Transparent heat-insulation polyvinyl alcohol poly-butyraldehyde nanocomposite and preparation method thereof

A technology of polyvinyl butyral and nano-composite materials, which is applied in automotive safety glass, construction, in-situ dispersion and one-step synthesis of PVB nano-composite materials and its preparation, and can solve the problem of high price, low reflectivity and PVB nano-composite Material research has not been reported, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

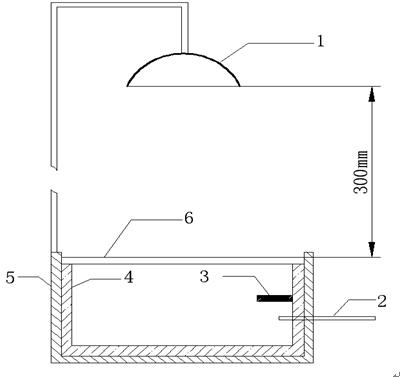

[0045] Step (1): Add 15g of PVA and 200g of distilled water into a four-necked flask equipped with a condenser, a thermometer and an electric stirrer, raise the temperature to 90°C to completely dissolve the PVA, and then cool to room temperature;

[0046] Step (2): Add 0.3g nanometer ITO, 0.006g γ-glycidyl etheroxypropyl trimethoxysilane, 0.048g dispersant 5040, 6g distilled water in turn in the beaker, and disperse under the action of 200kHz ultrasonic wave for 30min to obtain surface treatment The nano-ITO dispersion liquid that has passed. Add the nano-ITO dispersion into the four-necked flask of the PVA aqueous solution prepared in step (1), and then disperse under the action of ultrasonic waves for 60 minutes;

[0047] Step (3): Weigh 0.32g of sodium dodecylbenzene sulfonate and 11g of concentrated hydrochloric acid into the four-necked flask containing nano-ITO PVA aqueous solution in step (2), weigh 15g of n-butyraldehyde in constant pressure drop In the funnel, at ro...

Embodiment 2

[0050] Step (1): Add 10g of PVA and 200g of distilled water into a four-neck flask equipped with a condenser, a thermometer and an electric stirrer, raise the temperature to 90°C to completely dissolve the PVA, and then cool to room temperature;

[0051] Step (2): Add 0.20g of nano-ITO, 0.004g of γ-glycidyl etheroxypropyl trimethoxysilane, 0.032g of dispersant 5040, and 4g of distilled water in sequence in a beaker, and disperse for 30min under the action of 200kHz ultrasonic waves to obtain surface-treated nano ITO dispersion. Add the nano-ITO dispersion into the four-necked flask of the PVA aqueous solution prepared in step (1), and then disperse under the action of ultrasonic waves for 60 minutes;

[0052] Step (3): Weigh 0.32g of sodium dodecylbenzene sulfonate and 0.55g of concentrated hydrochloric acid into the four-necked flask containing the PVA aqueous solution of nano-ITO in step (2), weigh 6g of n-butyraldehyde in constant pressure drops In the liquid funnel, at ro...

Embodiment 3

[0055] Step (1): Add 5g of PVA and 100g of distilled water into a four-neck flask equipped with a condenser, a thermometer and an electric stirrer, raise the temperature to 90°C to completely dissolve the PVA, and then cool to room temperature;

[0056] Step (2): Add 0.20g of nano-ITO, 0.004g of γ-glycidyl etheroxypropyl trimethoxysilane, 0.032g of dispersant 5040, and 4g of distilled water in sequence in a beaker, and disperse for 30min under the action of 200kHz ultrasonic waves to obtain surface-treated The nano-ITO dispersion liquid that has passed. Add the nano-ITO dispersion into the four-necked flask of the PVA aqueous solution prepared in step (1), and then disperse under the action of ultrasonic waves for 60 minutes;

[0057] Step (3): Weigh 0.16g of sodium dodecylbenzene sulfonate and 0.55g of concentrated hydrochloric acid into the four-necked flask of PVA aqueous solution containing nano-ITO in step (2), weigh 2.5g of n-butyraldehyde under constant pressure In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com