Preparation method of ferroferric oxide/chitosan/TiO2 nanocomposite photocatalysis material

A technology of ferroferric oxide and photocatalytic materials, which is applied in the field of environmental pollution control, can solve the problems of photocatalytic performance impact, difficult recovery, and smaller specific surface area, and achieve high practical value, easy operation, and high synthesis safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

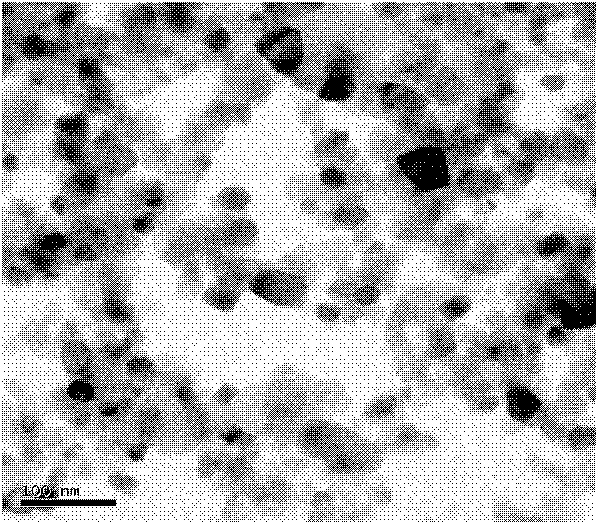

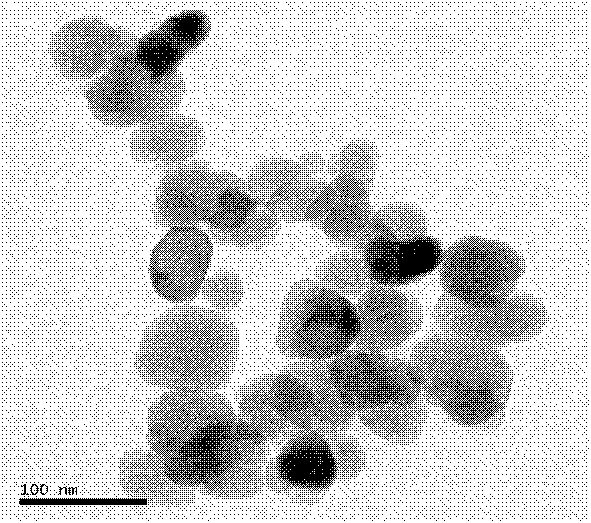

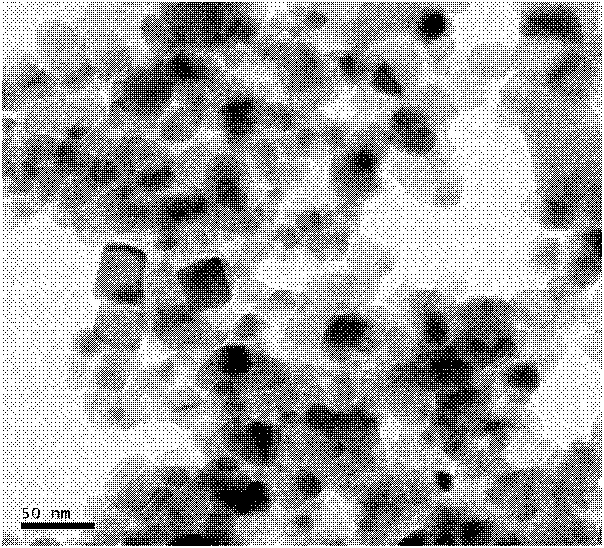

[0025] 1) Preparation of nano-magnetic ferriferric oxide: adopt solvothermal reduction method, use ethylene glycol as reducing agent, carry out partial reduction to ferric ion, use sodium acetate, polyethylene glycol as surfactant and preventive agent respectively Agglomeration aid, preparation of Fe 3 o 4 nanoparticles. First take 20mL of ethylene glycol into the beaker, add 0.5418g FeCl successively 3 , 1.8g sodium acetate and 0.5g polyethylene glycol PEG, magnetically stirred at room temperature for 1h, until the solid was fully dissolved and uniform, and a dark brown-yellow viscous liquid was obtained; the liquid was transferred to a high-pressure reaction lined with 25ml polytetrafluoroethylene In the kettle, heat it up to 200°C in an electric oven, keep it warm for 12 hours, and then cool it down to room temperature naturally; after taking out the solution in the kettle, wash it with absolute ethanol for several times, then wash it with deionized water for several time...

Embodiment 2

[0029] 1) Preparation of nano-magnetic ferriferric oxide: adopt solvothermal reduction method, use ethylene glycol as reducing agent, carry out partial reduction to ferric ion, use sodium acetate, polyethylene glycol as surfactant and preventive agent respectively Agglomeration aid, preparation of Fe 3 o 4 nanoparticles. First take 25mL of ethylene glycol into the beaker, add 0.6012g of FeCl successively 3 , 2.0g sodium acetate and 0.7g polyethylene glycol PEG, magnetically stirred at room temperature for 1.5h, until the solid was fully dissolved and uniform, and a dark brown viscous liquid was obtained; the liquid was transferred to a 25ml polytetrafluoroethylene-lined high-pressure In the reaction kettle, heat it up to 180°C in an electric oven, keep it warm for 9 hours, and then cool it down to room temperature naturally; after taking out the solution in the kettle, wash it with absolute ethanol for several times, then wash it with deionized water for several times, and t...

Embodiment 3

[0033] 1) Preparation of nano-magnetic ferriferric oxide: adopt solvothermal reduction method, use ethylene glycol as reducing agent, carry out partial reduction to ferric ion, use sodium acetate, polyethylene glycol as surfactant and preventive agent respectively Agglomeration aid, preparation of Fe 3 o 4 nanoparticles. First take 40mL of ethylene glycol into the beaker, add 0.4500g of FeCl successively 3 , 1.6g sodium acetate and 0.6g polyethylene glycol PEG, magnetically stirred at room temperature for 0.5h, until the solids were fully dissolved and uniform, and a dark brown viscous liquid was obtained; the liquid was transferred to a 25ml polytetrafluoroethylene-lined high-pressure In the reaction kettle, heat it up to 250°C in an electric oven, keep it warm for 10 hours, and then cool it down to room temperature naturally; after taking out the solution in the kettle, wash it with absolute ethanol for several times, then wash it with deionized water for several times, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com