Pretreatment method for high-acid inferior crude oil processing wastewater

A crude oil processing and acid-degraded technology, which is applied to the treatment field of wastewater discharged from an electric desalination device during the processing of high-acid and poor-quality crude oil, can solve the problems of inability to meet the expected purpose of reusing oily wastewater and salty wastewater to meet standards, and inability to effectively treat wastewater, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

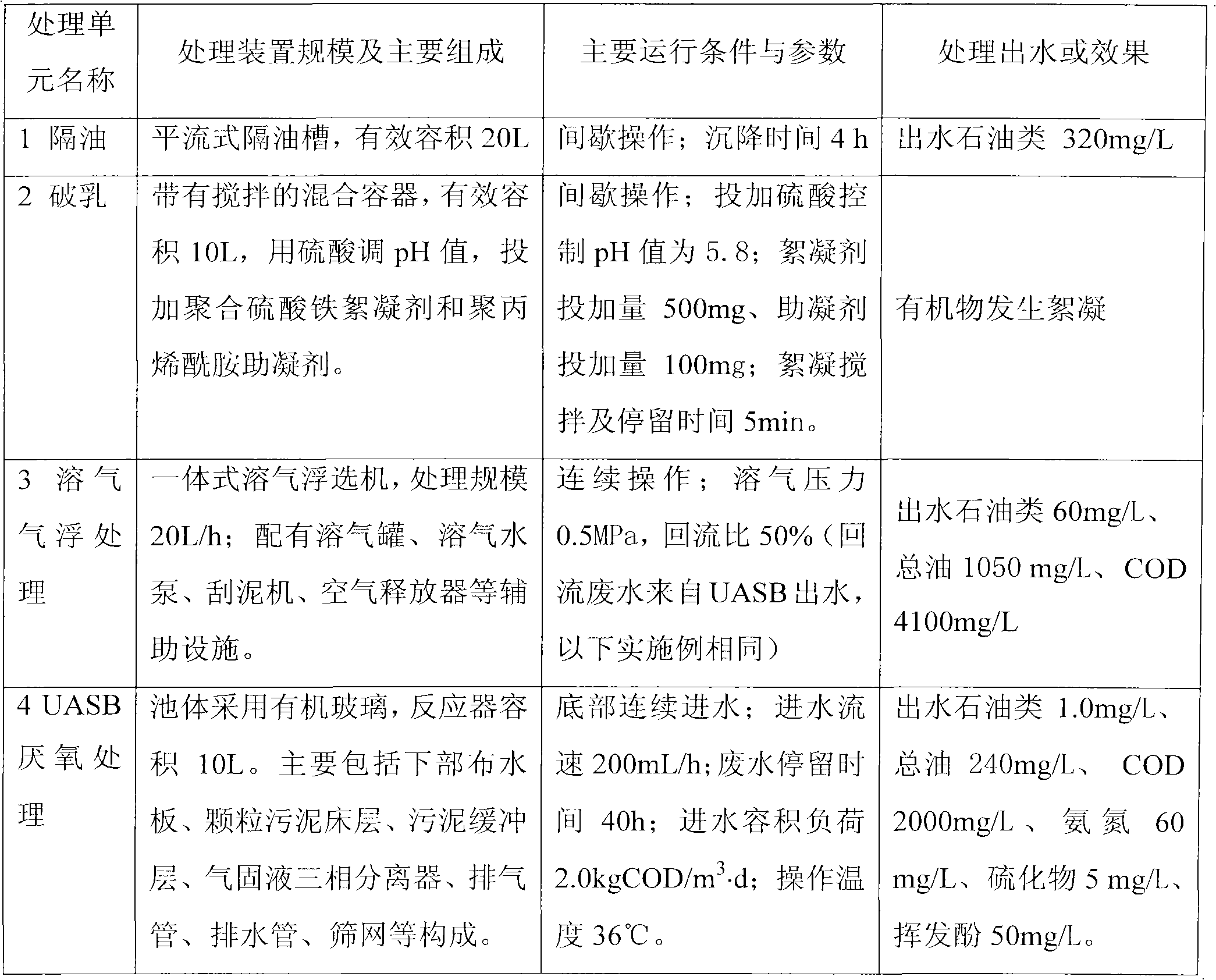

[0027] The treatment method of the present invention is used to treat the wastewater discharged from the electric desalting device of a domestic high-acid and low-quality crude oil refining and chemical enterprise. The main pollutants in wastewater are COD 5400mg / L (chromium method, the same below), petroleum 600mg / L, total oil 2000mg / L, ammonia nitrogen 60mg / L, volatile phenol 50mg / L, sulfide 10.0mg / L, pH 8.5 .

[0028] Adopt oil separation-acidification demulsification-dissolved air flotation-UASB-SBR-filtration combined process of the present invention to carry out laboratory treatment test on the above-mentioned wastewater, the wastewater treatment scale is 200mL / h, the main experimental devices of each treatment unit are composed and operated The conditions and treatment effects are shown in Table 1. After being treated by the method of the present invention, the COD in the electric desalination wastewater can be reduced to below 300 mg / L, the petroleum can be reduced to...

Embodiment 2~3

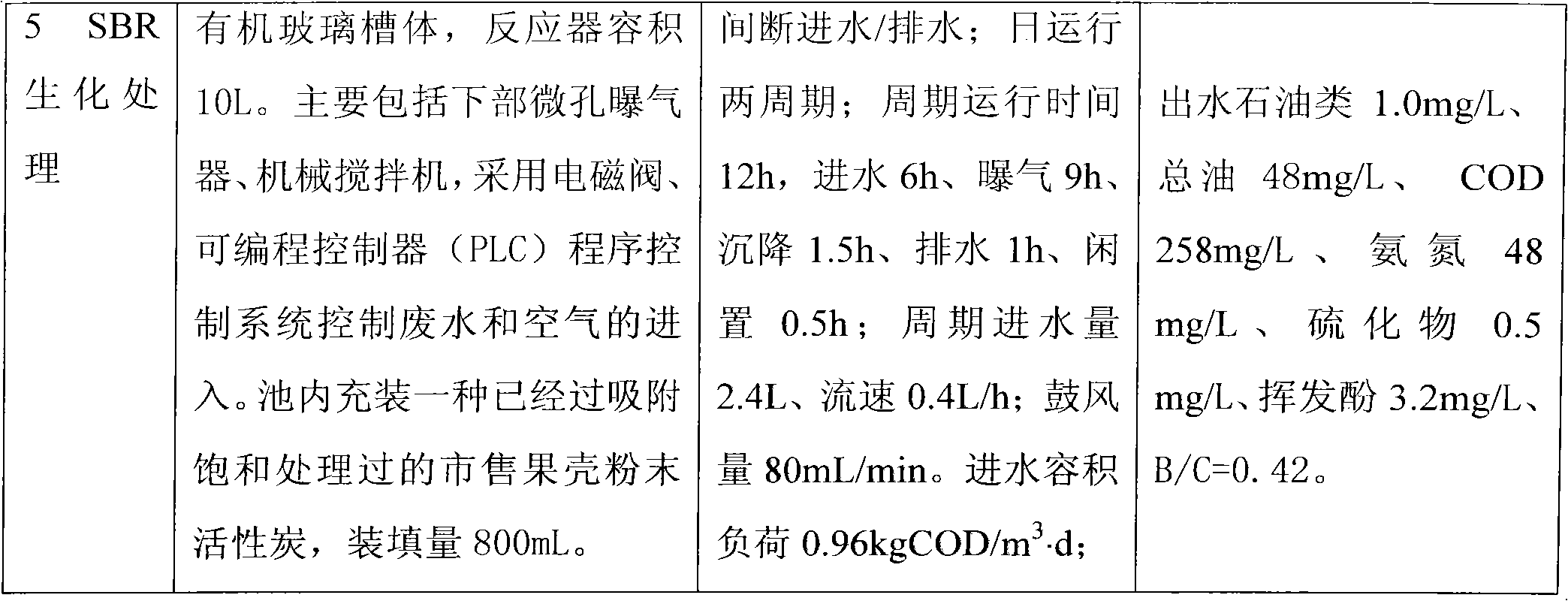

[0035] Using the treatment device of Example 1 to treat the same sewage as in Example 1, the wastewater treatment effects obtained by changing the operating conditions of each treatment unit are shown in Table 2 and Table 3, respectively.

[0036] Main processing unit constitution and processing effect of table 2 embodiment 2

[0037]

[0038]

[0039] Main processing unit composition and processing effect of table 3 embodiment 3

[0040]

[0041]

Embodiment 4

[0043] The treated effluent of Example 1 is sent continuously to the sewage treatment plant, the displacement accounts for 30% of the treated water volume of the sewage treatment plant, the sewage treatment plant can operate normally and stably, and the drainage of the sewage treatment plant can reach the discharge standard (COD value is lower than 60mg / L) .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com