Forming method for semiconductor pipe core and conductive pillar

A technology of semiconductor tubes and conductive pillars, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc. The effect of sexual potency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments in the following description will disclose how to form and use semiconductor structures. However, it must be understood that these embodiments provide a variety of feasible inventive concepts and can be applied to a variety of specific contents. The specific embodiments are only used to illustrate specific ways of forming and using the embodiments, and are not used to limit the scope of the present invention.

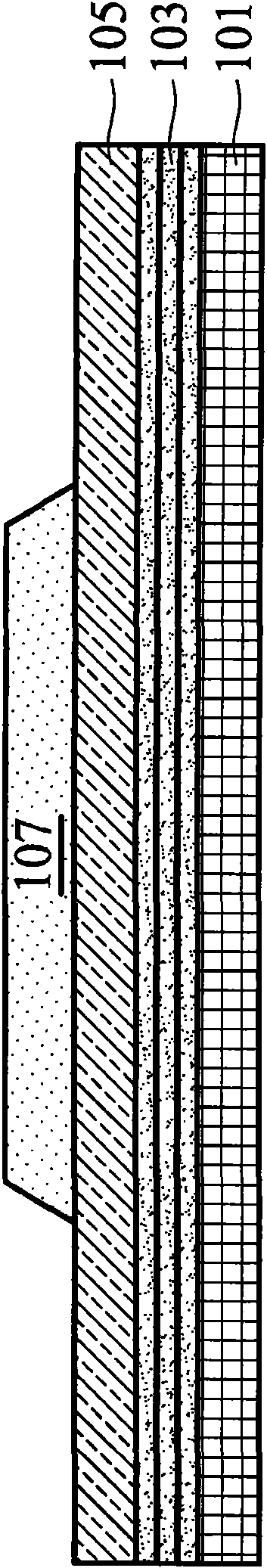

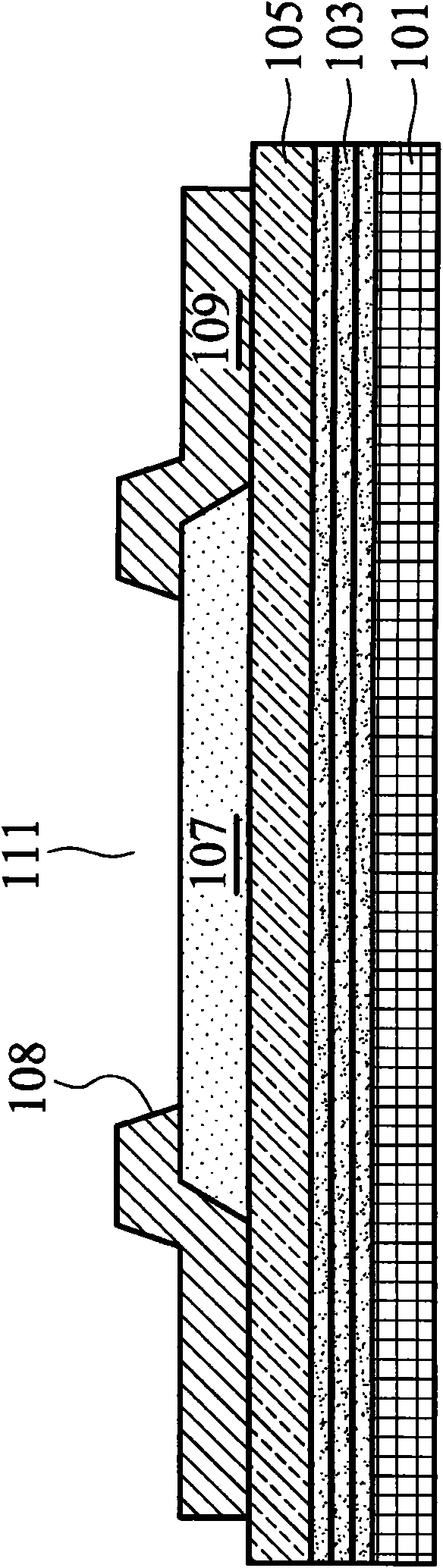

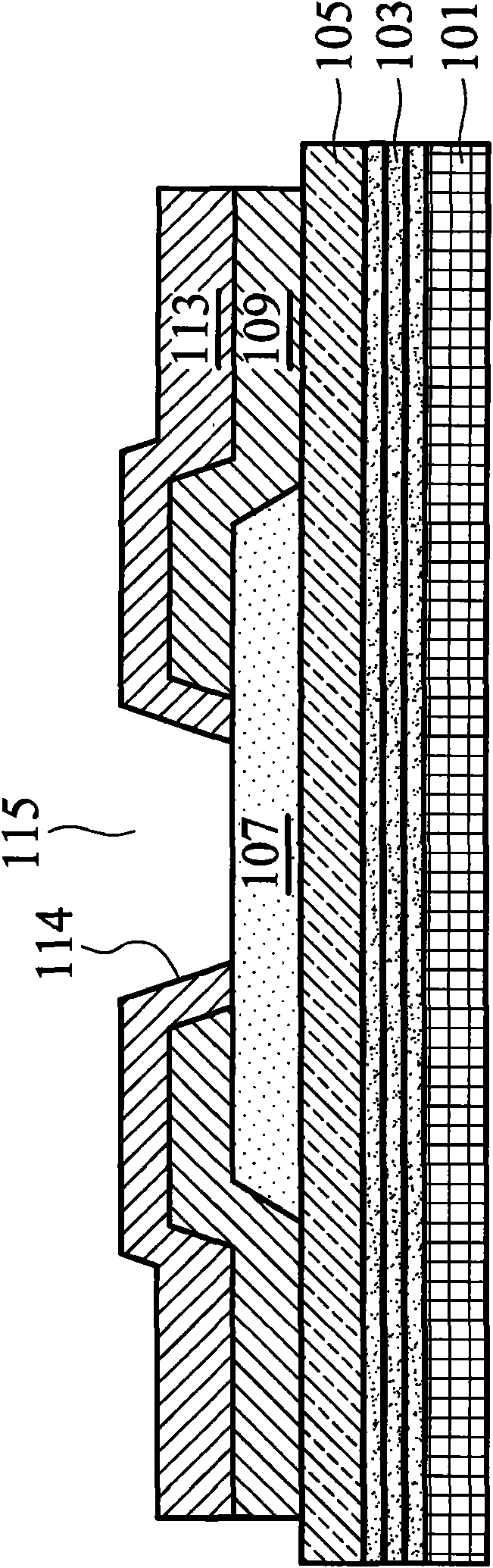

[0014] Figure 1 to Figure 8 These are structural cross-sectional views of different steps in the process of forming a semiconductor structure in one or more embodiments of the present invention. The "substrate" below refers to a semiconductor substrate on which a variety of layered structures and integrated circuit components are formed. The composition of the substrate may be silicon or a semiconductor compound such as gallium arsenide, indium phosphide, silicon germanium alloy, or silicon carbide. The layered structure can be a dielectric layer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com