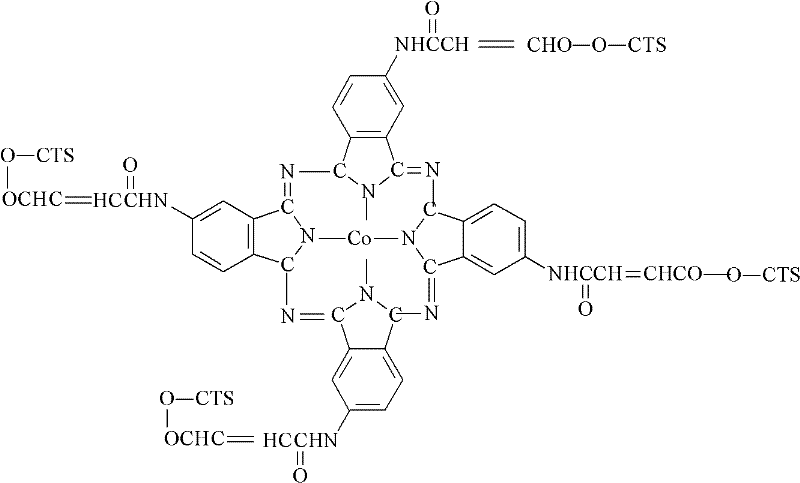

[0023] A preparation method of a photocatalytic sensitizer, comprising the following steps,

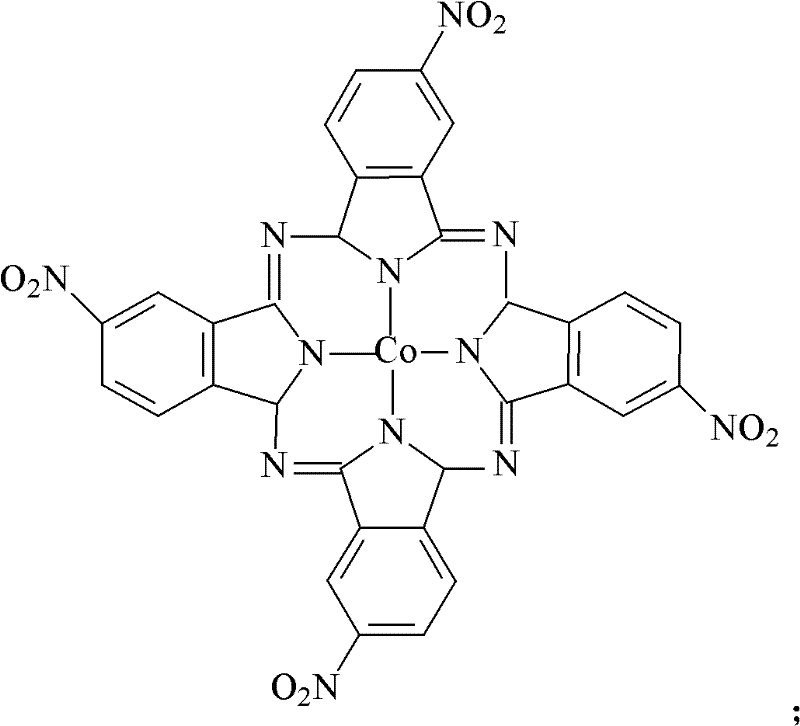

[0024] In the first step, mix 8.2g of 4-nitrophthalic anhydride, 0.05g of ammonium molybdate as the solute and 10g of urea, put them into a beaker, heat and start to melt, and after they are all melted, grind 1.2g Sprinkle cobalt chloride hexahydrate powder into the beaker, and keep stirring with a glass rod, slowly start heating to 140°C in an oil bath and continue for a period of time, then heat at a constant temperature of 160°C, during the heating process, the green substance continuously emits bubbles, and The volume expands rapidly until no more bubbles are generated, cool to room temperature, and then crush the solid, respectively boil it with 200mL1mol / L hydrochloric acid and 200mL1mol / L sodium hydroxide solution for one hour, cool and filter, and dissolve with water after each filtration The product is washed to neutral, and dried in the air to obtain a green solid substance,...

Embodiment 2

[0034] A preparation method of a novel photocatalytic sensitizer, comprising the following steps,

[0035] In the first step, 8.5g of 4-nitrophthalic anhydride and 1.4g of cobalt chloride hexahydrate, 0.07g of ammonium molybdate as the solute, and 12g of urea after heating and melting as the solvent were used for template reaction at 160°C to obtain Tetranitrocobalt phthalocyanine;

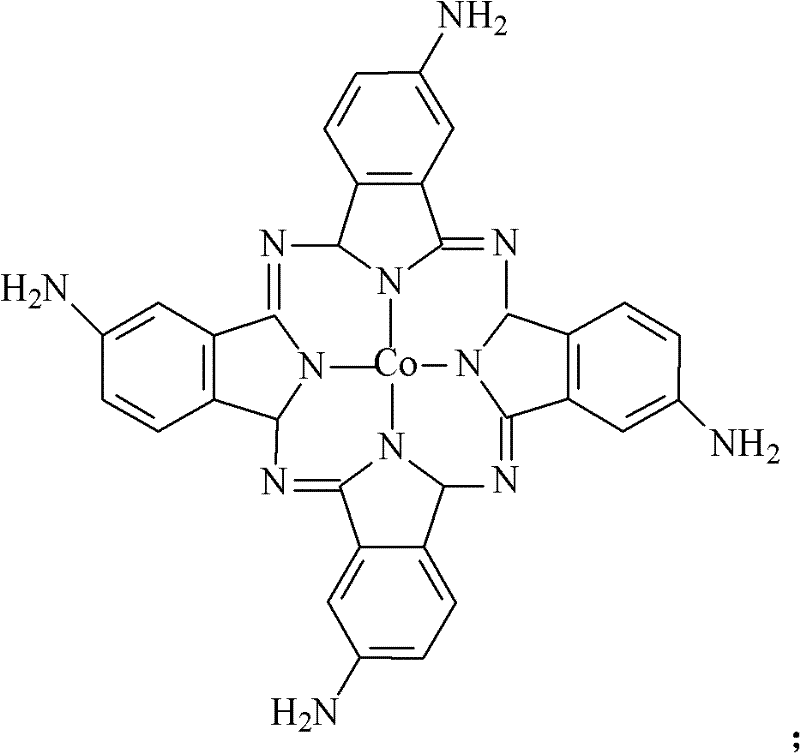

[0036] In the second step, reducing the tetranitrocobalt phthalocyanine with 5.96g sodium sulfide nonahydrate in 35mL of dimethylformamide solution with a mass concentration of 70.5% to obtain tetraaminocobalt phthalocyanine;

[0037] In the third step, 1.0 g of tetraaminocobalt phthalocyanine prepared in the second step is added to 150 mL of dimethylformamide solution with a mass concentration of 71%, and fully dissolved, and 1.8 g of maleic anhydride is dissolved in another 20mL of dimethylformamide solution with a mass concentration of 70%, and then mix the two solutions for reaction, keep the...

Embodiment 3

[0041] A preparation method of a novel photocatalytic sensitizer, comprising the following steps,

[0042]In the first step, 8.0g of 4-nitrophthalic anhydride and 1.5g of cobalt chloride hexahydrate, 0.08g of ammonium molybdate as the solute, and 8g of urea after heating and melting as the solvent were used for template reaction at 160°C to obtain Tetranitrocobalt phthalocyanine;

[0043] In the second step, reducing the tetranitrocobalt phthalocyanine with 5g sodium sulfide nonahydrate in 25mL of 80% dimethylformamide solution to obtain tetraaminocobalt phthalocyanine;

[0044] In the third step, the tetraaminocobalt phthalocyanine prepared in the second step of 0.76g is added to 134mL of dimethylformamide solution with a mass concentration of 70%, and fully dissolved, and 1.6g of maleic anhydride is dissolved in another 17mL of dimethylformamide solution with a mass concentration of 82.5%, then mix the two solutions for reaction, keep the reaction temperature at 60°C, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com