Silver-base rare-earth alloy material and preparation method and application thereof

A rare earth alloy and silver-based technology, which is applied to silver-based rare earth alloy materials and their preparation and application fields, can solve the problems of decreased material elongation, unfavorable material processing, shortened life and the like, achieves good elongation, is conducive to cold working deformation, and is good for Effects of high temperature wear resistance and arc resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

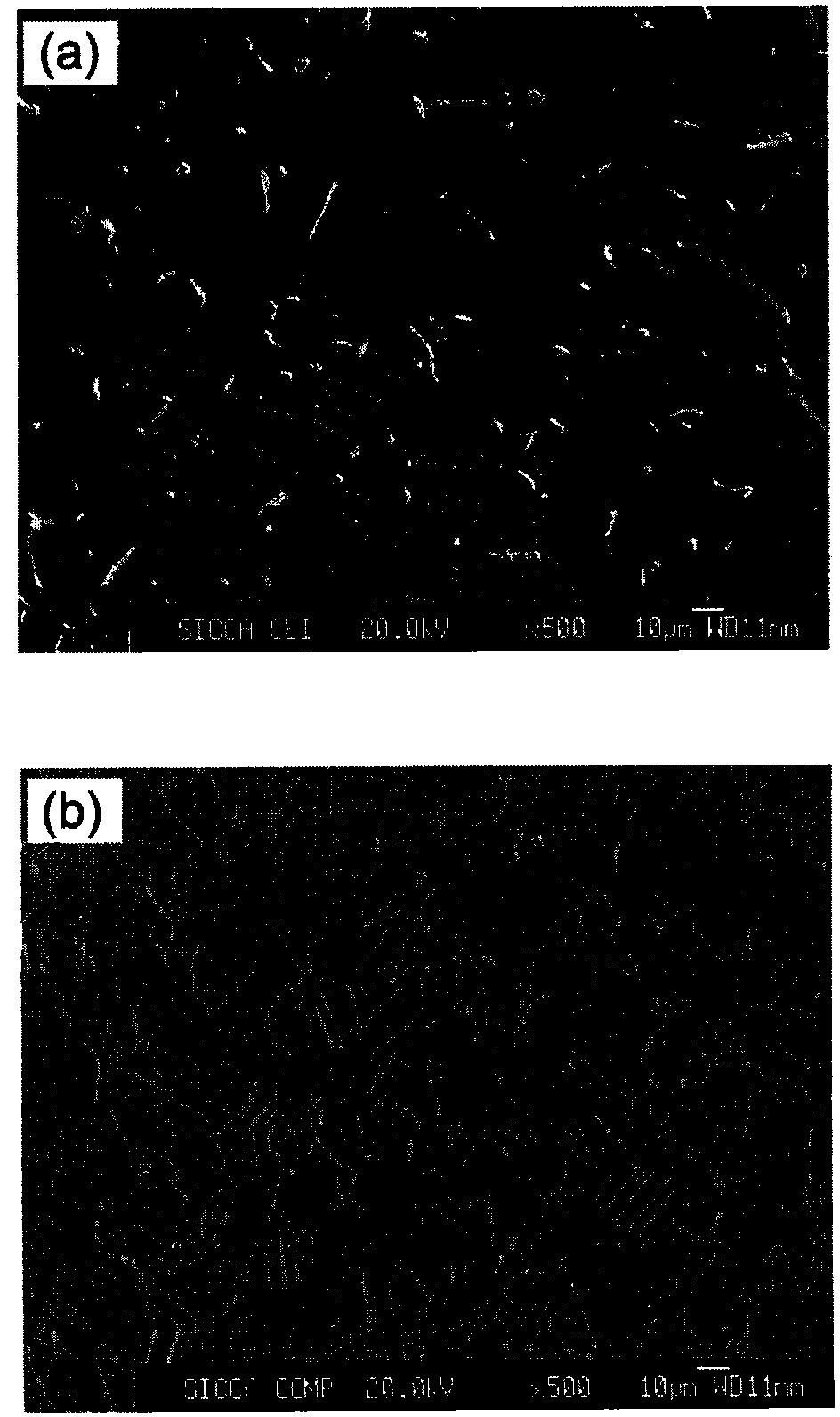

Image

Examples

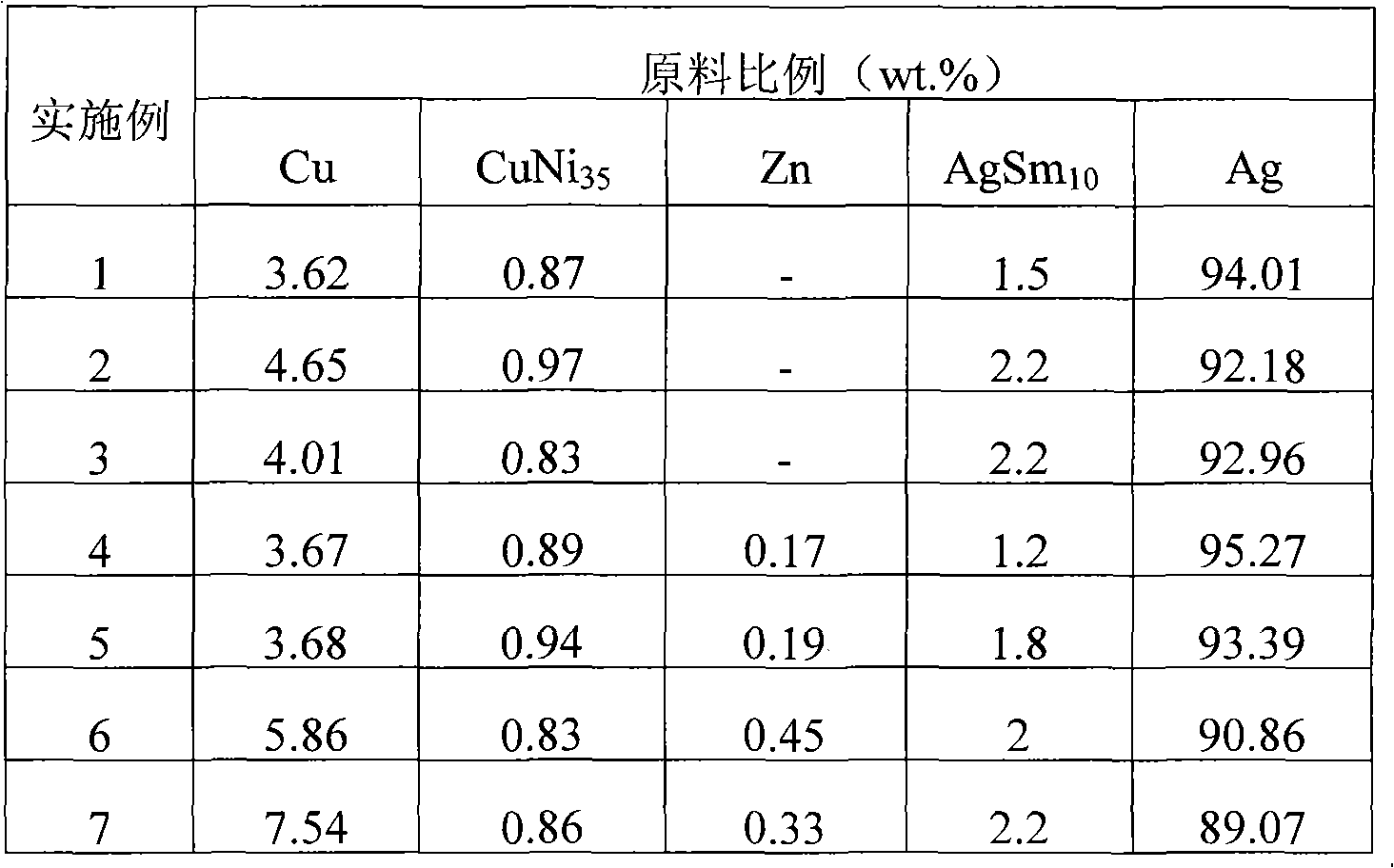

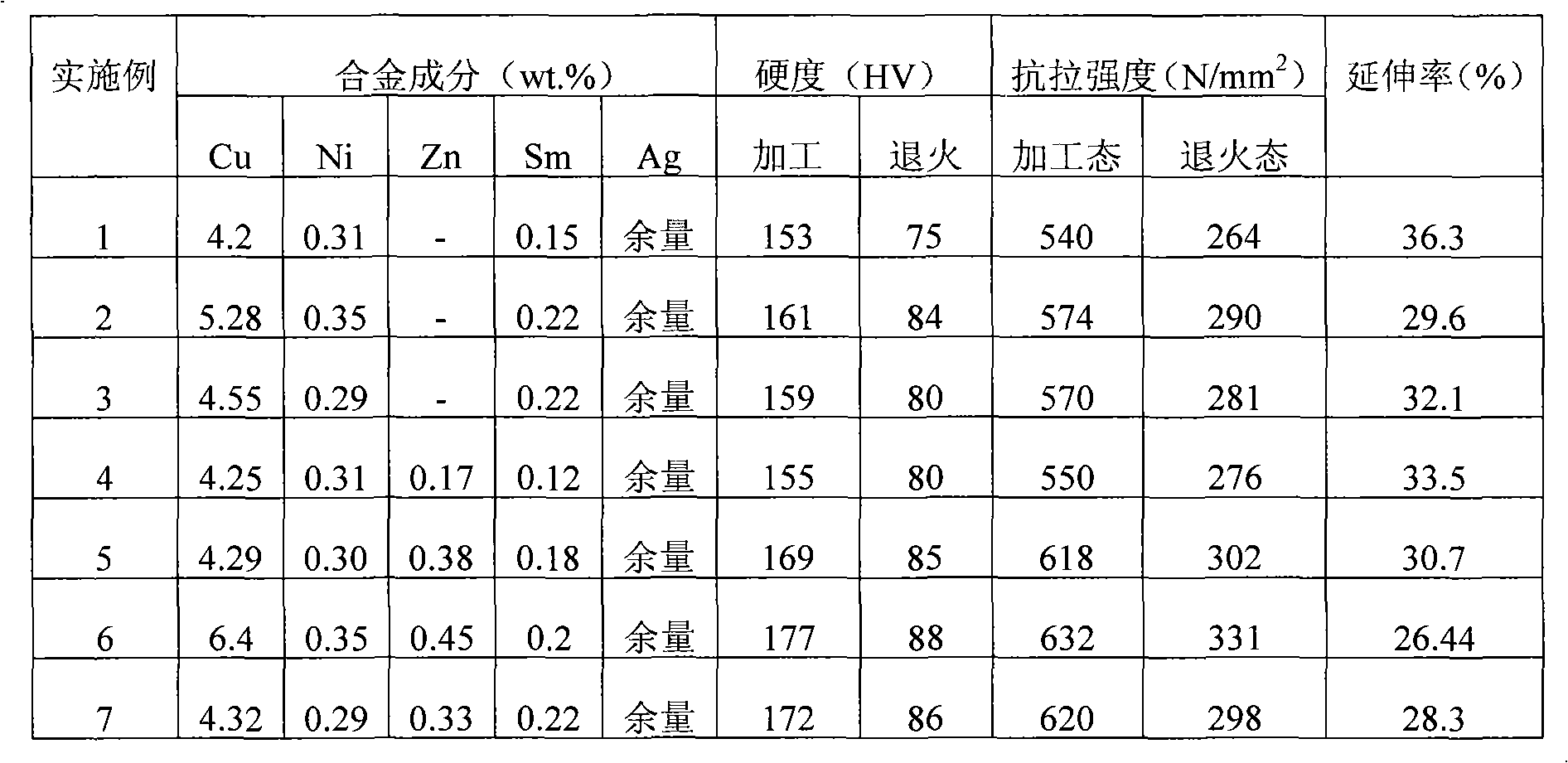

Embodiment 1~7

[0049] The preparation method of embodiment 1~7 silver-based rare earth alloy material

[0050] By mass percentage (%): pure Ag, oxygen-free copper (Cu), pure Zn, CuNi 35 and AgSm 10 Alloy is raw material, carries out following operation according to the prescription in each embodiment in table 1 (calculate with ingot being 50Kg): 1. metal raw material is smelted under anaerobic condition and argon protection and casts to obtain ingot; 2. this Homogenize the ingot at 760°C for 3 hours; ③Grind the surface of the ingot with a grinder to achieve surface treatment; ④Cold rolling to make the pre-deformation of the ingot in the thickness direction 45%; ⑤At 650°C, decompose Annealing under protective atmosphere for 2 hours; ⑥ intermediate rolling; ⑦ under nitrogen and hydrogen atmosphere, protected annealing at 700°C for 15 minutes in a continuous heat furnace; finish rolling to obtain a silver-based rare earth alloy material, and the contents of each component are shown in Table 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com