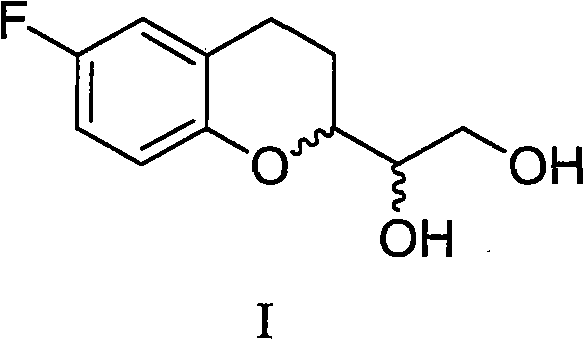

Preparation method for benzodihydropyran compound

A compound, sodium borohydride technology, applied in the direction of organic chemistry, can solve the problems of harsh reaction conditions, large environmental pollution, long synthesis steps, etc., and achieve the effect of short reaction steps, simple post-treatment, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

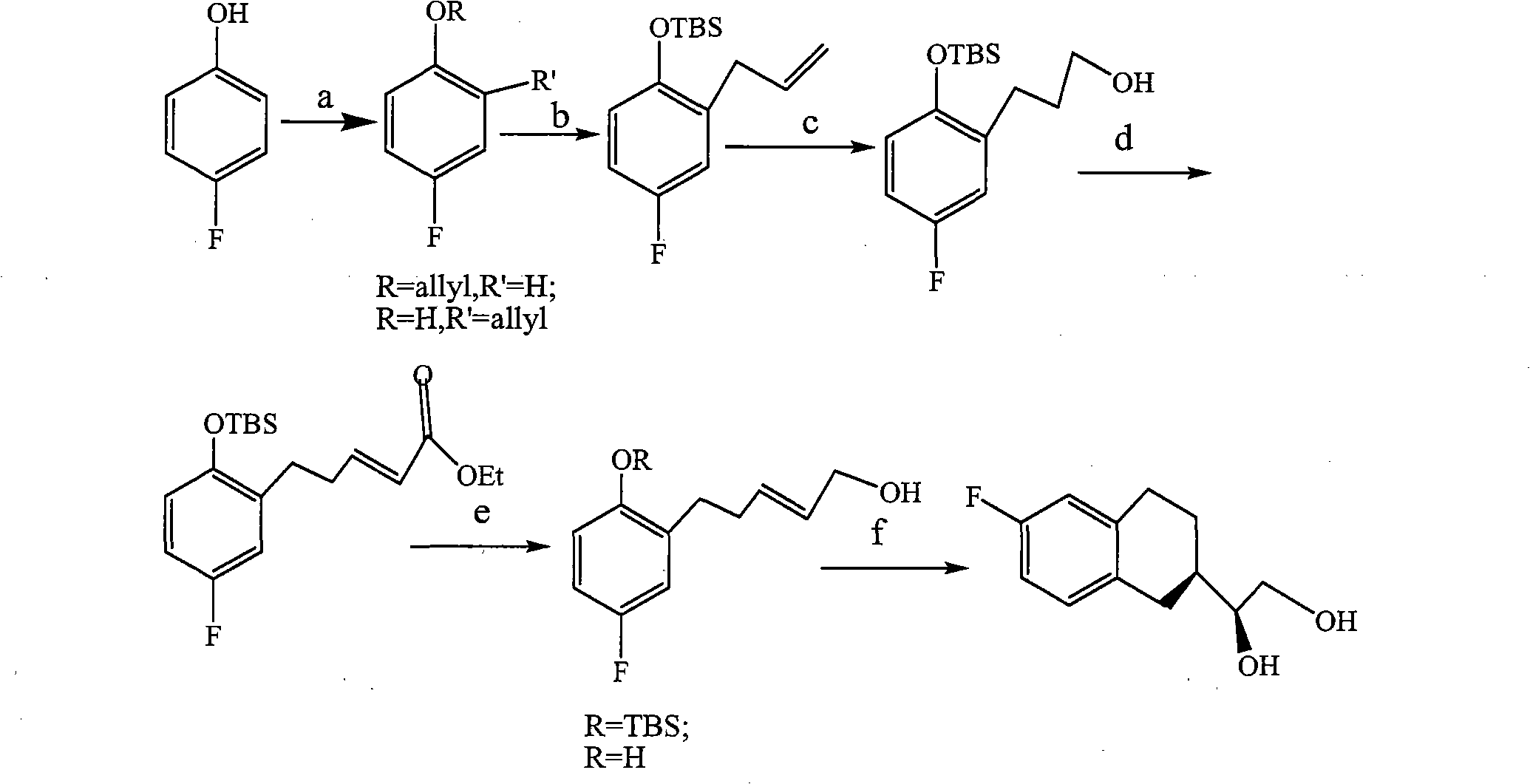

Method used

Image

Examples

Embodiment 1

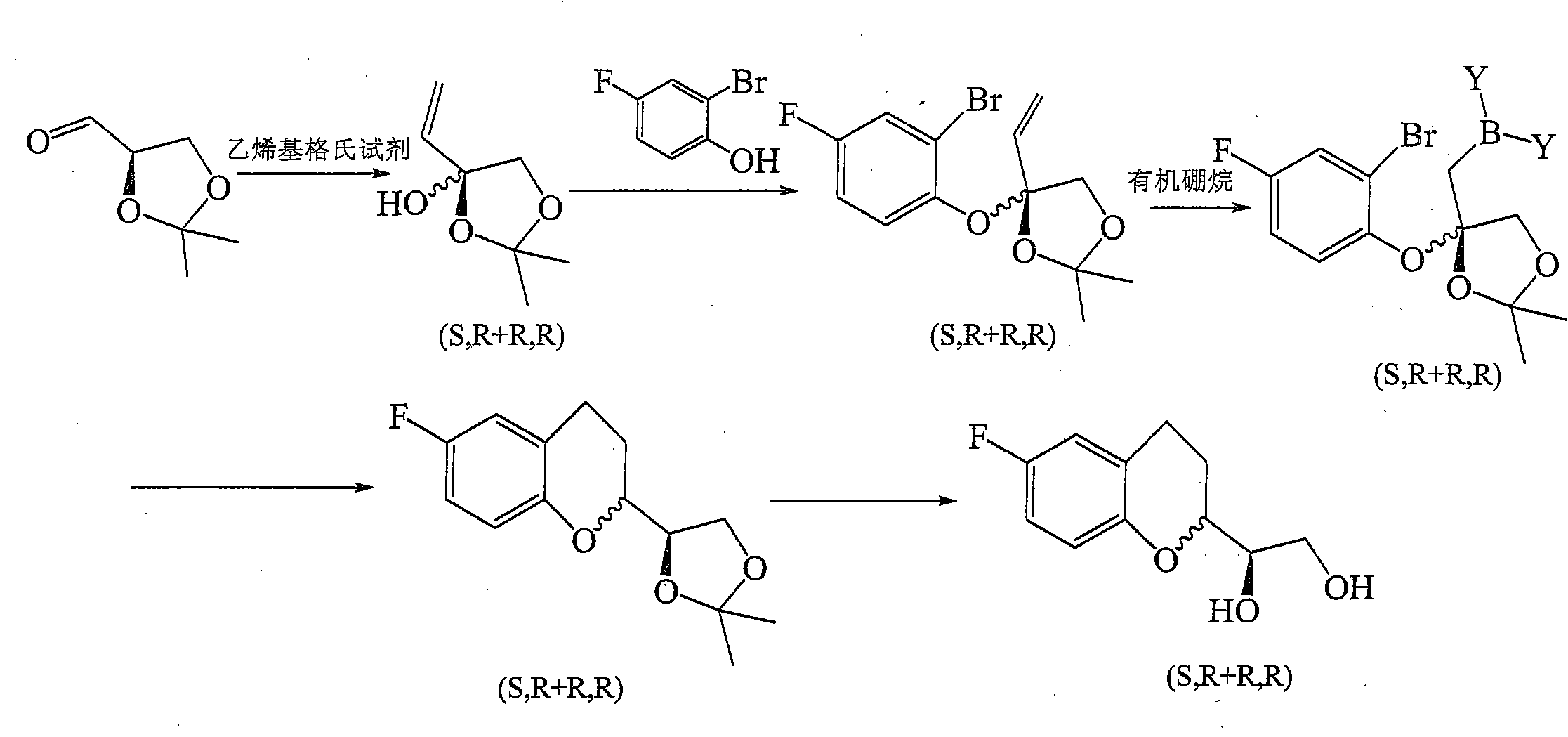

[0049] 1, the synthesis of formula IIa compound

[0050]

[0051] 1.1 Dissolve 5-fluoro-2-hydroxyacetophenone (30g, 0.195mol) in 500ml of dry tetrahydrofuran, cool in an ice-water bath at 0°C, add potassium tert-butoxide (23.76g, 0.195mol) under vigorous stirring, and stir vigorously After 30 minutes, a solution of D-glyceraldehyde acetonide in dichloromethane (w / w = 0.432, 70.36 g, 0.234 mol) was added. After stirring at 0°C for 3.5 hours, concentrated hydrochloric acid was added dropwise to adjust the pH value to 6, and the solvent was removed by rotary evaporation. Ethyl acetate (300 mL) and water (500 mL) were added to the residue, the organic phase was separated, washed with water and saturated brine, dried over anhydrous sodium sulfate, and spin-dried to obtain a yellow solid, which was recrystallized from absolute ethanol to obtain a light yellow powder Crystals (26 g, 47%).

[0052] 1.2 Referring to Example 1.1, potassium tert-butoxide was replaced by sodium tert-...

Embodiment 2

[0086] 1, the synthesis of formula IIb compound

[0087]

[0088] Dissolve 5-fluoro-2-hydroxyacetophenone (30 g, 0.195 mol) in 500 ml of dry tetrahydrofuran, cool in an ice-water bath at 0°C, add potassium tert-butoxide (23.76 g, 0.195 mol) under vigorous stirring, and stir vigorously for 30 After a few minutes, a solution of D-glyceraldehyde acetonide in dichloromethane (w / w = 0.432, 70.36 g, 0.234 mol) was added. After stirring at 0°C for 3.5 hours, concentrated hydrochloric acid was added dropwise to adjust the pH value to 6, and the solvent was removed by rotary evaporation. Ethyl acetate (300 mL) and water (500 mL) were added to the residue, the organic phase was separated, washed with water and saturated brine, dried over anhydrous sodium sulfate, and spin-dried to obtain a yellow solid, which was recrystallized from absolute ethanol to obtain a light yellow powder Crystals (23 g, 41.6%).

[0089] 2, the synthesis of formula IIIb compound

[0090]

[0091] Suspe...

Embodiment 3

[0113] The synthesis of embodiment three formula VIa compounds

[0114]

[0115] 1. Add oxalyl chloride (524 μL, 0.006 mol) into 30 mL of dry dichloromethane, add N,N-dimethylformamide (538 μL, 0.007 mol) dropwise, and stir at room temperature for 10 minutes. The compound of formula IVa (1 g, 0.004 mol) was added to the reaction liquid, triethylamine (1.67 mL, 0.012 mol) was added dropwise, the reaction was stopped after stirring overnight at room temperature, washed with water and saturated brine, dried and concentrated to obtain the product.

[0116] 2. Dissolve the compound of formula VIIa (0.6g, 2.40mmol) in 5mL of methanol, add palladium carbon (5%, 0.06g), after catalytic hydrogenation under normal pressure at 50°C for 1 hour, remove the palladium carbon by filtration, spin the filtrate to obtain colorless Oily product (0.59 g, 97.6%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com