Method for preparing cyclohexenyl cyclohexanone with high conversion rate

A technology of cyclohexanone and catalyst, which is applied in the field of preparation of cyclohexenyl cyclohexanone, can solve the problems of environmental pollution, low single-pass conversion rate of cyclohexanone, etc., and achieve the effect of reducing waste water discharge and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

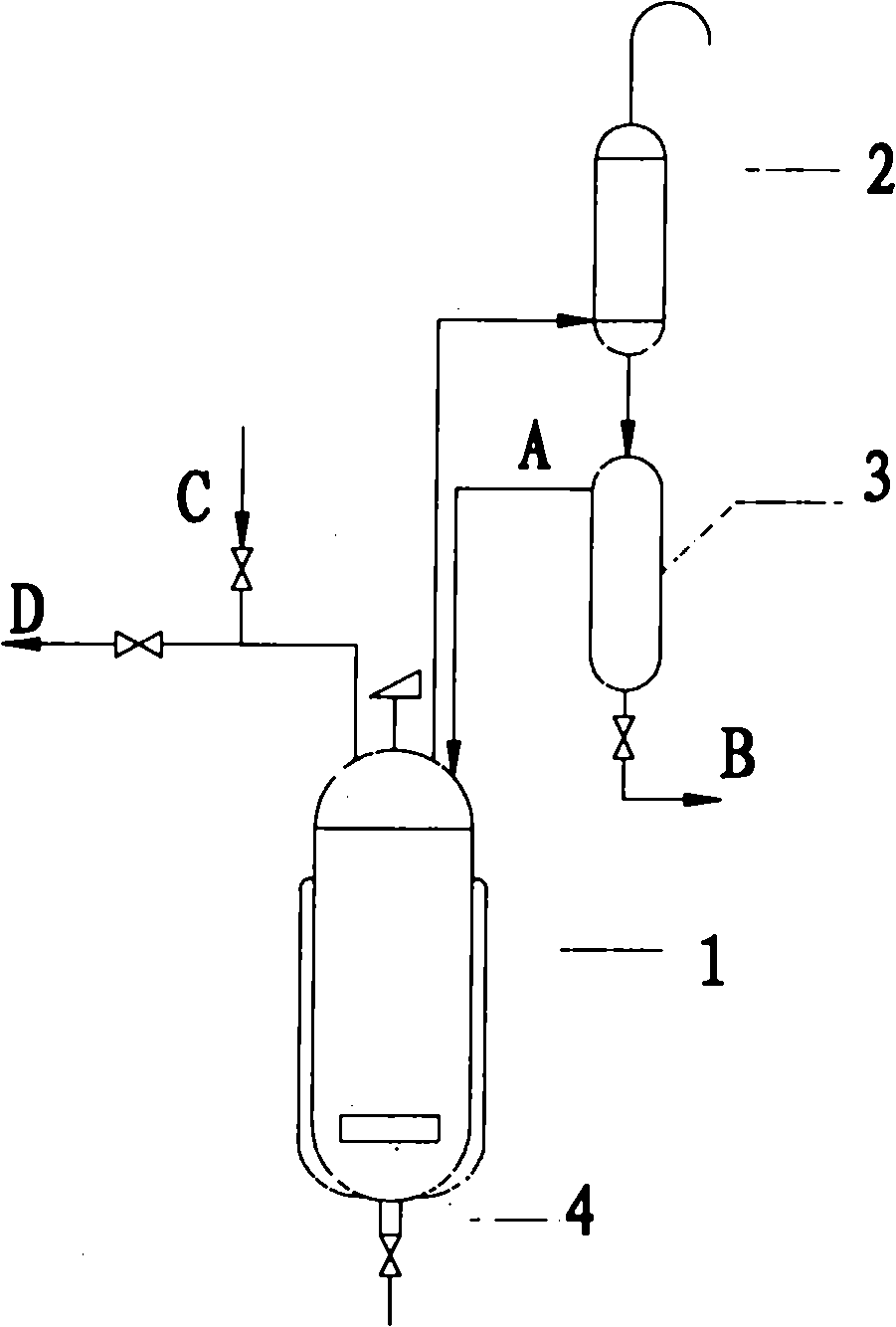

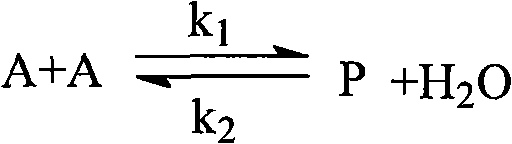

[0025] In the reaction device shown in Figure 1, the cyclohexanone condensation reactor is 1000 L, the stirring is paddle type, and the rotation speed is 130 rpm. The catalyst filter device is a metal sintered filter tube with a diameter of Φ50 mm and a length of 200 mm. Add 700kg of cyclohexanone into the 1000L reactor, and add 120 mesh γ-Al under stirring 2 o 3 Catalyst 20kg, close the feeding port, heat the jacket with circulating heat transfer oil at 250°C, feed circulating cooling water into the total reflux condenser, and react under normal pressure. When the temperature of the kettle rises above 80°C, the condensation reaction of cyclohexanone begins, and the water and cyclohexanone vapor generated by the reaction rise to the total reflux condenser to condense, and then are collected in the oil-water separator for phase separation, and the water is kept at the bottom of the separator intermittently. Or discharge continuously, and the upper oil phase returns to the reac...

Embodiment 2

[0028] Same device as in Example 1, add 600kg of cyclohexanone in the reactor, and add 120 mesh γ-Al under stirring 2 o 3 20kg of catalyst, 100kg of cyclohexane with water agent, the maximum reaction temperature is 140°C, and other conditions are the same.

[0029] Stop heating after reaction finishes, sampling adopts gas chromatographic analysis condensation product to form: cyclohexanone 26.5%, cyclohexenyl cyclohexanone 72.0%, polycondensation compound is 1.5% (does not comprise cyclohexanone), cyclohexanone one-way The conversion rate is about 75%, the reaction selectivity is above 97.0%, and the purity of the cyclohexenyl cyclohexanone after direct distillation of the condensation product reaches 99.6%.

Embodiment 3

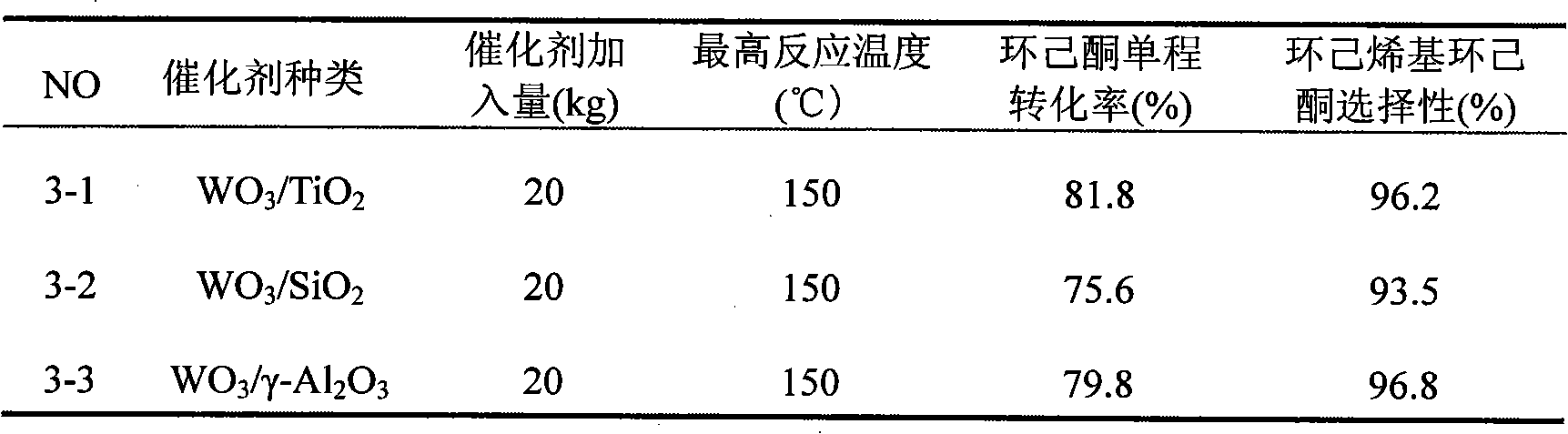

[0031] Same device as in Example 1, add 700kg of cyclohexanone in the reactor, and add 120 mesh WO 3 / TiO 2 、WO 3 / SiO 2 、WO 3 / γ-Al 2 o 3 Catalyst 20kg, other conditions are all the same, and its reaction result is shown in the following table.

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com