Diesel hydrogenation method

A technology of diesel oil and process method, which is applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problem of high content of hydrogen sulfide, and achieve the effect of improving the quality of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

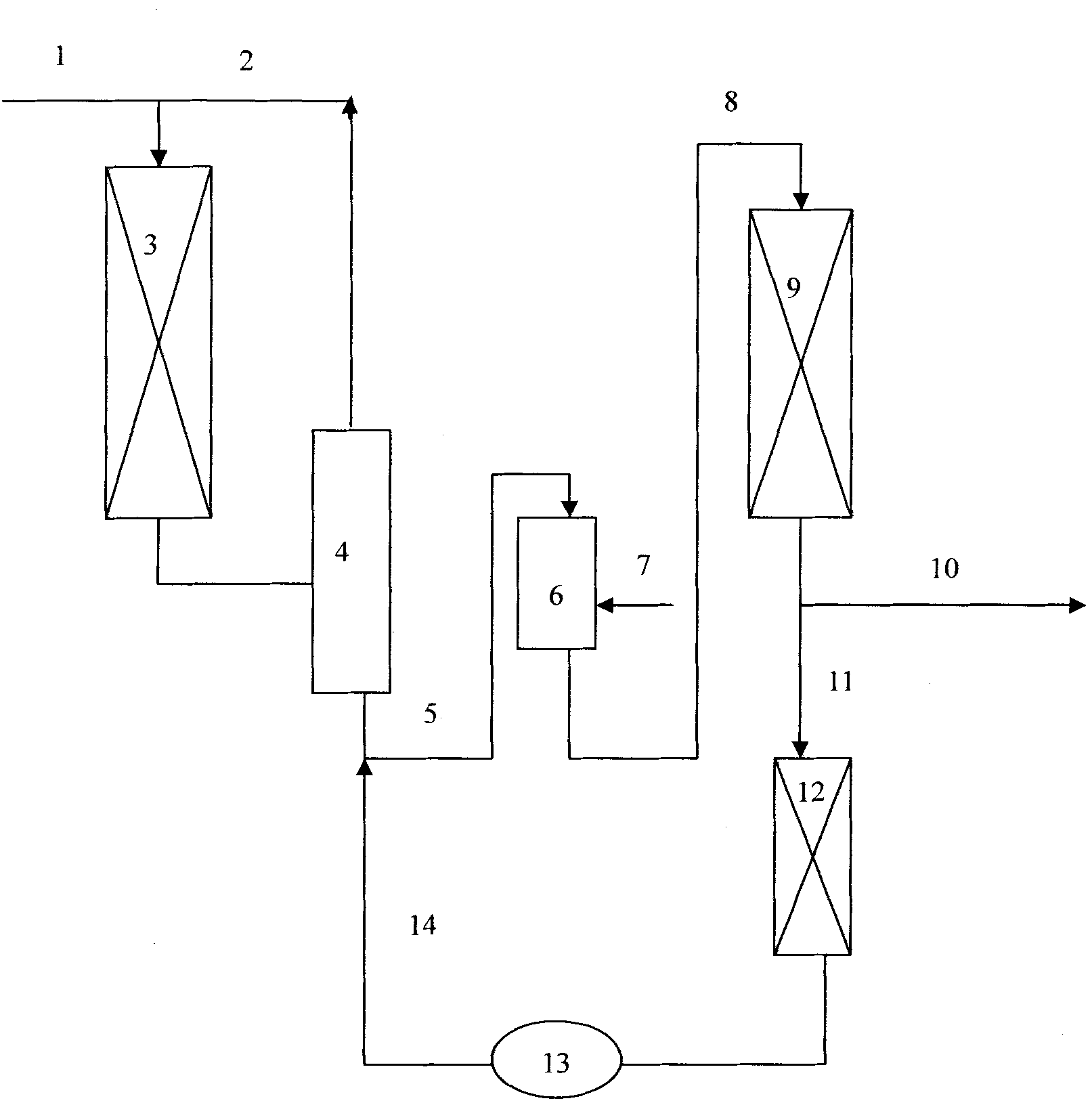

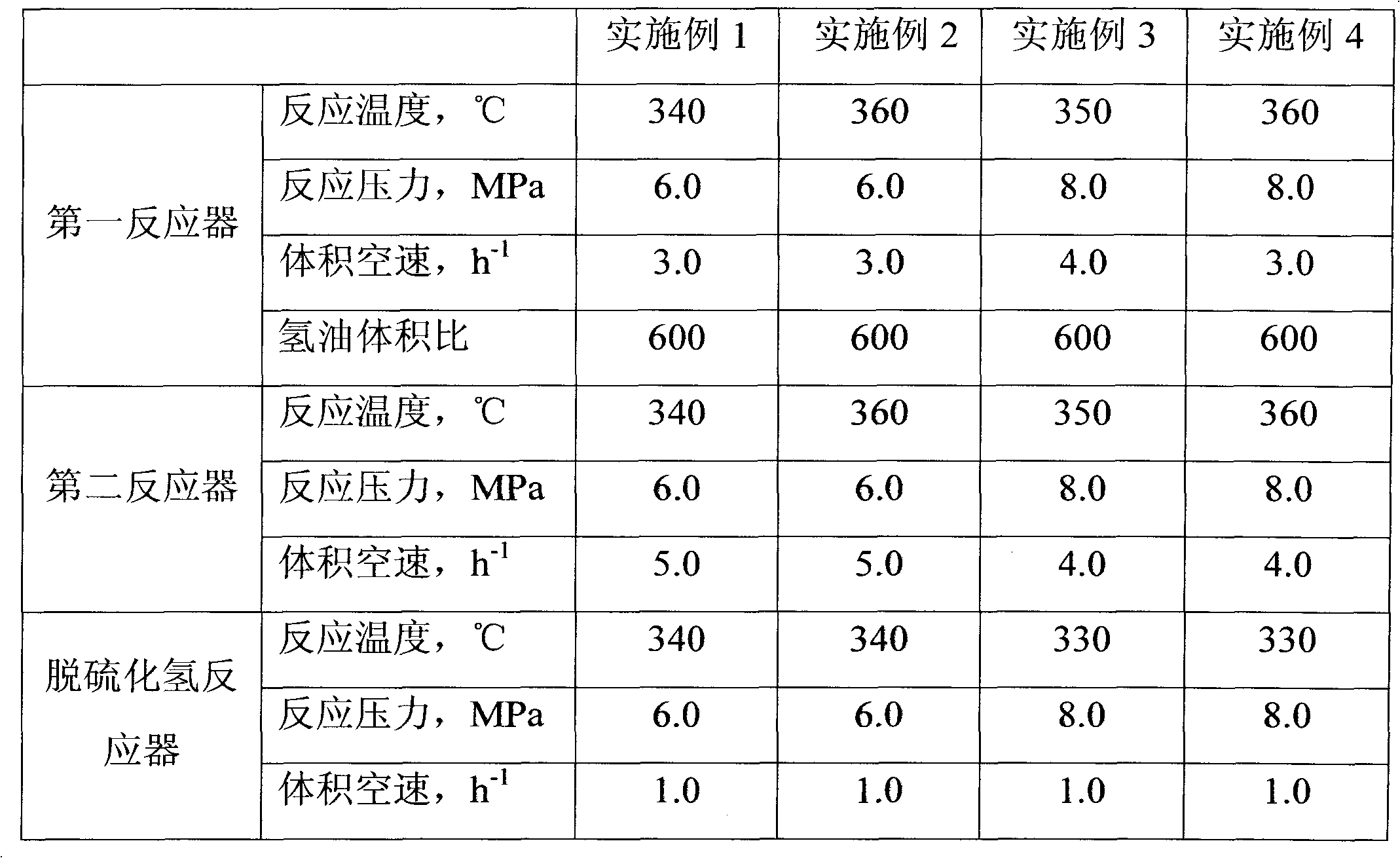

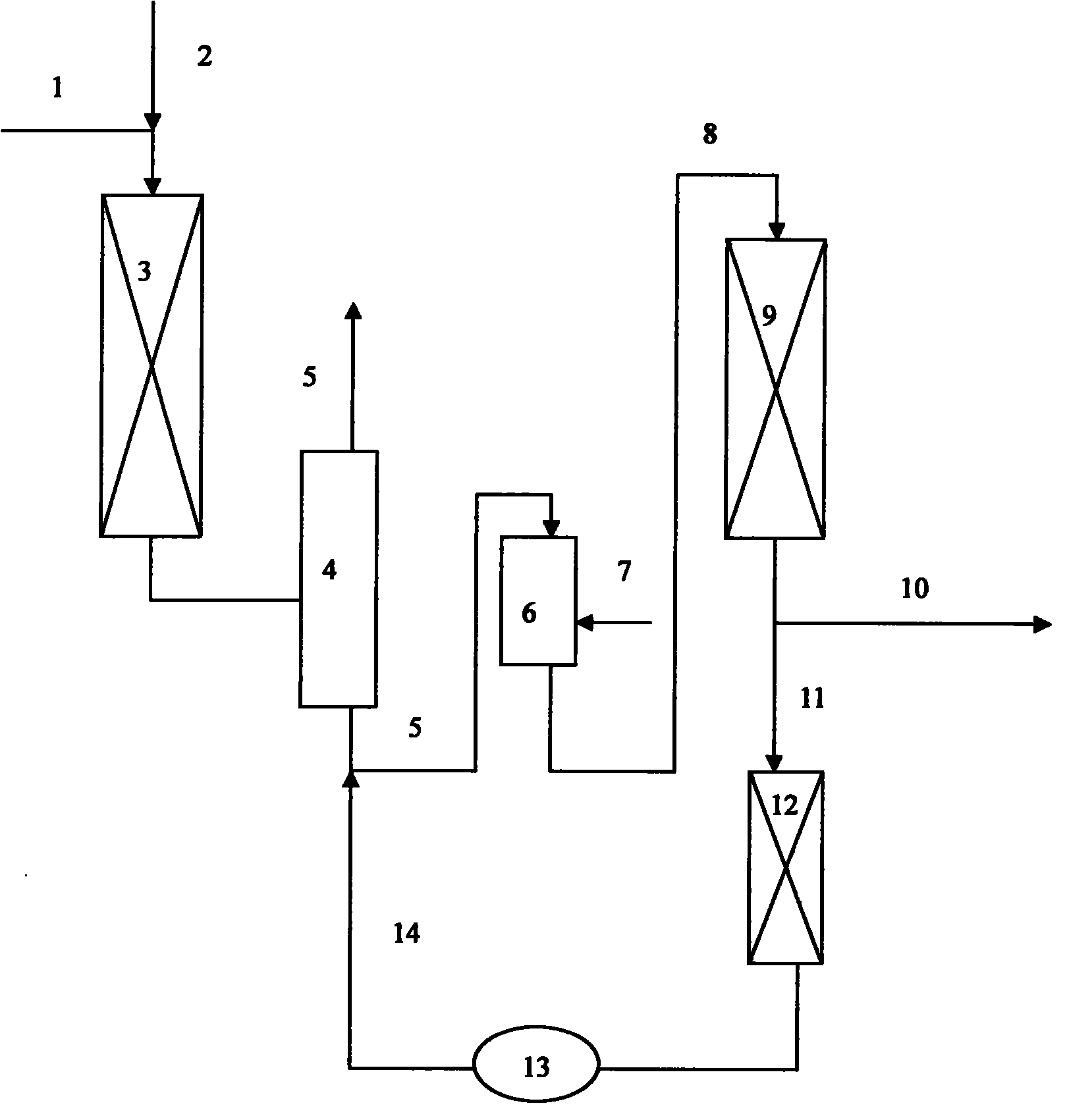

[0024] Adopt flow process of the present invention such as figure 1 . Nickel-tungsten-molybdenum type hydrorefining catalyst is used in the following examples. The composition and properties of the catalyst are shown in Table 1. The properties of the raw materials used are shown in Table 2. The process conditions used in Examples 1-4 are listed in Table 3. Examples 1-4 The evaluation results of 4 can be seen in Table 4.

[0025] Composition and main properties of the catalyst used in the embodiment of table 1

[0026] project

Catalyst A

Catalyst B

MoO 3

6.2

19.8

NiO

12.3

-

CoO

-

3.7

WO 3

15.2

-

carrier

Aluminum oxide

Aluminum oxide

Physical and chemical properties

Pore volume, ml / g

0.45

0.41

Specific surface area, m 2 / g

265

206

[0027] Table 2 Raw Oil Properties

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com