Zinc electrode of zinc-air battery

A zinc-air battery and zinc electrode technology, applied in battery electrodes, active material electrodes, circuits, etc., can solve the problems of battery capacity attenuation, poor electrical performance, and unsatisfactory effects, so as to improve discharge performance and facilitate the diffusion of ions , Inhibit the effect of passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

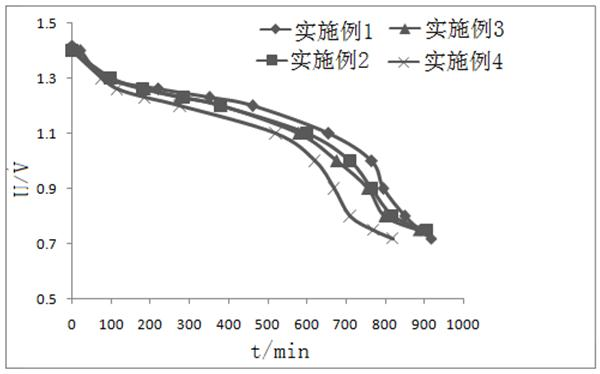

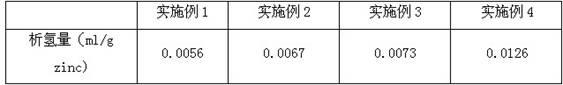

Examples

Embodiment 1

[0019] The zinc electrode is made by mixing and stirring zinc powder, binder, electrolyte and microcrystalline cellulose according to the proportion parameters in parts by weight. The parts by weight of each component are zinc powder 50, binder 3.5, electrolyte 60, micro Crystalline cellulose 0.35.

[0020] KOH content 50g, tetraalkylammonium hydroxide 1.0g, sodium dodecylbenzenesulfonate 2.0g, Zn compound 0.9g, K 2 CO 3 12g, the balance is distilled water.

Embodiment 2

[0022] The zinc electrode is made by mixing and stirring zinc powder, binder, electrolyte and microcrystalline cellulose according to the proportion parameters in parts by weight. The parts by weight of each component are zinc powder 50, binder 3.5, electrolyte 60, micro Crystalline cellulose 0.35.

[0023] KOH content 50g, tetraalkylammonium hydroxide 0.3g, sodium dodecylbenzenesulfonate 0.5g, Zn compound 0.9g, K 2 CO 3 12g, the balance is distilled water.

Embodiment 3

[0025] The zinc electrode is made by mixing and stirring zinc powder, binder, electrolyte and microcrystalline cellulose according to the proportion parameters in parts by weight. The parts by weight of each component are zinc powder 50, binder 3.5, electrolyte 60, micro Crystalline cellulose 0.35.

[0026] KOH content 50g, tetraalkylammonium hydroxide 1.5g, sodium dodecylbenzenesulfonate 2.5g, Zn compound 0.9g, K 2 CO 3 12g, the balance is distilled water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com