B-P-Zn-Si series density board flame-retardant mildew-proof agent and application thereof

A technology of b-p-zn-si and density board, which is applied in the field of chemical materials, can solve the problems that inorganic flame retardants are difficult to achieve flame retardant effects, and achieve the effects of ensuring mildew resistance, improving dispersion uniformity, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1, a kind of B-P-Zn-Sb-Si series density board flame retardant antifungal agent, raw material components are as follows:

[0056] Sodium borate (Na 2 B 4 o 7 10H 2 O): 60 kg;

[0057] Ammonium polyphosphate ((NH 4 PO 3 ) n ): 66 kg;

[0058] Zinc borate (2ZnO·3B 2 o 3 3.5H 2 O): 60 kg;

[0059] 40% ethanol solution of organic silicon quaternary ammonium salt: 35 kg, wherein the content of organic silicon quaternary ammonium salt is 14 kg.

[0060] Preparation method, the steps are as follows:

[0061] Dry sodium borate at 60-70°C for 6 hours, then mix it with 40wt% ethanol solution of organosilicon quaternary ammonium salt, stir for 20 minutes to make it evenly mixed, let it stand for 12 hours, then add ammonium polyphosphate and zinc borate respectively, Stir for 30min, that is.

[0062] The application of the MDF flame retardant antifungal agent of the present embodiment:

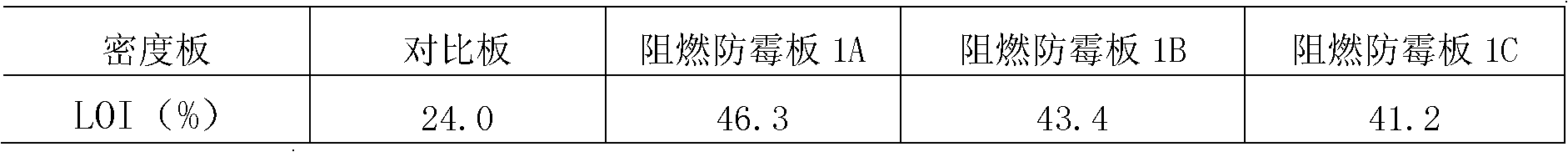

[0063] Utilize the density board flame retardant antifungal agent of ...

Embodiment 2

[0070] Embodiment 2, B-P-Zn-Sb-Si series density board flame retardant antifungal agent

[0071] As described in Example 1, the difference is that the raw material components are as follows:

[0072] Sodium borate (Na 2 B 4 o 7 10H 2 O): 70 kg;

[0073] Ammonium polyphosphate ((NH 4 PO 3 ) n ): 60 kg;

[0074] Zinc borate (2ZnO·3B 2 o 3 3.5H 2 O): 56 kg;

[0075] 40% ethanol solution of organic silicon quaternary ammonium salt: 35 kg, that is, 14 kg of pure organic silicon quaternary ammonium salt.

[0076] The preparation method is the same as in Example 1.

[0077] The application of the MDF flame retardant antifungal agent of the present embodiment:

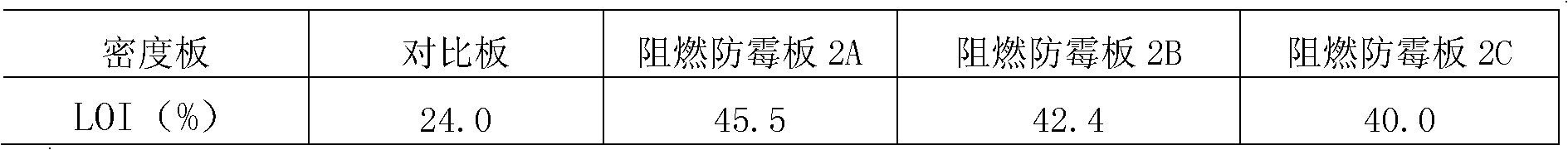

[0078] Use the density board flame retardant antimold agent of this embodiment to prepare flame retardant antimold density boards 2A, 2B, 2C, the preparation method is as described in the density board preparation of embodiment 1, the difference is that 200 kg of embodiment 2 The obtained flame retardant and ant...

Embodiment 3

[0085] The B-P-Zn-Si series density board flame retardant antifungal agent as described in Example 1, the difference is that the raw material components are as follows:

[0086] Sodium borate (Na 2 B 4 o 7 10H2 O): 80 kg;

[0087] Ammonium polyphosphate ((NH 4 PO 3 ) n ): 70 kg;

[0088] Zinc borate (2ZnO·3B 2 o 3 3.5H 2 O): 36 kg;

[0089] Organosilicon quaternary ammonium salt [(CH 3 CH 2 O) 3 Si(CH 2 ) 3 N(CH 3 ) 2 (C 18 h 37 )] + Cl - , 40% ethanol solution: 35 kg, that is, pure organic silicon quaternary ammonium salt: 14 kg.

[0090] The preparation method is the same as in Example 1.

[0091] The application of the MDF flame retardant antifungal agent of the present embodiment:

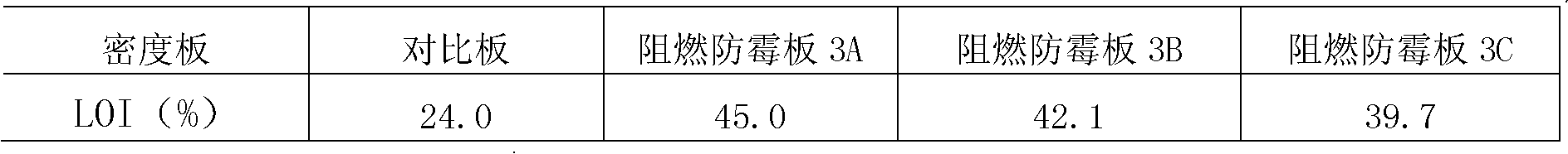

[0092] Utilize the density board flame retardant antimold agent of this embodiment to prepare flame retardant antimold density board 3A, 3B, 3C, the preparation method of flame retardant antimold density board is as described in Example 1, the difference is that 200 kg 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com